5.2. LOAD CONTROL

When the permissible load on the work platform

is exceeded, the corresponding lights on the

control stations flash, an alarm sounds and all

the movements are stopped. The platform must

be partially discharged until the alarm stops.

If the overload was triggered by a collision with

an obstacle at a height, the platform may be

cleared using the auxiliary hydraulic group. This clearance procedure is strictly reserved for this

precise case.

1- Cut the diesel engine.

2- Use the auxiliary hydraulic group to make the appropriate clearance movement (See

Section 6.1.3 – Auxiliary hydraulic group). The telescope can only be lowered and

retracted.

3- Once the platform is cleared, restart the diesel engine and return the platform to low

position. Check that the platform or load control mechanism have not been damaged

before returning the machine into service.

-NOTE-

A cutout of all movements including those performed from the auxiliary group can be

configured in the system : Refer to §8.3.1 - Settings

5.3. CALIBRATION OF THE OVERLOAD PLATFORM SYSTEM

1. Put the machine on a firm and level surface; make sure the work

platform is horizontal.

2. Using the key switch select the upper or lower control panel

3. Check the maximum load allowed into the platform (manufacturer’s

plate).

4. Remove all tools and accessories from the work platform.

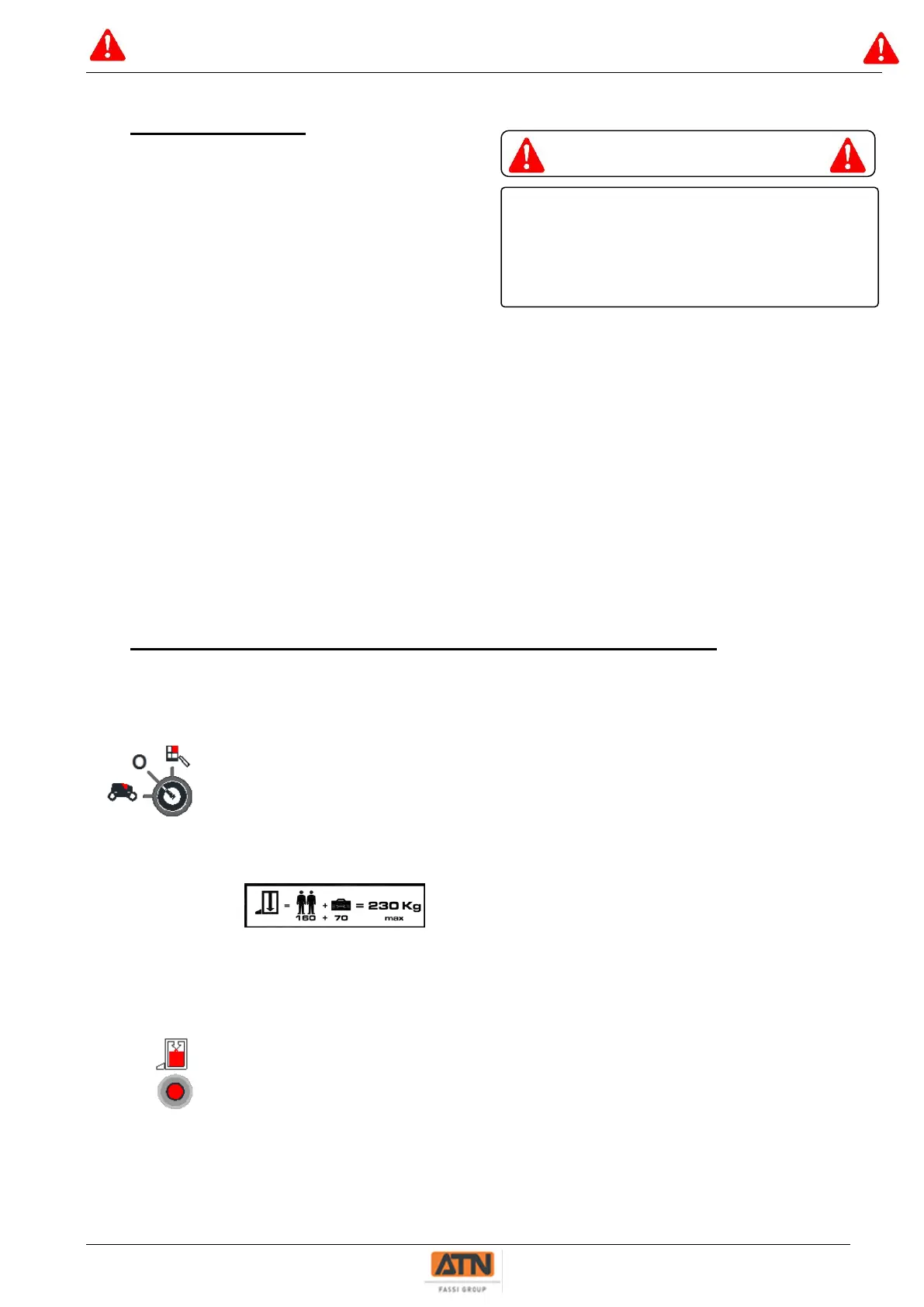

5. Place a test weight equal to the maximum platform capacity + 10 kg

(240kg).

6. The overload light must flash and the alarm must sound.

If the alarm does not sound, slowly loosen the load spring adjustment

nut in counterclockwise direction with 17mm wrenches until the alarm

stops.

7. From the ground, lift manually the platform by about 5cm, the alarm

must stop.

Loading...

Loading...