7 MAINTENANCE

79

7.8 Hydraulic Filter Change

The hydraulic filters should be changed every 250 hours. Hydrostatic components

require extremely clean oil in order to have a long service life. Use caution when

changing the hydraulic filter. Before beginning the procedure, make sure the

machine is in a clean working environment. Take any necessary measures to pre-

vent dirt or debris from entering the hydraulic system.

To change the hydraulic filter:

1. Shut the machine down according to the procedure in section 5.12.

2. Allow the machine to cool, then release any residual pressure in the

hydraulic system by following the procedure in section 4.7 of this manual.

3. Lower the forward access panel to access the hydraulic filter from the

underside of the machine (item 2, fig. 7.7-2).

4. Clean around the filter, then thread the filter off and replace it.

Dispose of the used filter according to local mandates.

5. Reverse step 3 to complete the procedure.

Note: Should a hydraulic hose or fitting need to be removed for maintenance or

service, always inspect it for damage prior to re-installation. If none is found it

may be reused; if damaged, replace it.

7.9 Accessory Belt(s)

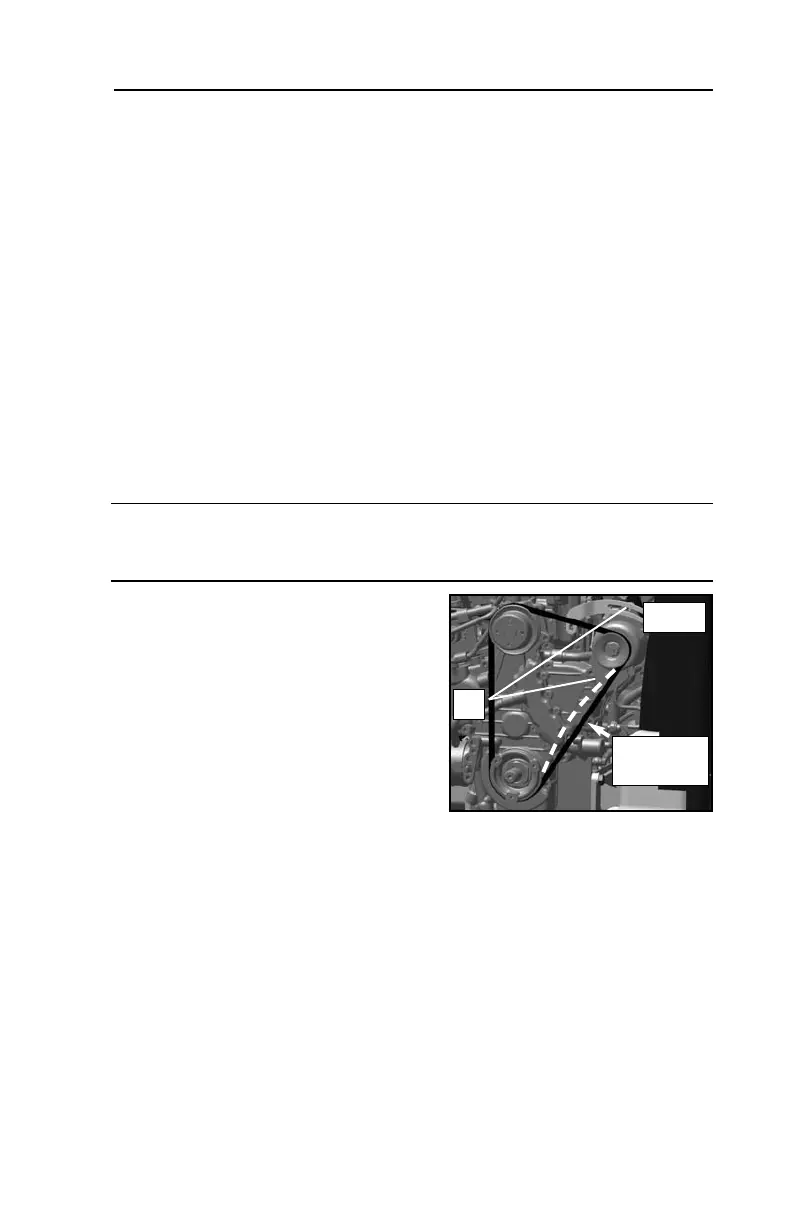

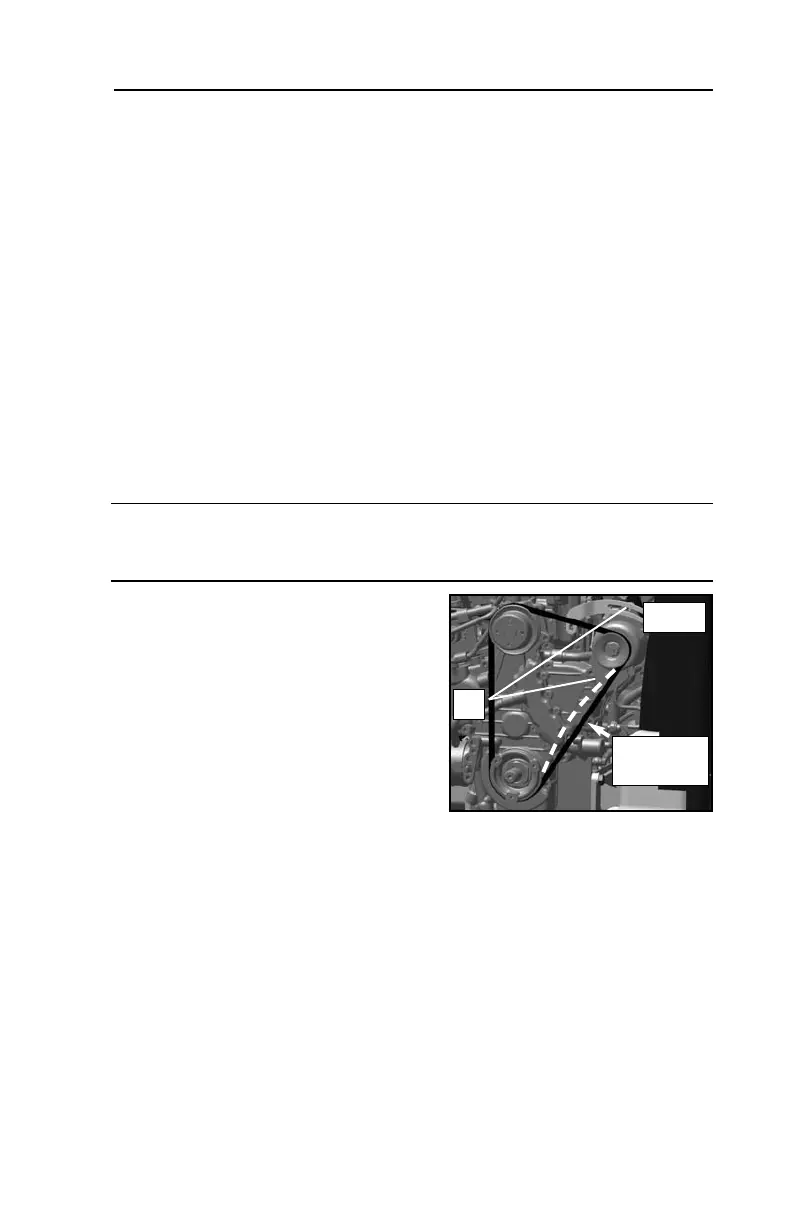

The accessory belt on the RT-40 should be

visually inspected daily. Replace if damaged.

To inspect:

1. Shut the machine down according

to the procedure in section 5.12,

allow the machine to cool.

2. Open the hood at the rear of the

machine.

3. Visually inspect the belt. If it appears loose, apply moderate thumb pressure

to the belt (fig. 7.9-1). If it deflects more than 0.39 - 0.47 in. (10-12mm),

loosen alternator fasteners (A) and use a lever between the engine block

and alternator to increase tension until within limits. Tighten fasteners (A).

Air Conditioning

The optional air conditioning system is driven by a belt (located beneath the seat).

Visually inspect the belt at 250 hours for tension, condition and presence.

To inspect, perform step 1 above, then:

1. Remove the bolts securing the front of the seat to the mounting bracket.

2. Disconnect the seat harness, then carefully lift and remove the seat and

underseat panel to inspect. Reverse steps 1-2 to complete the procedure.

RT-40 US O&M

0404-766 2019-05

7.9-1

Apply force

13.2-15.4 lbs

A

Loading...

Loading...