9. Commissioning (basic settings)

1. Set selector switch to position 0 (OFF).

Information: The selector switch is not a mains switch.When positioned to 0

(OFF), the actuator cannot be operated.The controls' power supply is

maintained.

2. Switch on the power supply.

Information:Please consider the heat-up time for ambient temperatures below

–20 °C.

3. Perform basic settings.

9.1 End stops in part-turn actuator

The internal end stops limit the swing angle.They protect the valve in the event of

limit switching failure.

End stop setting is generally performed by the valve manufacturer prior to installing

the valve into the pipework.

Exposed, rotating parts (discs/balls) at the valve!

Pinching and damage by valve or actuator.

→

End stops may be set by suitably qualified personnel only.

→

Set end stops to ensure that they are NOT reached during normal operation.

Information The setting sequence depends on the valve:

●

Recommendations for butterfly valves: Set end position CLOSED first.

●

Recommendations for ball valves: Set end position OPEN first.

Information When leaving the factory (without valve), the screws [1] are not fastened, i.e. the

end stops must be set. If the actuator is mounted onto the valve with the screws [1]

fastened, the valve manufacturer has already performed the end stop setting. In this

case, the end stops must only be checked (use the handwheel to drive valve into

end positions).

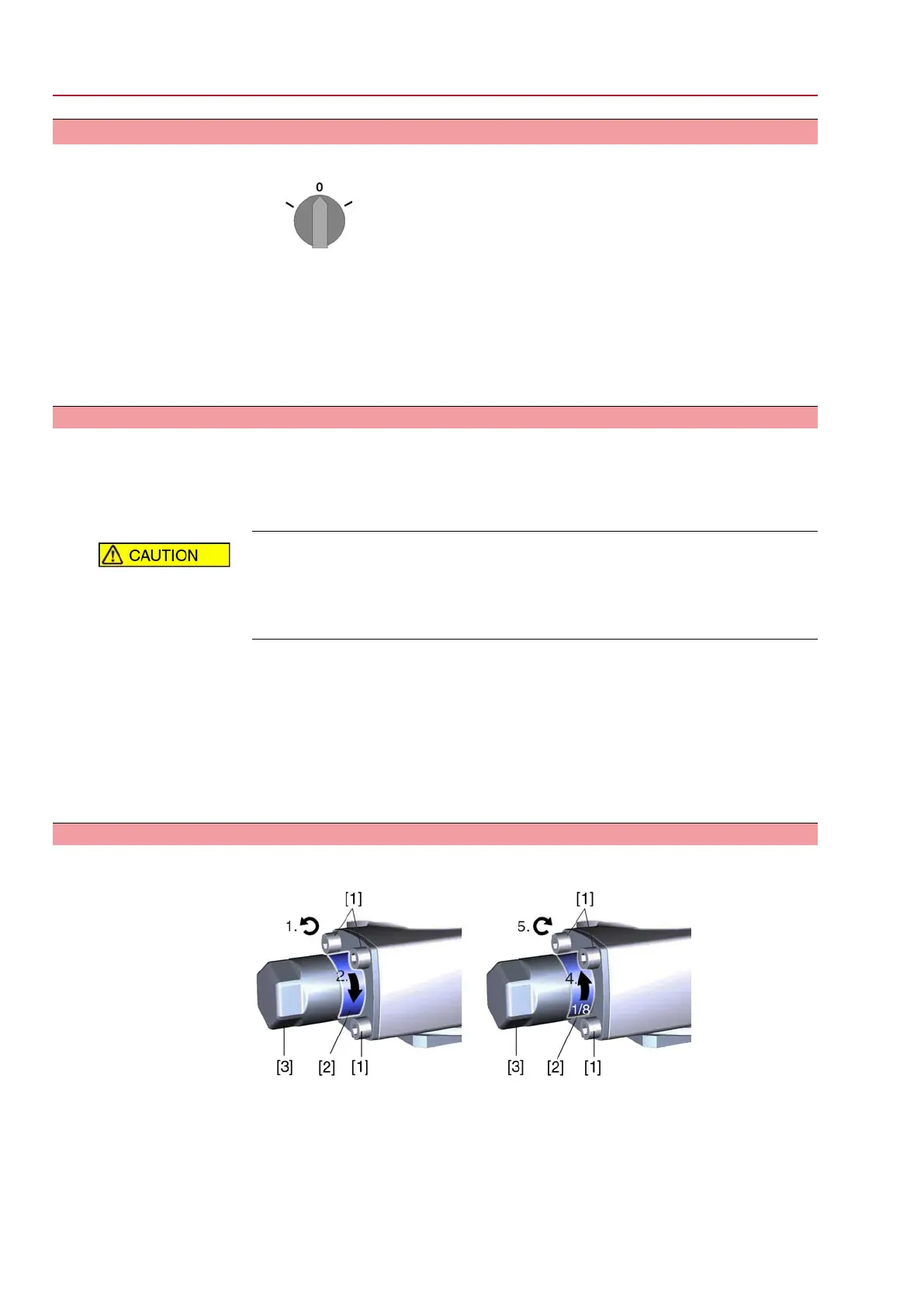

9.1.1 End stop CLOSED: set

Figure 63: End stop

[1] Screws

[2] End stop nut

[3] Protective cap

1. If the four screws [1] are fastened: Unfasten the screws [1] with approx. 3 turns.

44

SGExC 05.1 – SGExC 12.1 Control unit: electromechanic

Commissioning (basic settings) ACExC 01.2 Intrusive Modbus RTU

Loading...

Loading...