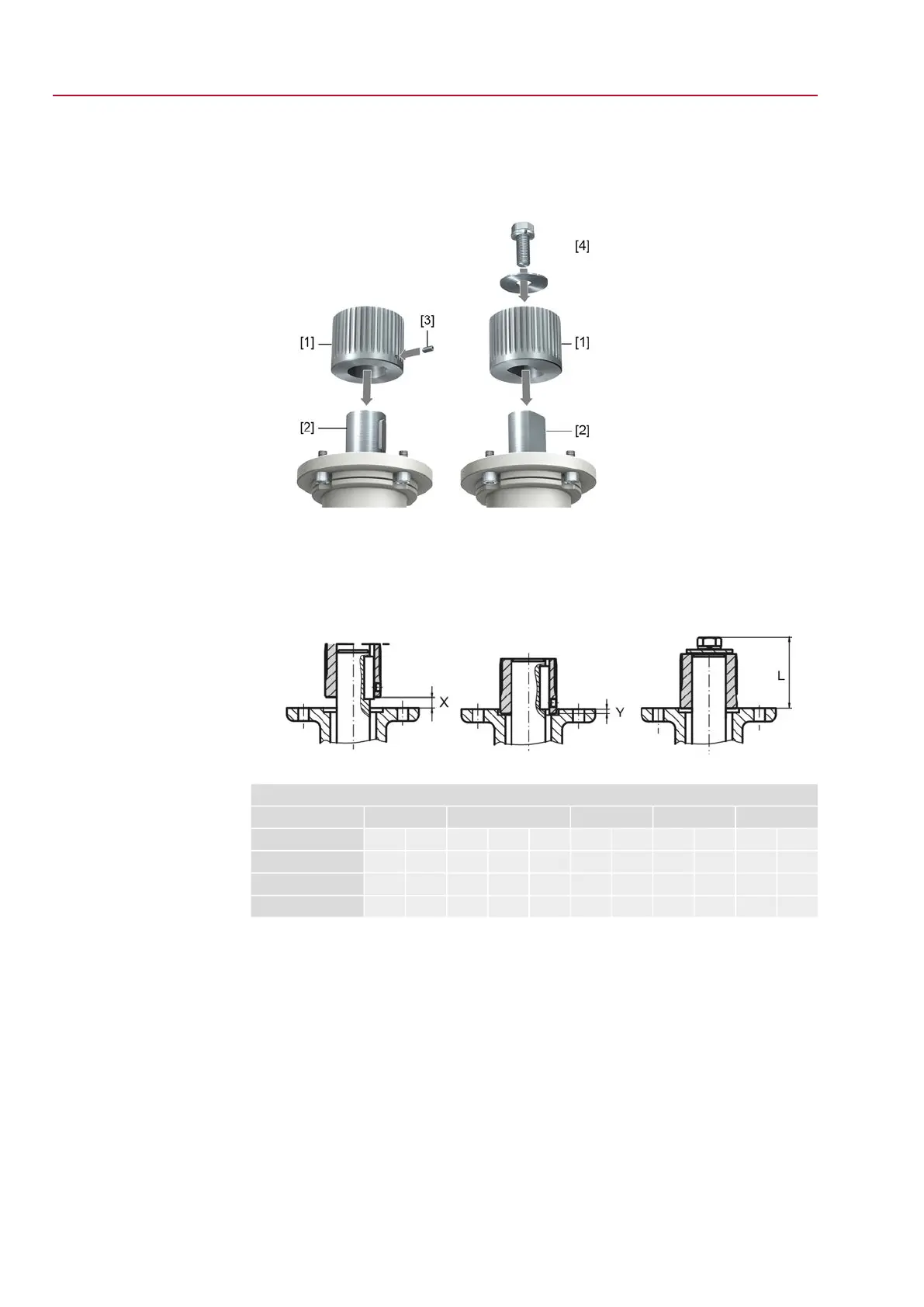

4. Place coupling [1] onto valve shaft [2] and secure against axial slipping by using

a grub screw [3] or a clamping washer and a screw with curved spring lock

washer [4].Thereby, ensure that dimensions X, Y or L are observed (refer to

figure and table <Mounting positions for coupling>).

Figure 12: Examples: Fit coupling

[1] Coupling

[2] Valve shaft

[3] Grub screw

[4] Clamping washer and screw with curved spring lock washer

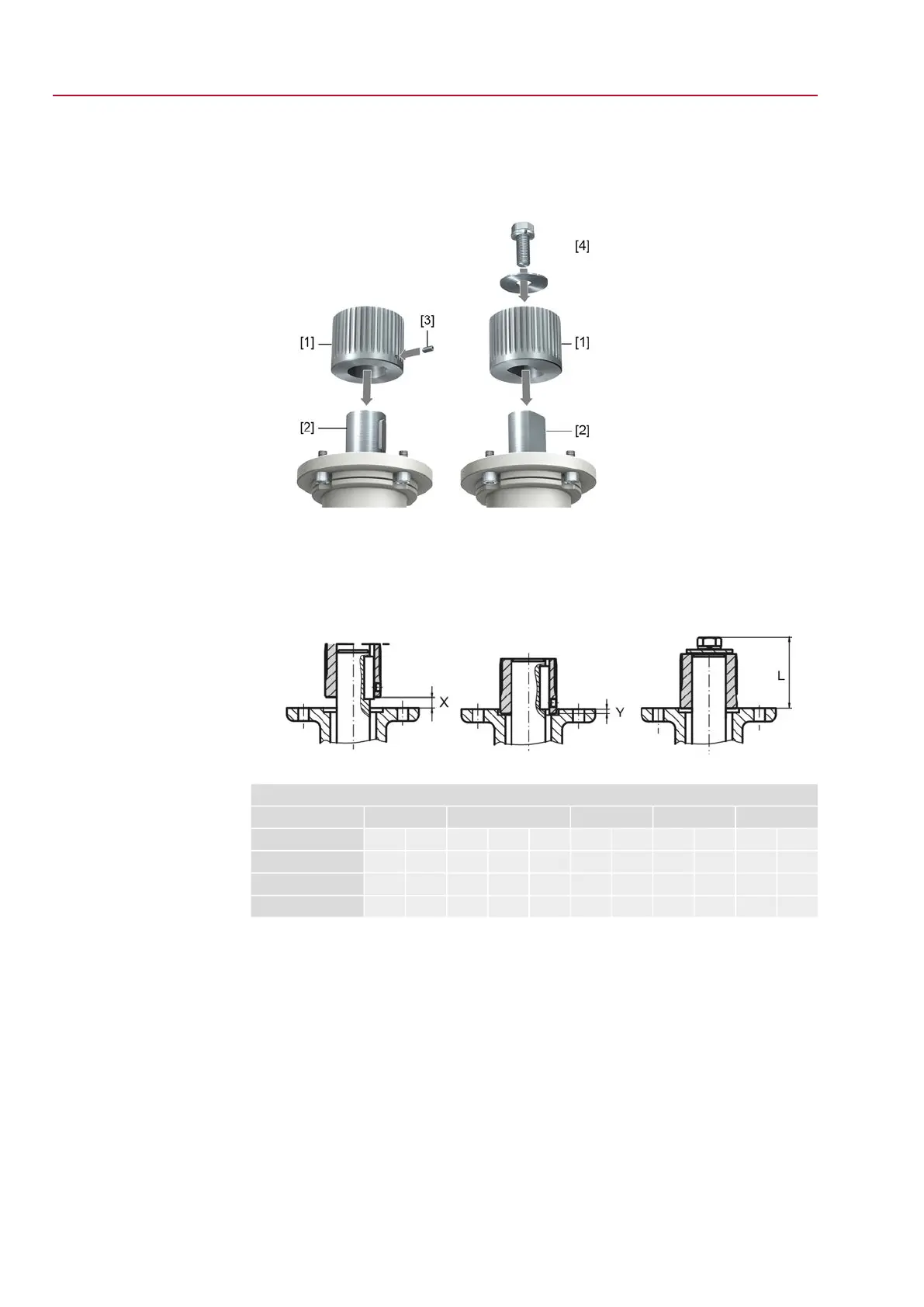

Figure 13: Mounting positions for coupling

Table 8:

Mounting position of the coupling within fitting dimensions according to AUMA definition

SQ 14.2SQ 12.2SQ 10.2SQ 07.2SQ 05.2Dimensions [mm]

F16F14F14F12F12F10F10F07F05F07F05EN ISO 5211

88554433333X max.

101010105522222Y max.

125751016182506640404040L max.

5. Apply non-acidic grease at splines of coupling (e.g. Gleitmo by Fuchs).

18

SQ 05.2 – SQ 14.2/SQR 05.2 – SQR 14.2 Control unit: electronic (MWG)

Assembly AC 01.2 Non-Intrusive

Loading...

Loading...