4

• Apply a thin film of non-acid grease (e.g., Vaseline) to sealing faces.

• Place cover and fasten the 4 bolts. Tighten diagonally.

CAUTION: NEMA 7 enclosures require that a conduit seal be placed as close as practicable to the

conduit entries at the actuator.

6. TEST RUN (Figure E)

Remove cover to the control unit compartment (15.0) and, if provided, the MDPI disc (156.0).

• Bring the valve manually to an intermediate position.

• Check phase rotation.

• Run the actuator briefly in the open direction. If the direction of rotation is incorrect, switch off

immediately and rewire motor connections U1 and W1.

• The red test knobs on the control unit provide a way to manually operate the limit and torque

switches.

While running the actuator in the open direction, turn the red test knob OPEN toward the DOL

arrow.

♦ If the motor stops, the control circuit is correct.

♦ If the motor does not stop, turn off the motor power immediately. Check control circuit and

correct wiring.

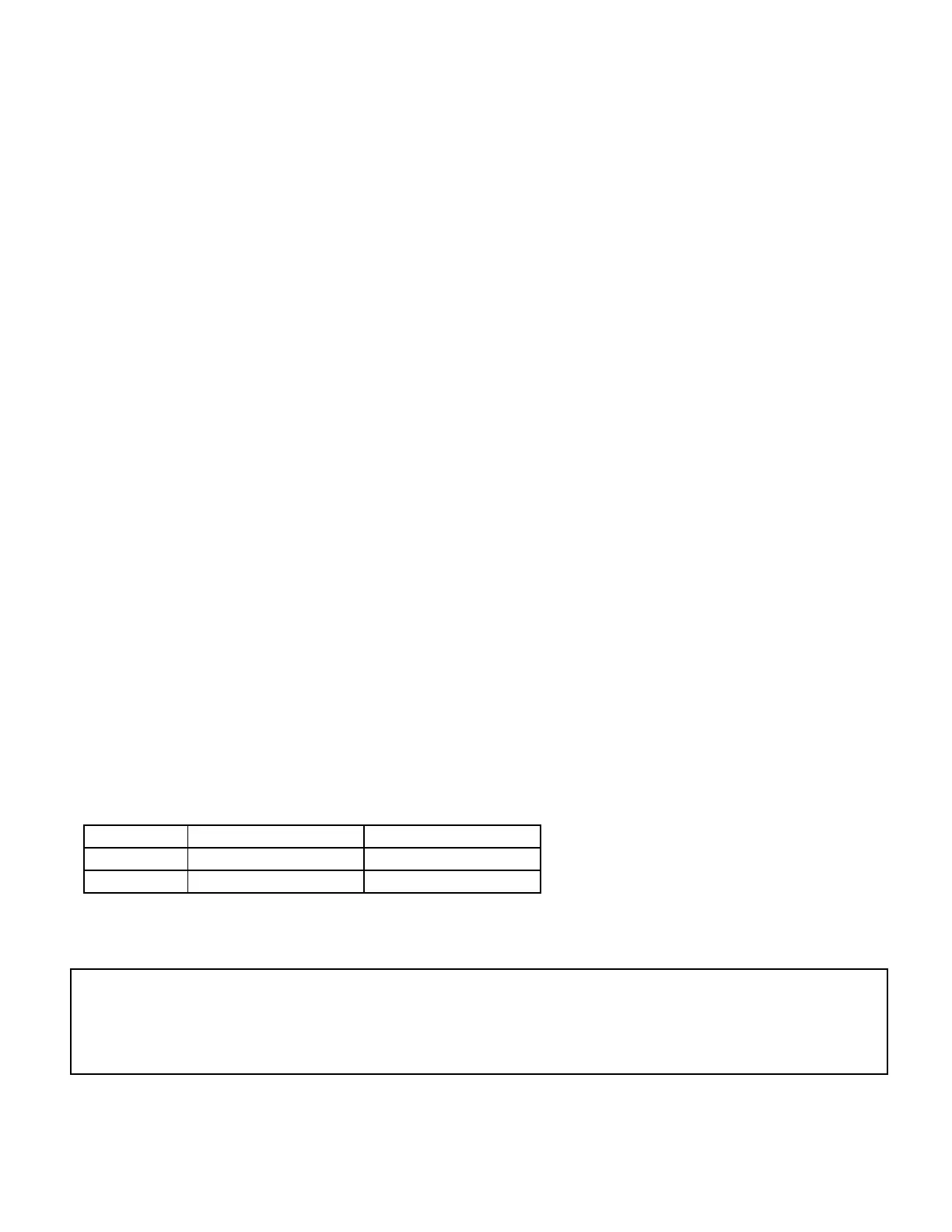

Operating Direction for Test Knobs

Torque Switch Limit Switch

open DOL Arrow WOL Arrow

close DSR Arrow WSR Arrow

• Determine overrun in both directions (overrun is turns/travel from switching off until the actuator

movement stops.

The convention of “clockwise-to-close” has been used throughout this manual. A “clockwise-to-

open” valve or damper configuration represents a reversal of limit and torque switch position

(black area

of face plate of the control unit represents open and white area represents closed.)

Loading...

Loading...