Speed N° 1

Not recommended

Speed N° 2

- Radiator

Speed N° 3

- Radiator

- Floor heating

system

- Fan convector

2.8 Connecting the heating

circuit hydraulically

2.8.1 General

The connection must comply with good trade practice

according to local building regulations.

The heating circulating pump is built into the

hydraulic unit.

Connect the central heating pipes to the appliance,

complying with the direction of circulation.

The pipe between the heat pump and the heat collector

must be at least one inch in diameter (26x34 mm).

Calculate the diameter of the pipes according to the

ow rates and the lengths of the hydraulic systems.

Tightening torque : 15 to 35 Nm.

Use union connectors to facilitate removing the

hydraulic unit.

Preferentially use connection hoses to avoid transmitting

noise and vibrations to the building.

Connect the drains from the drain valve and the safety

valve to the main sewer system.

Reminder: Seal everything when tting in accordance

with prevailing trade practice for plumbing work:

- Use suitable seals (bre seals, o-rings).

- Use Teon tape or hemp.

- Use sealing paste (synthetic depending on the case).

The use of glycol is not necessary.

If you are using a glycol/water mix, provide for an annual

check on the quantity of glycol. Use monopropylene

glycol only. Never use monoethylene glycol.

In certain installations, the presence of different metals

can cause corrosion problems; the formation of metal

particles and sludge in the hydraulic circuit is then seen.

In this case, it is advisable to use a corrosion inhibitor in

the proportions indicated by its manufacturer.

It is also necessary to ensure that the treated water

does not become aggressive.

2.8.2 Rinsing out the installation

Before connecting the hydraulic unit to the installation,

rinse out the heating system correctly to eliminate

any particles that may affect the appliance's correct

operation.

Do not use solvents or aromatic hydrocarbons (petrol,

parafn, etc.).

In the case of an old installation, provide a sufciently

large decanting pot with a drain on the return from the

boiler and at the lowest point in the system in order to

collect and remove the impurities.

Add an alkaline product to the water and a dispersant.

Rinse the installation several times before lling it

denitively.

2.8.3 Filling and purging the installation

Check the pipe xings, the tightness of the connectors

and the stability of the appliance.

Check the direction in which the water is circulating and

that all the valves open.

Proceed to ll the installation.

Do not operate the circulating pump while lling. Open

all the drain valves in the installation and the bleeder

valve for the hydraulic unit to remove the air contained

in the conduits.

Close the drain and bleeder valves and add water until

the pressure in the hydraulic circuit reaches 1,5 bars.

Check that the hydraulic circuit has been purged

correctly.

Check that there are no leaks and that the circulating

pumps are not seized (if need be, release them).

After the "Start-up" stage (see page 28), once the

machine has started, purge the hydraulic unit again.

2.8.4 Connecting a fan-convectors circuit

It must be installed on this circuit a buffer tank

(minimum capacity: 50 liters).

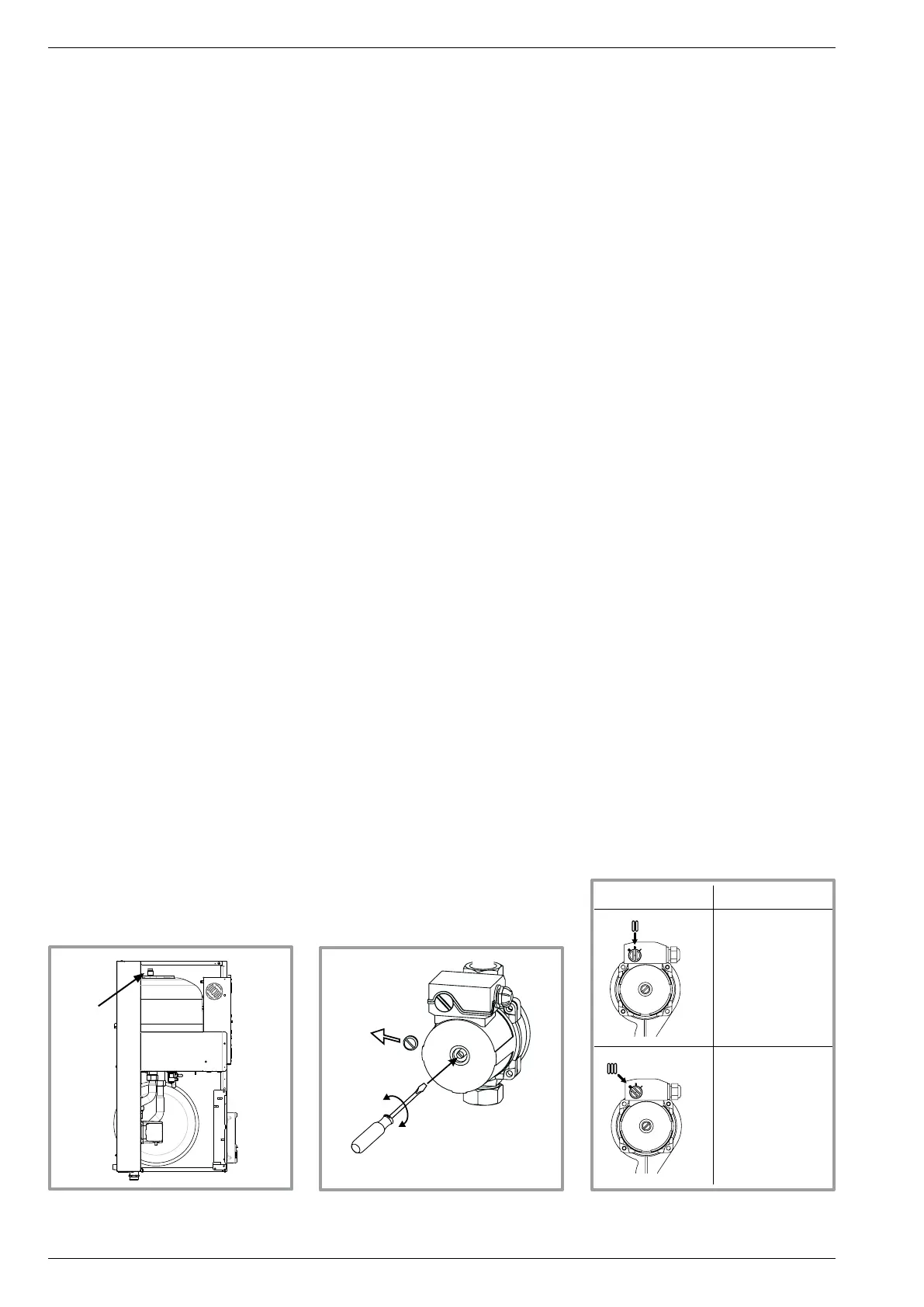

gure 21 - hydraulic unit

bleeder valve

P

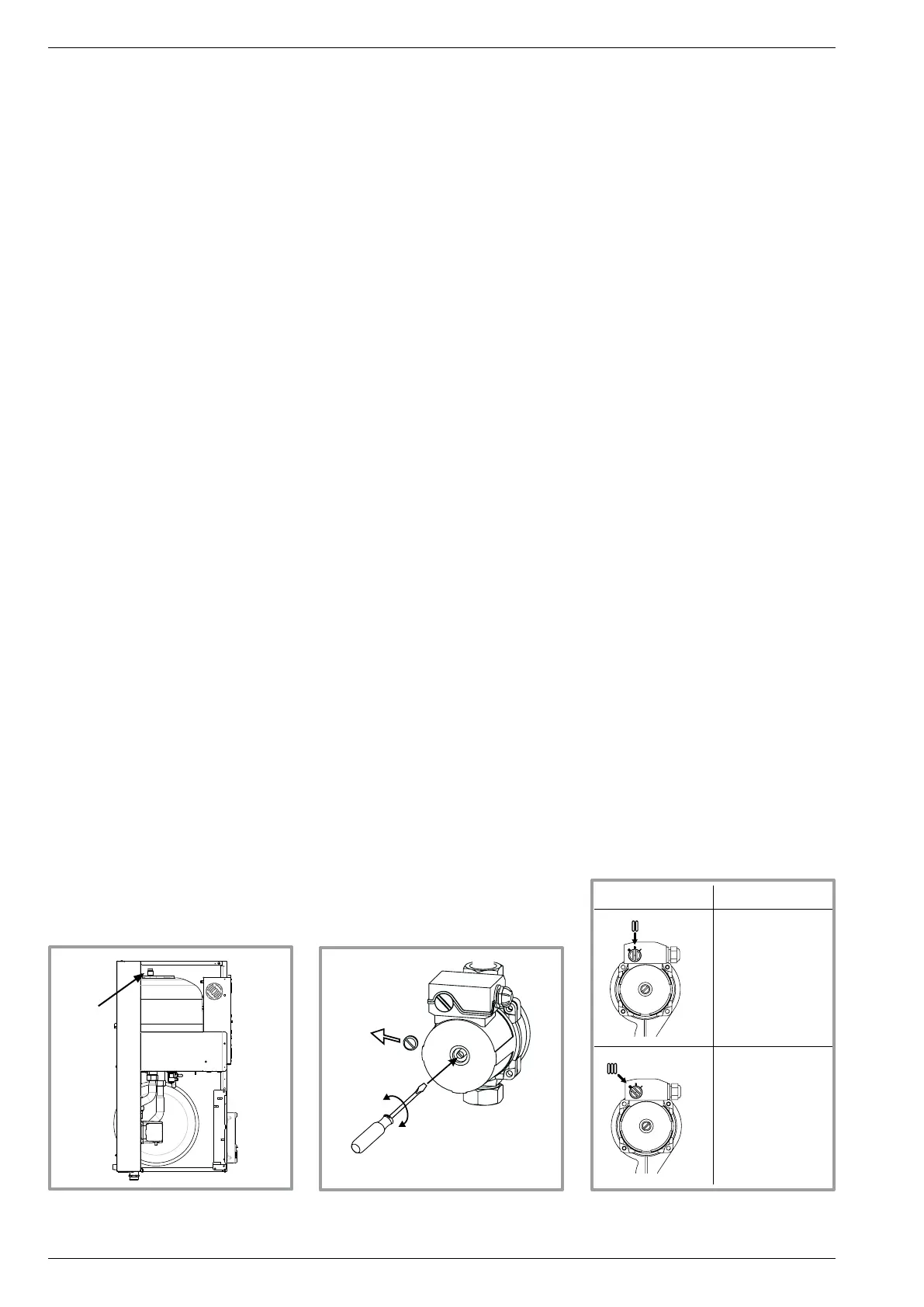

gure 22 - Release

of the circulation pump

gure 23 - Recommended

circulation speed

Installation and operation manual "1397 - EN"

Heat pump split single service alféa Evolution

- 20 -

Loading...

Loading...