7 MAINTENANCE

74

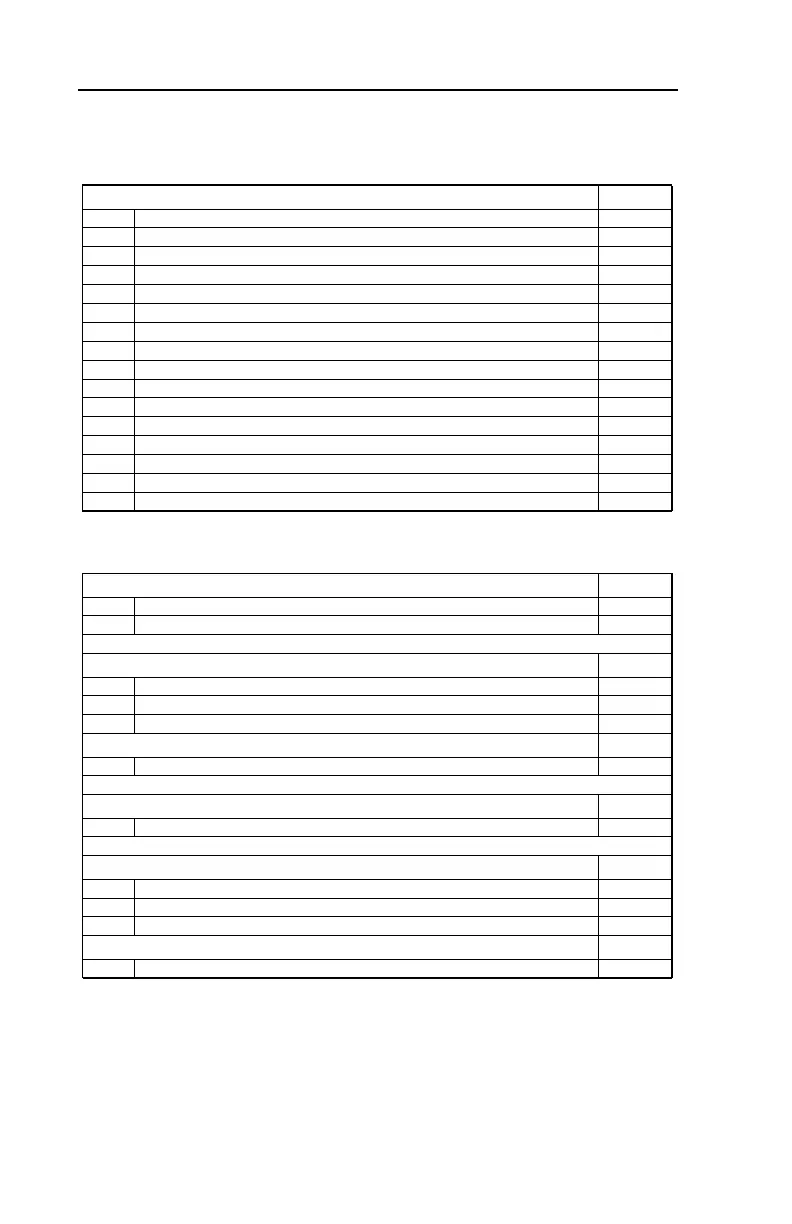

7.3 Maintenance Intervals

7.3.1 Daily Maintenance Tasks

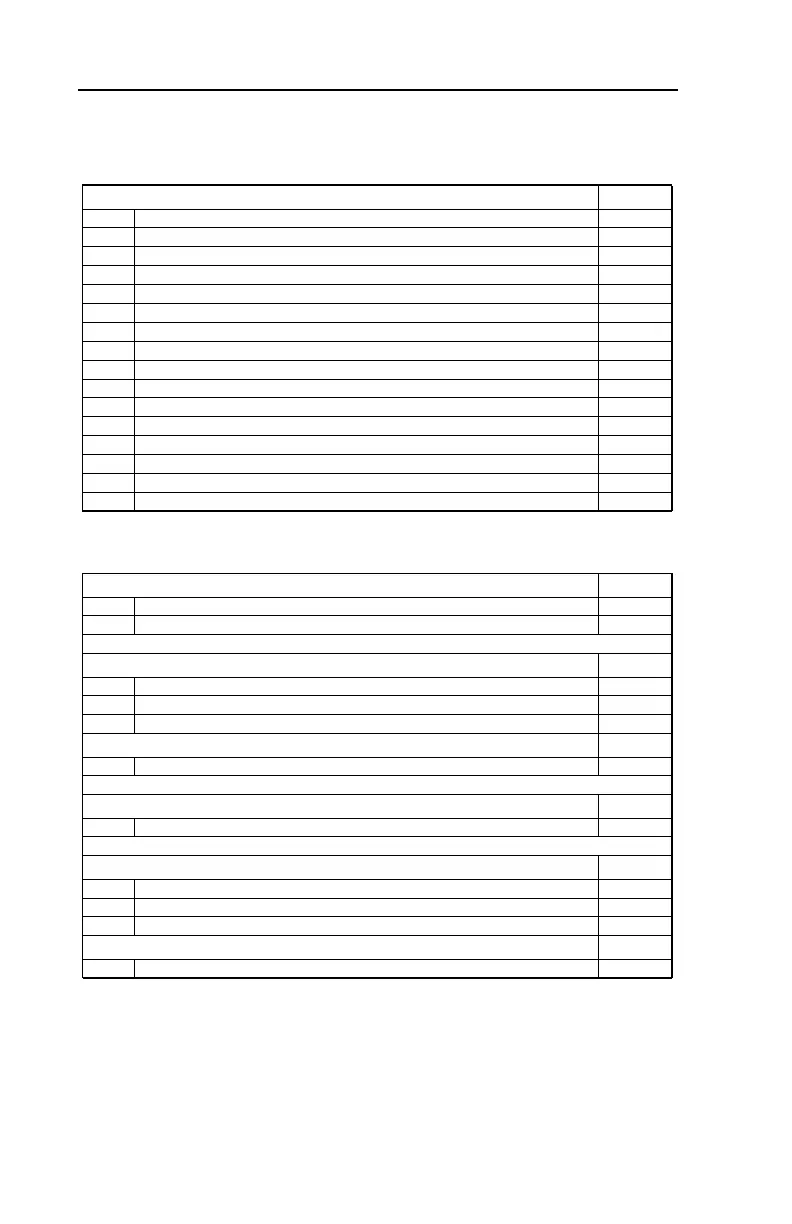

7.3.2 50-1000 hour Tasks

Page

1 Check hydraulic oil level (figure 7.7-3, p-78) 78

2 Check engine oil level 76

3 Check fuel level (gauge screen in Operator Interface) 37

4 Check track tension / condition 81

5 Check accessory belt for presence / tension / condition 79

6 Check for proper control operation 40

7 Check safety circuit for proper operation 55

8 Check for proper switch and lighting operation 37

9 Check display for air filter fault message, service as required 84-85

10 General visual check for cracks, damage, completeness 20,55

11 Check for leaks in hoses, tubes, valves, pumps, cylinders, etc. 18,27,55

12 Check display for water in fuel fault message, drain as required 80

13 Lubricate all grease points 75

14 Inspect / clean the coolers and engine compartment / chassis 86-87

15 Inspect / clean undercarriages (as needed) 81

16 Inspect / replace missing / damaged safety signs 12,13

Dail

Page

1 Inspect drive sprocket rollers (replace as needed) 83

2 Replace engine oil and filter (initial break-in service only) 77

Page

1 Replace hydraulic filter(s) 79

2 Check accessory belt(s) tension / condition (A/C if equipped) 79

Page

1 Replace engine oil & filter 77

Page

1 Replace fuel filter elements 80

Page

1 Replace hydraulic oil 78

2 Replace engine coolant (use SCA additive, see engine manual) 86

Page

1 Replace oil separator element 88

Every 1500 operating hours

Every 50 operating hours

Every 250 operating hours

Every 500 operating hours

Every 1000 operating hours

Every 400 operating hours

RT-40 US O&M

0404-766 2019-05

Loading...

Loading...