7 MAINTENANCE

86

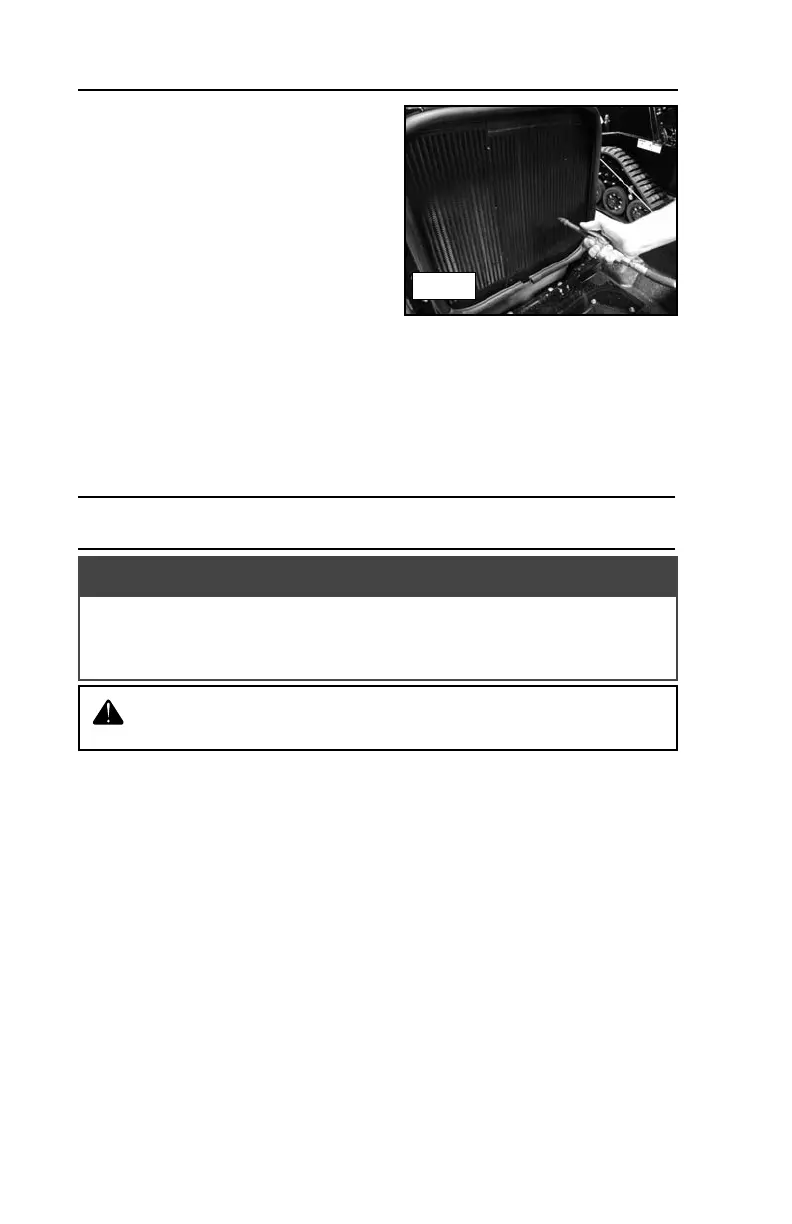

7.17 Radiator / Oil Cooler Cleaning

The radiator and oil cooler must be clean to

ensure proper operation. Engine and

hydraulic system overheating, damage and

even failure can result if the radiator/oil

cooler is not kept clean. A pressure washer

or compressed air both work well to blow

debris clear of the fins in the coolers.

To clean radiator / oil cooler:

1. Shut the machine down as described in section 5.12. Allow the machine to

cool thoroughly.

2. Open the hood to access the cooler (fig. 7.17-1).

3. Thoroughly clean all coolers with a pressure washer or compressed

air. Wear any appropriate safety clothing. Direct spray through the cooler as

shown. (fig. 7.17-1).

Note: If hydraulic oil or engine coolant temperature warnings occur during

operation, clean coolers more often.

7.18 Engine Coolant Change

1. Shut the machine down as described in section 5.12 and allow it to cool

thoroughly, then open the hood to access the cooler assembly.

2. Open the drain valve (item 1, fig. 7.18-1) and drain the old coolant into a

suitable catch container. Dispose according to mandates.

3. Close the drain valve and tighten, then add coolant (with SCA additive,

see engine manual) into the radiator through the fill neck until full.

4. Warm the engine to operating temperature, then turn the engine off, remove

the key and allow the machine to cool.

5. Check the coolant level, and top off (repeat steps 4 and 5 until all air has

been purged and the level is full when cold).

In dusty applications check and clean the coolers and chassis often to

avoid overheating and prevent fires.

Make sure water nozzle is at least 12 in. (30.5 cm), for air 8 in. (20.3 cm) from

the cooler and that the spray is directed straight through the cooler or the cool-

ing fins may be damaged (bent over) which will decrease cooling performance.

NOTICE

RT-40 US O&M

0404-766 2019-05

7.17-1

Loading...

Loading...