2.7 Filling the installation with gas

" This operation is reserved for installers familiar

with the legislation for handling refrigerants.

" Creating a vacuum with a vacuum pump is

essential.

" Never use equipment used beforehand with any

refrigerant other than a HFC.

2.7.1 Creating a vacuum and

lling the refrigeration connections with gas

• First seal test

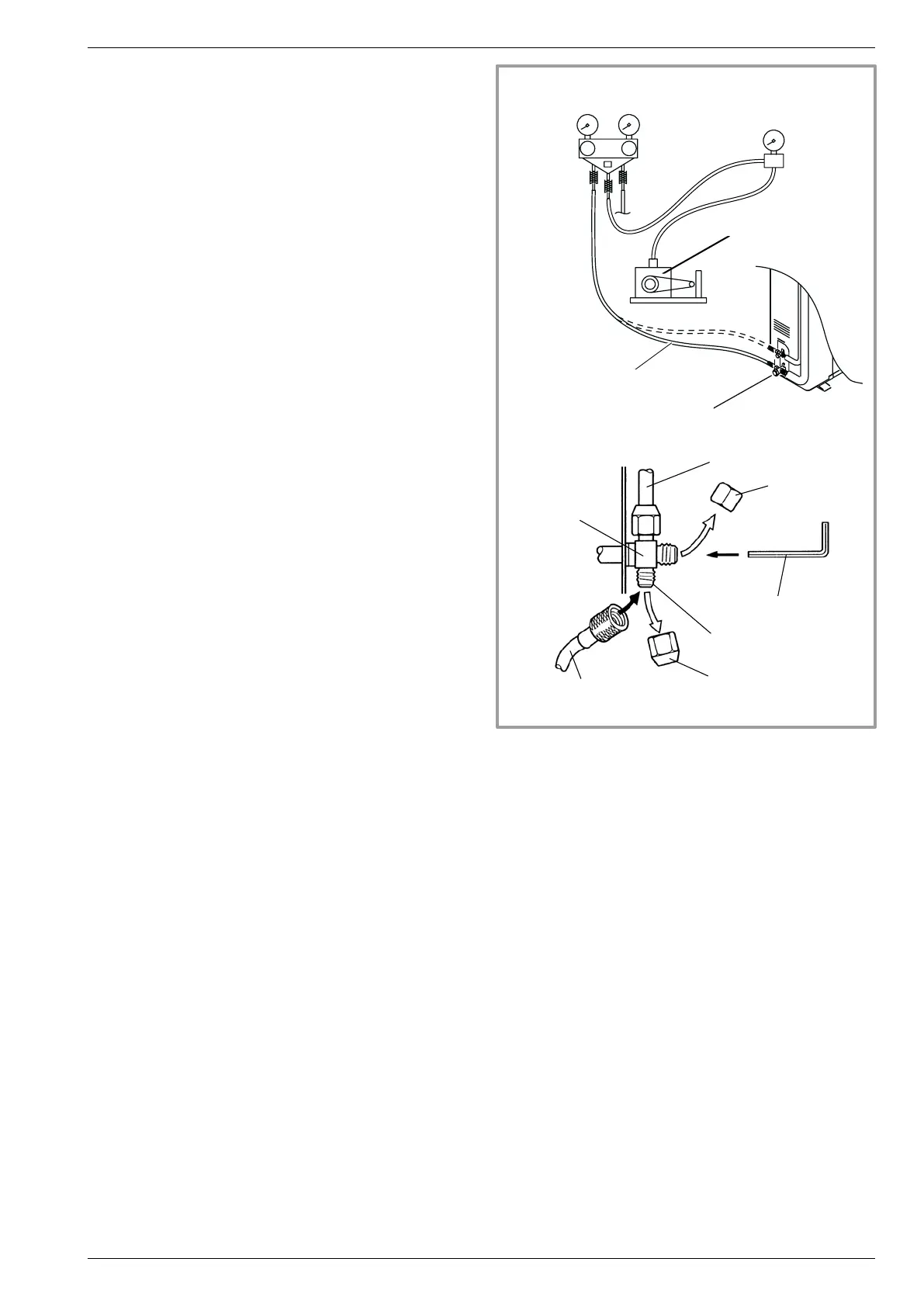

- Remove the protective plugs (B) from the charging

hole (Schrader) in the gas valve (large diameter).

- Connect the hose to the manifold,

- Connect the bottle of nitrogen to the manifold.

- Pressurize the refrigerant circuit to 10 bar with nitrogen.

- Leave the circuit under pressure for half a day.

- Check that the pressure has not fallen.

- Look for and repair any leaks, and then recommence

the test.

- Once the pressure has remained steady for a few

hours, empty the nitrogen.

• Creating a vacuum and lling the refrigeration

connections with gas

- Connect the vacuum pump to the manifold.

- Create a vacuum until the residual pressure in the

circuit falls below 0,01 bar.

- Let the pump continue to operate for another 30

minutes after reaching the vacuum.

- Close the blue valve on the set of manometers and

then stop the vacuum pump without disconnecting

any of the hoses in place.

- Leave for at least half a day.

If after this time the pressure has risen, there

is a leak. Find and repair the leak and then

recommence vacuum testing.

When the pressure remains steady for a few

hours after stopping the vacuum pump, the circuit

can be considered airtight.

- Remove the access plugs (A) from the valve controls.

- First of all fully open the small valve and then the

large one using a hex key (counterclockwise direction)

without forcing excessively against the stop.

- Remove the blue hose rapidly.

- Ret the 2 plugs and tighten them to the recommended

tightening torque gure 18 page 17.

The outdoor unit does not contain any additional

refrigerant, enabling the installation to be purged.

Flushing is strictly forbidden.

2.7.2 Sealing test

Once the refrigeration circuit has been gassed as

described above, check that all the refrigeration

connectors are gas-tight:

6 connectors for models Evolution 5 and Evolution 6, 5

connectors for model Evolution 8 and 4 connectors for

models Evolution 10, Evolution 13 and Evolution 16.

The sealing test must be performed with an approved

gas detector. If the arings have been made correctly,

there should be no leaks.

" If there is a leak:

- Bring the gas into the outdoor unit (pump down),

- Make the connection again,

- Repeat the commissioning procedure.

Lo

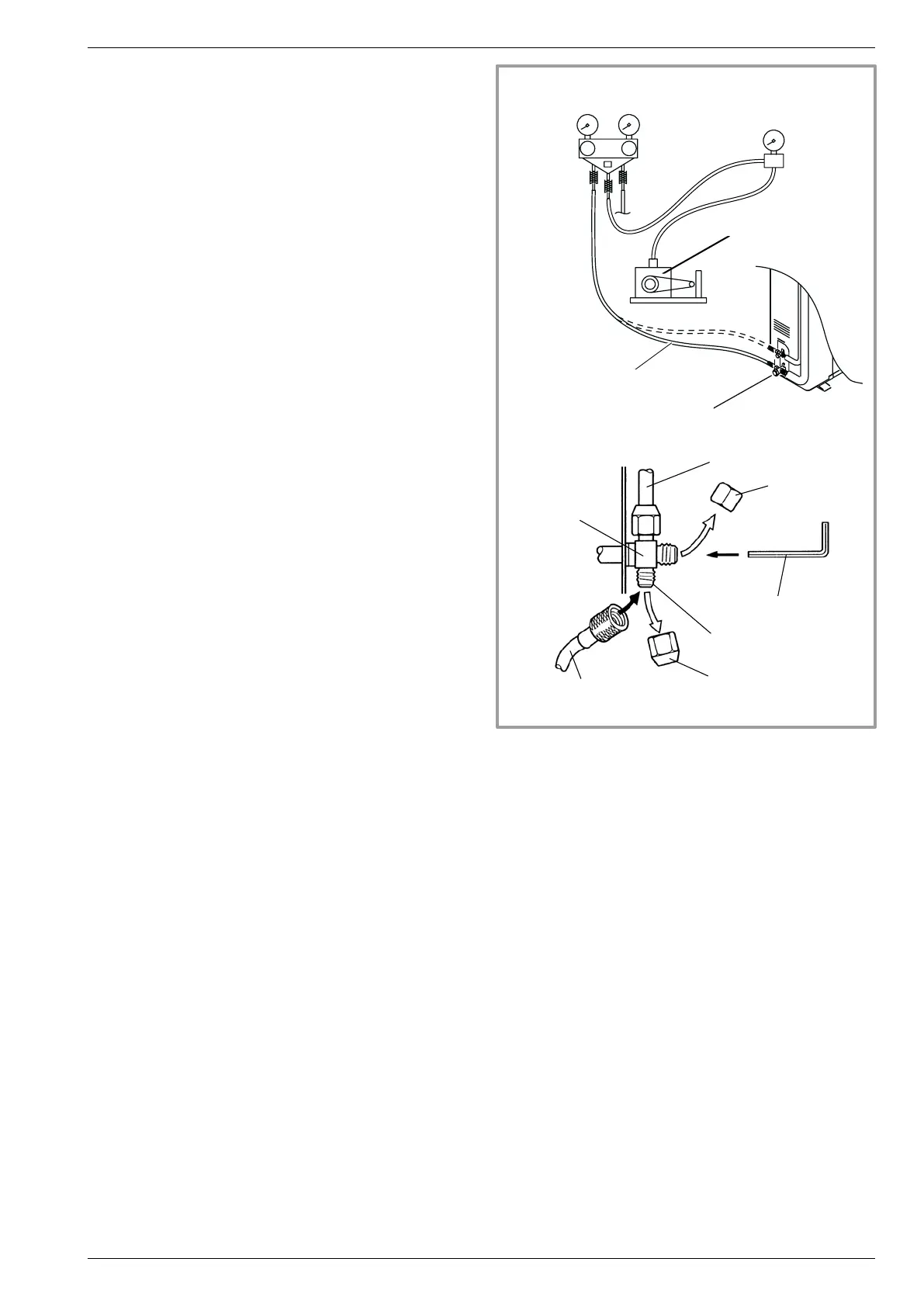

Hi

Jeu de manomètres

(manifold)

Pompe à vide

Flexible de service

Basse

pression

Haute

pression

Vanne “gaz” (gros diamètre)

Vacuomètre

Liaison frigorifique

Bouchon (A)

Clé hexagonale de 4 mm

Vanne 3 voies

Orifice de charge

Bouchon (B)

Flexible de service (bleu)

muni d’un poussoir de valve

gure 20 - Extraction under vacuum and gassing

Clé hexagonale/Allen

de 4 mm

Manometer kit

(manifold)

Vacuum pump

Service hose

Service hose (blue) tted with

valve push-button

Plug (B)

Plug (A)

Hex / Allen key 4 mm

Load orice

Refrigeration

connection

3-way valve

Low

pressure

High

pressure

Gas valve (Large diameter)

Vacuum meter

Installation and operation manual "1397 - EN" - 19 -

Heat pump split single service alféa Evolution

Loading...

Loading...