TPS Control EN User guide

© Atlas Copco Industrial Technique AB - 9836 5819 01

29

If you want to change the job, press MENU and select any of the available jobs with the up/down ar-

row keys. Press OK or SELECTto activate the job.

2. Position the tool in position 1. The LED backlight will remain white or flash green and white until the

position is reached, depending on the results of the previous tightening operation position. As soon as

the position is reached, the LED backlight will change to blue and the output enabling the screwdriver

will be activated.

3. Perform the operation for this position.

4. If the screwdriver transmits an OK signal, the position is marked as processed (the corresponding box

turns black) and the LED backlight will change to flashing green and white.

Note! For EBL RE-Drive, you need to retract the tool from the current position before moving to the

next position.

5. Move the tool to the next position. As soon as the next position is reached, the backlight will revert to

blue.

6. Repeat steps 4-7 until all positions have been processed.

7. When the tightening operation is completed, the box symbol indicates this by changing colour.

If you have set the parameter Enable Backstep to ON, a Back button will show as soon as at least one po-

sition has been completed. The Back button is used to enable a repetition of a tightening operation, even

in the event of an OK result.

If you want to stop the tightening operation, press the RESET button. Press Yes at the question Really

cancel the job?. The procedure will stop and the LED backlight will change to red. The procedure will be

displayed as NOK and the operation can be restarted by pressing the START button.

If the screwdriver transmits an NOK signal, the backlight will change to red and the tool will be disabled.

The next step in the procedure depends on how the unit is configured in regards to the parameters Ac-

knowledge NOK and NOK Max Count.

NOK acknowledgement not required: If NOK does not require an acknowledgement, the operator can im-

mediately repeat the tightening operation for this screw; however, the tool must first have left the position

of the current screw before the same screw is released again for processing. If the NOK Max Count pa-

rameter is set to any value except 0 (zero), the operator can only start the number of repeated attempts

set in the parameter value. If the number is exceeded, a signal is issued and the Pset must be reset.

NOK acknowledgement required: The operator must press the NOK key on the device or, if accordingly

configured, activate the external Acknowledge NOK input signal (for example, with a key switch). The po-

sition will be released for repeated processing after this acknowledgement has been signalled. If NOK ac-

knowledge is activated, the NOK Max Counter parameter will not be evaluated.

In both cases, the operations can be cancelled with the Reset button.

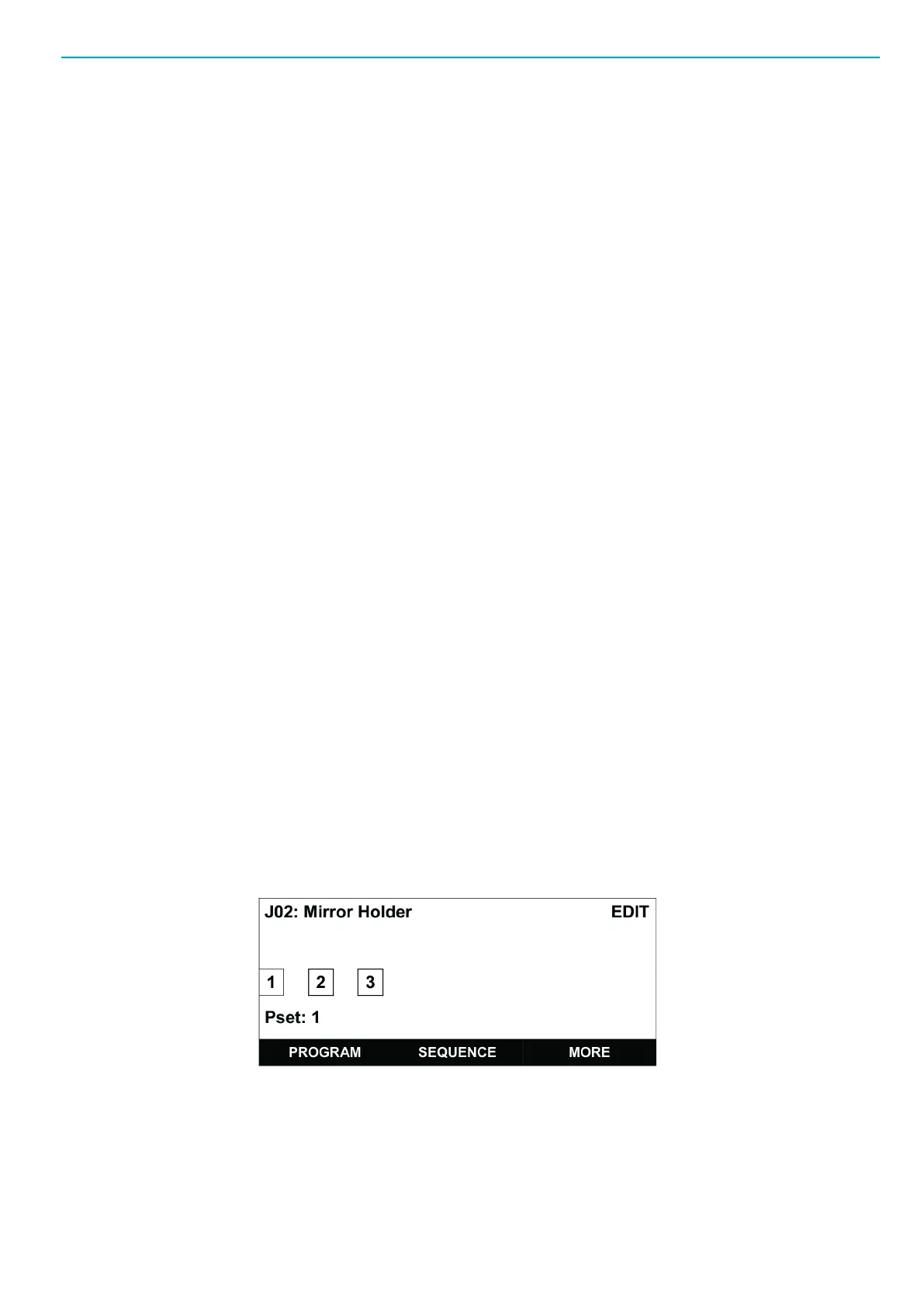

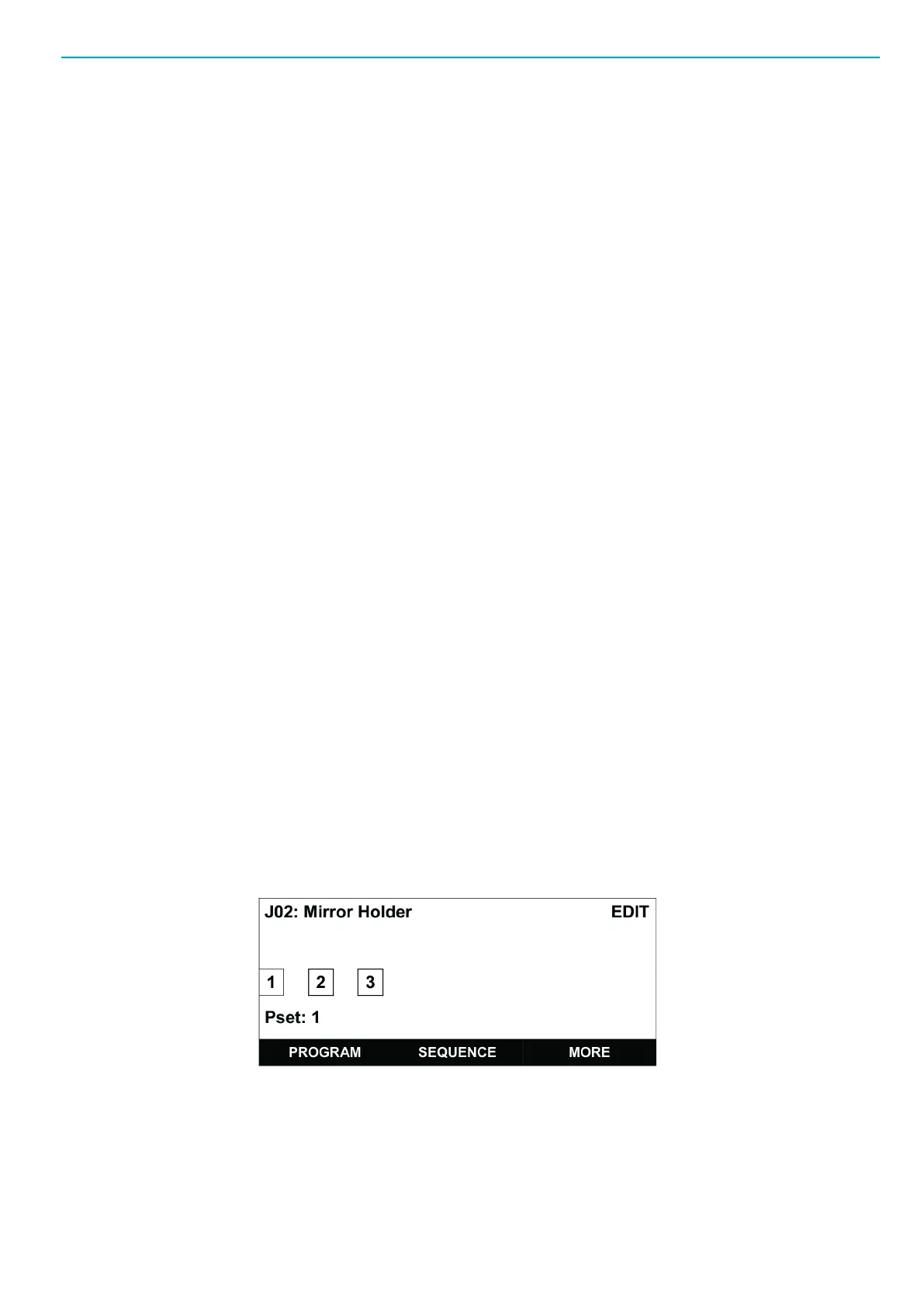

Changing existing job

The EDIT menu lets you process an already-existing job. The following functions can be executed with a

job in this area:

■

PROGRAM lets you re-program the positions again. Only the same number of positions that were

available before the job can be re-programmed.

■

SEQUENCE lets you set the position queries and position-specific output signals. Furthermore, the

Pset values can be subsequently changed for the specific positions.

■

MORE opens another menu, from which you can change the job name or completely delete a job.

■

Edit Job Name

Loading...

Loading...