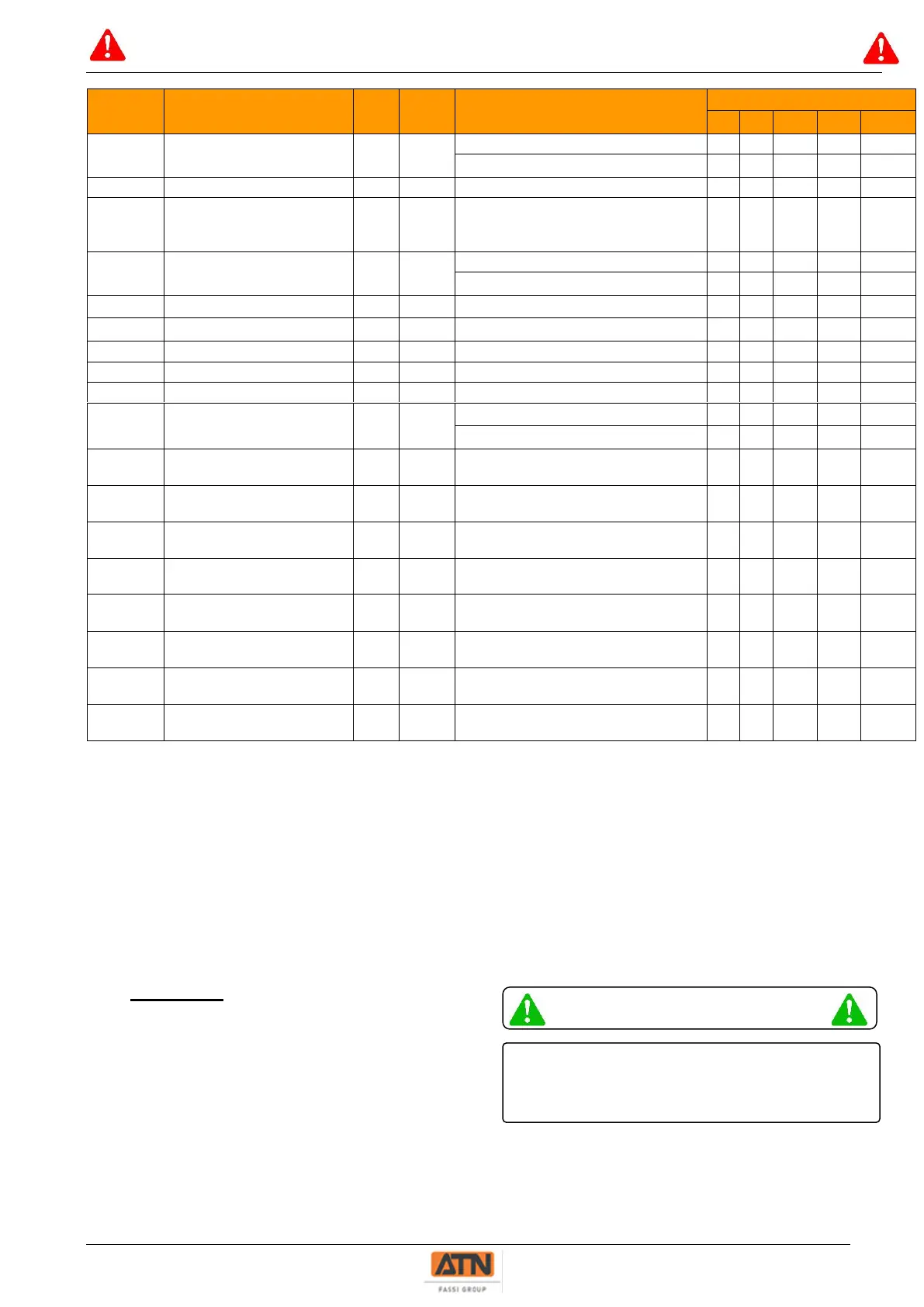

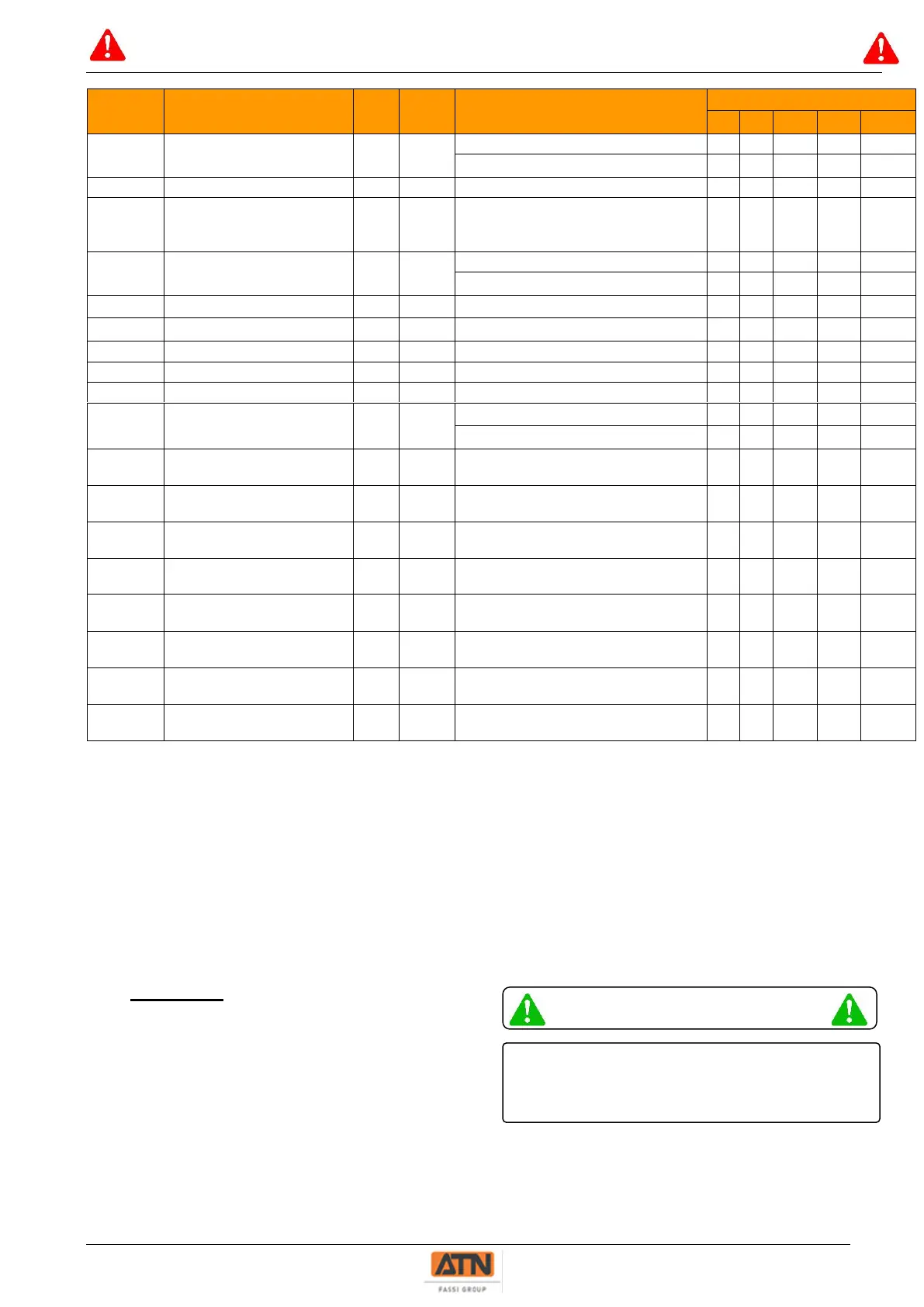

Notes:

J: At the beginning of each day or after each operator change.

(1): After the first 50 hours' operation.

(2): At the interval indicated or every 2 years.

(3): At the interval indicated or every year.

(4): The air filter body has a clogging indicator. Clean the filter if the indicator turns red before

the indicated interval.

(5): The oil level must appear in the level light window.

(6): Turn the structure to distribute the grease.

7.3. WHEELS

The wheel tightening must be checked after the

first 50 hours' use and then every 3 months or

every 100 hours' operation.

• Wheel replacement

To avoid harming the machine's stability, the wheels may only be replaced by wheels with

identical characteristics (dimensions, load capacity, crushing under load, true position, mass,

etc.).

Loading...

Loading...