9. Commissioning

9.1. End stops in part-turn actuator

The internal end stops limit the swing angle.They protect the valve in the event of

limit switching failure.

End stop setting is generally performed by the valve manufacturer prior to installing

the valve into the pipework.

Exposed, rotating parts (discs/balls) at the valve!

Pinching and damage by valve or actuator.

→

End stops should be set by suitably qualified personnel only.

→

Never completely remove the setting screws [2] and [4] to avoid grease leakage.

→

Observe dimension T

min.

Information

●

The swing angle set in the factory is indicated on the name plate:

●

The setting sequence depends on the valve:

- Recommendation for butterfly valves: Set end stop CLOSED first.

- Recommendation for ball valves: Set end stop OPEN first.

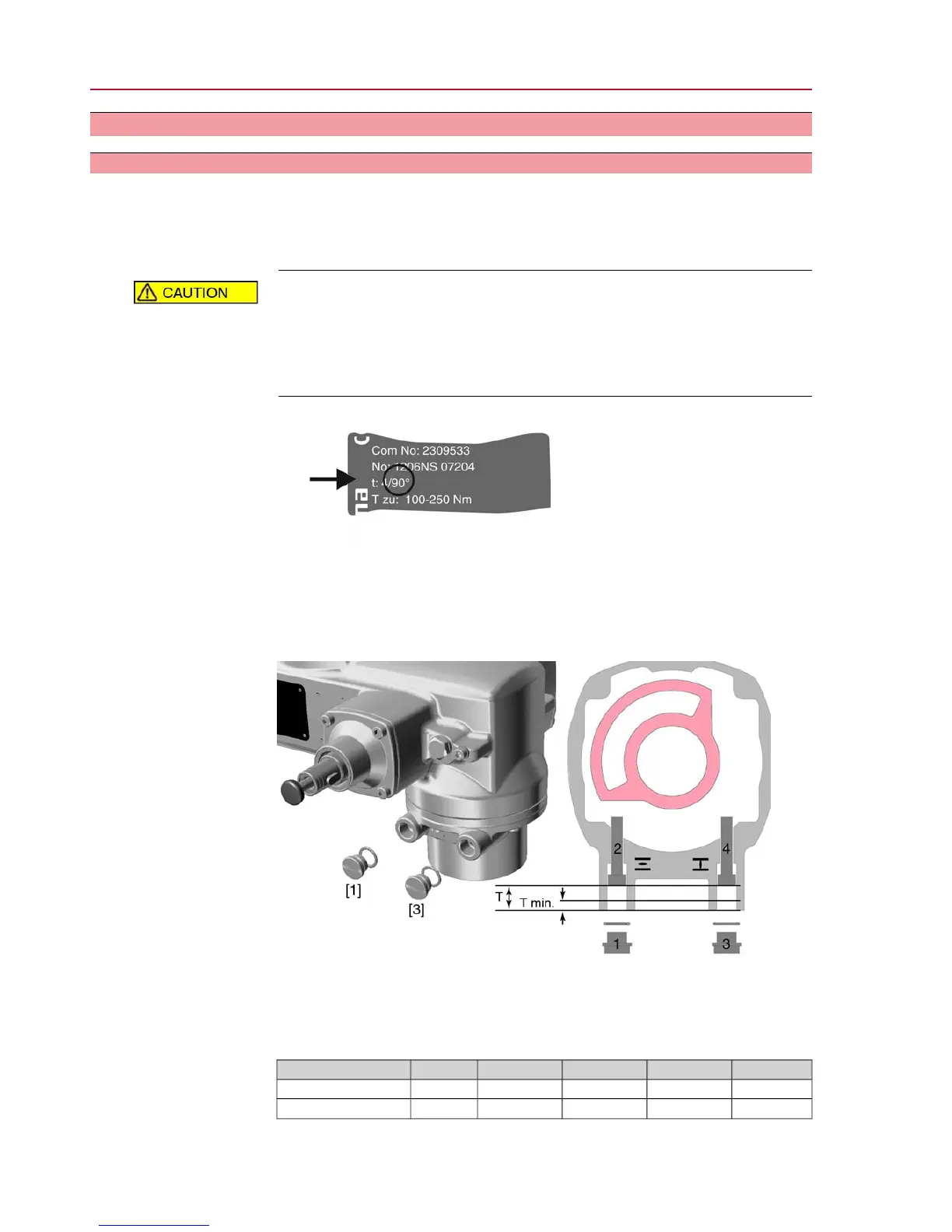

Figure 16: End stop

[1] Screw plug for end stop OPEN

[2] Setting screw for end stop OPEN

[3] Screw plug for end stop CLOSED

[4] Setting screw for end stop CLOSED

14.212.210.207.205.2Dimensions/sizes

2323201717T (for 90°)

1213121111T

min.

22

SQ 05.2 – SQ 14.2/SQR 05.2 – SQR 14.2

Commissioning

Loading...

Loading...