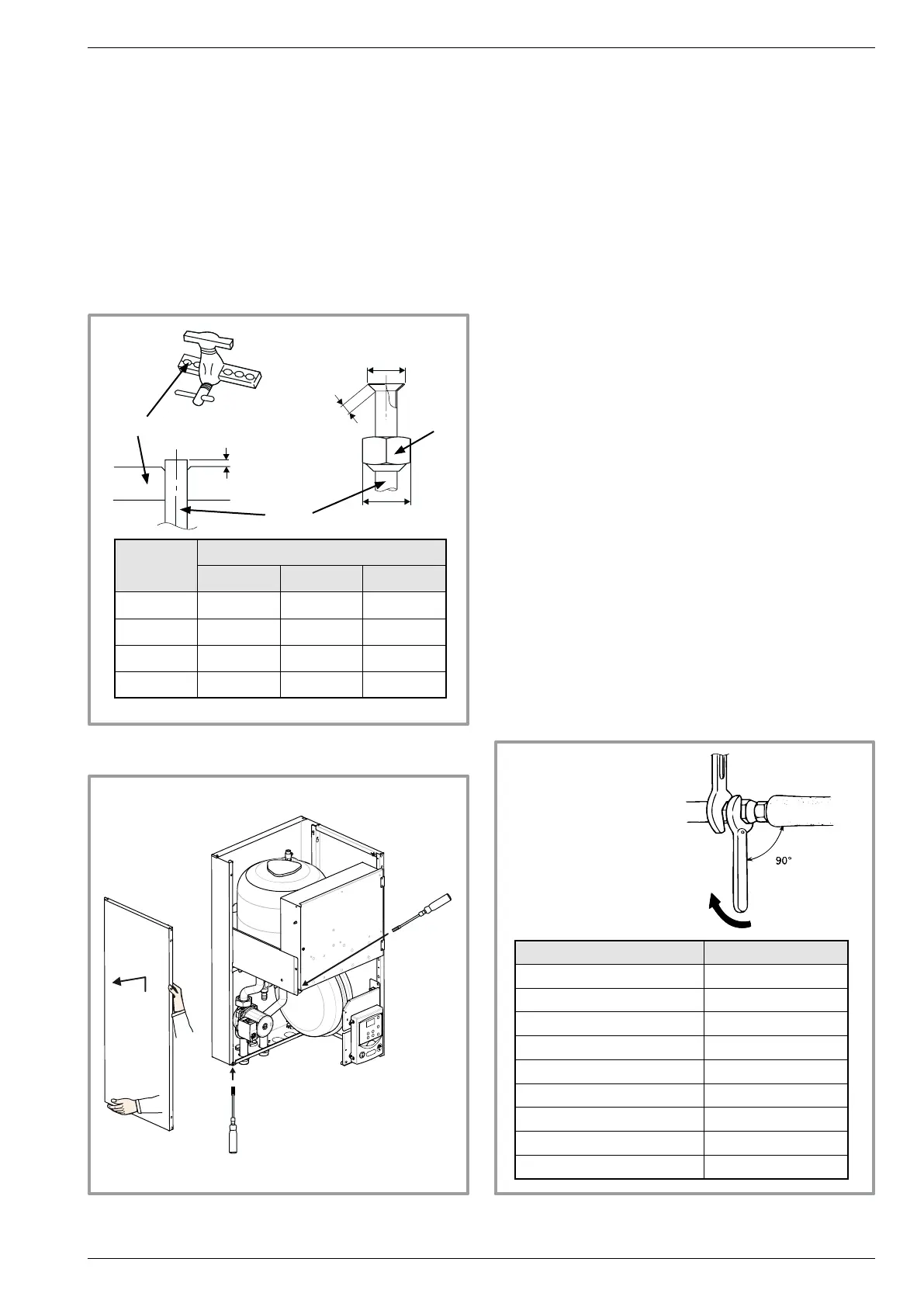

2.6.4 Creating the arings

- Cut the pipe to an appropriate length with a pipe-cutter

without deforming it.

- Carefully deburr it, holding the pipe towards the bottom

to avoid introducing lings into the pipe.

- Remove the ared connection nut situated on the

valve to be connected and slip the pipe into the nut.

- Proceed to are, letting the pipe overow the aring

tool.

- After aring, check the condition of the working radius

(L). This must not show any scratch or trace of any

fracturing. Also check the dimension (B).

Flaring tool

Hose

Flare

nut

B

L

C

ø hose Dimensions in mm

L B

0

/

-0,4

C

6,35 (1/4") 1,8 to 2 9,1 17

9,52 (3/8") 2,5 to 2,7 13,2 22

12,7 (1/2") 2,6 to 2,9 16,6 26

15,88 (5/8") 2,9 to 3,1 19,7 29

4

3

B

3

B

gure 17 - Removing the left-hand panel

2.6.5 Shaping the refrigeration pipes

The refrigeration pipes must be shaped only on a

bending machine or with a bending spring in order to

avoid any risk of crushing or breaking them.

" Warning !

• Remove the insulation material locally to bend the

pipes.

• Do not bend the copper to any angle over 90°.

• Never bend pipes more than 3 times in the same

position otherwise traces of fracturing may appear

(from strain-hardening the metal).

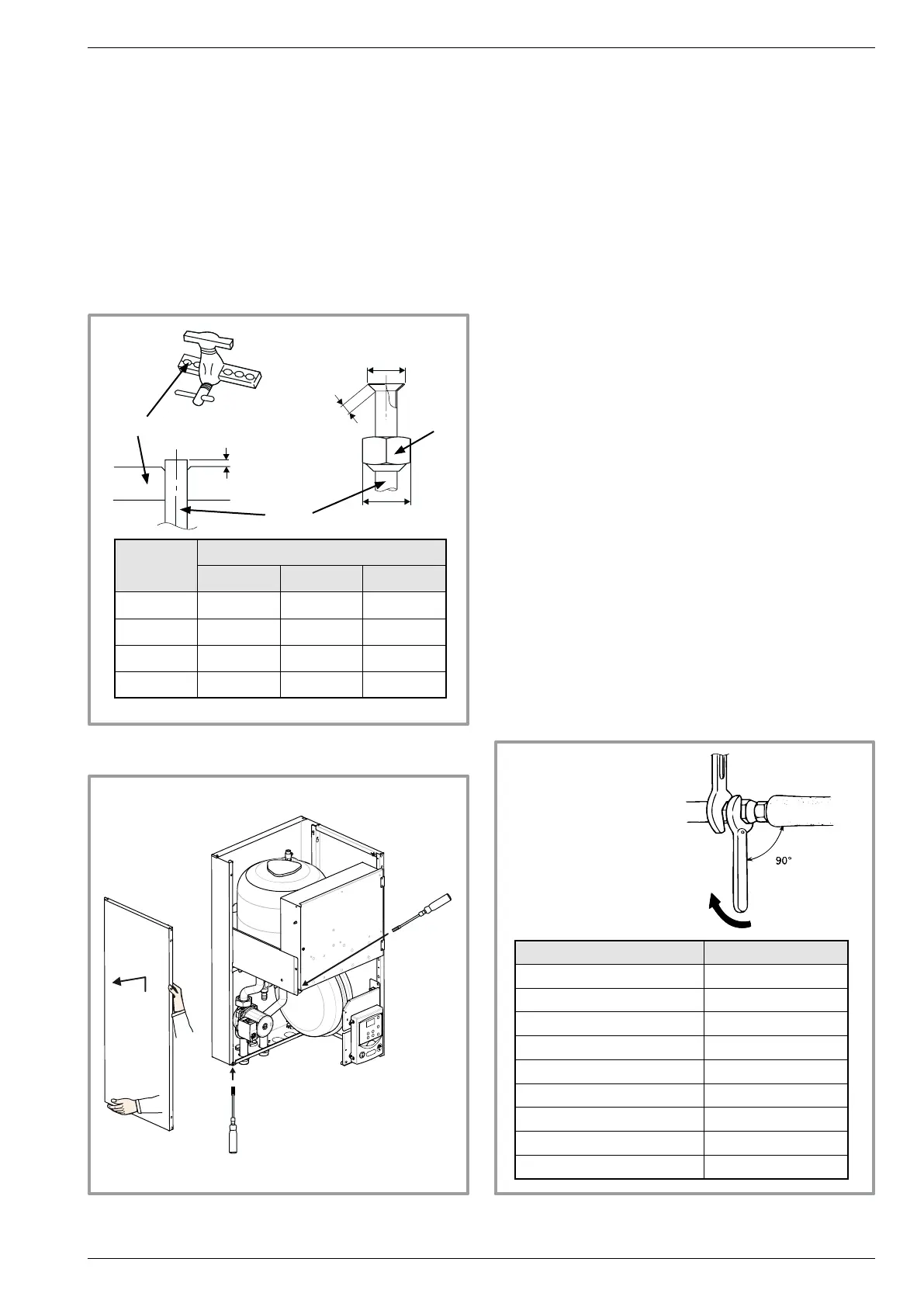

2.6.6 Connecting the ared connections

" Take particular care positioning the tube

opposite its connector so as not to risk damaging

the threads. A carefully aligned connector can

be tted easily by hand without much force

being required.

" The refrigeration circuit is very sensitive to dust

and humidity: check that the area around the

connection is clean and dry before removing the

plugs protecting the refrigeration connectors.

- Depending on the case, connect an adapter (reducer)

1/4''- 3/8'' or 1/2''- 5/8' (see gure 18).

- Remove the plugs from the pipes and the refrigeration

connections.

- Present the pipe to the ared connector and screw the

nut by hand while holding the connector with a wrench

until contact.

- Warning! Do not position the gas tube in front of the

circulation pump cleaning screw.

- Comply with the indicated tightening torques.

gure 18 - Tightening torque

Designation Tightening torque

Flare nut 6,35 mm (1/4") 14 to 18 Nm

Flare nut 9,52 mm (3/8") 33 to 42 Nm

Flare nut 12,7 mm (1/2") 50 to 62 Nm

Flare nut 15,88 mm (5/8") 63 to 77 Nm

Plug (A) 3/8", 1/4" 20 to 25 Nm

Plug (A) 1/2" 25 to 30 Nm

Plug (A) 5/8" 30 to 35 Nm

Plug (B) 3/8", 5/8" 10 to 12 Nm

Plug (B) 1/2", 1/4" 12,5 to 16 Nm

Holding wrench

Torque wrench

Installation and operation manual "1397 - EN" - 17 -

Heat pump split single service alféa Evolution

Loading...

Loading...