2.6 Refrigeration connections

" This appliance uses refrigerant R410A.

Comply with the legislation for handling refrigerants.

2.6.1 Rules and precautions

• After every intervention on the refrigeration circuit and

before nal connection, take care to replace the plugs

in order to avoid any pollution from the refrigeration

circuit.

• Tools

- Set of manometers with hoses exclusively reserved

for HFCs.

- Vacuum pump specially for HFCs.

- Provision on using tools that have been in contact with

HCFCs (R22 for example) or CFCs.

- Use of a traditional vacuum pump is authorized if, and

only if, it is tted with a non-return valve on the suction

side.

The manufacturer declines any liability with regard to the

guarantee if the above instructions are not observed.

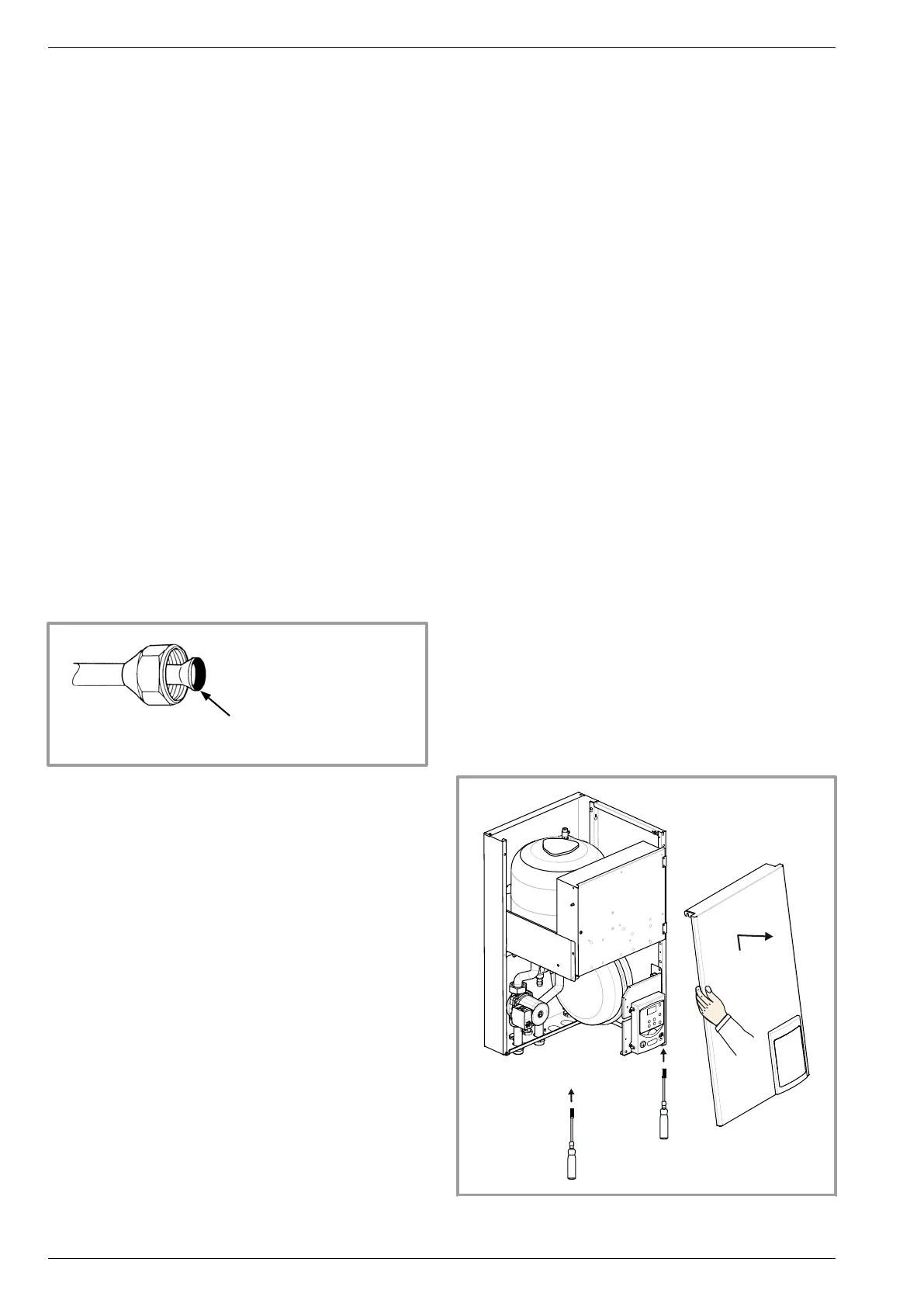

• Flared connections

" Lubrication with mineral oil (for R12, R22) is

forbidden.

- Only lubricate with polyolester refrigeration oil (POE).

If POE is not available, t without lubrication.

2.6.2 Refrigeration connections

The outdoor unit must be connected to the hydraulic

unit with copper pipes and connections (refrigeration

quality), insulated separately.

Comply with the pipe diameters and the permitted pipe

lengths (gure 13).

The minimum length of the refrigeration connections

is 5 m for correct operation.

The appliance will be excluded from guarantee if it is

used with refrigeration connections less than 5 m long.

Manipulate the pipes and take them through walls with

protective plugs in place.

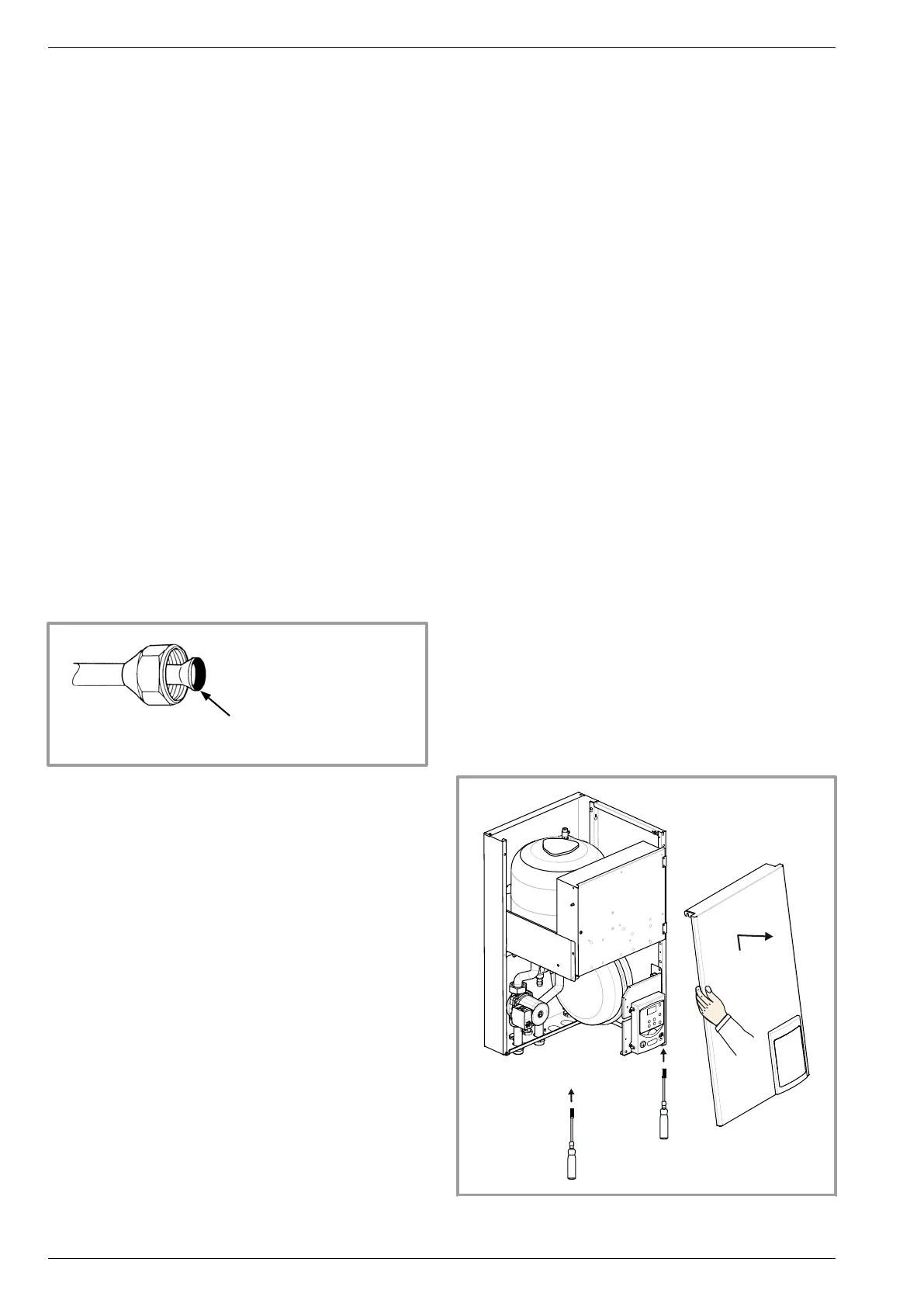

2.6.3 Accessing the hydraulic module’s

refrigerant connections

- Remove the front panel (2 screws A, gure 16).

- Remove the left-hand panel (2 screws B, gure 17).

Coat the ared surface with

POE refrigeration oil.

Do not use mineral oil.

• Brazing on the refrigeration circuit (if necessary)

- Silver brazing (40% minimum recommended).

- Brazing only under dry nitrogen internal ux.

• To eliminate any lings in the pipes, use dry nitrogen

to avoid introducing any humidity that may adversely

affect the appliances operation. In general, take every

precaution to avoid humidity penetrating into the

appliance.

• Proceed to insulate the gas and liquid pipes to avoid

any condensation. Use pipe insulators resistant to

temperatures over 90°C. In addition if the humidity

level in areas where the refrigeration pipes are

installed is expected to exceed 70%, protect the pipes

with pipe insulators. Use an insulating material thicker

than 15mm if the humidity level is 70~80%, and an

insulating material thicker than 20mm if the humidity

exceeds 80%. If the recommended thicknesses are

not observed under the conditions described above,

condensation will form on the surface of the insulation

material. Lastly, take care to use pipe insulators

whose thermal conductivity is 0.045 W/mK or less

when the temperature is 20°C. The insulation must be

impermeable to resist the passage of steam during the

defrosting cycles (breglass wool is prohibited).

1

A

1

A

2

gure 16 - Removing the front panel

Installation and operation manual "1397 - EN"

Heat pump split single service alféa Evolution

- 16 -

Loading...

Loading...