6.3.2. Cable connection

Table 17:

Terminal cross sections and tightening torques

Connection typeTerminal cross sectionsDesignation

Screw-type terminals

Tightening torque =

1.2 – 1.5 Nm

Flexible or solid:

0.25 – 10.0 mm

2

(for one wire per terminal)

Flexible:

2 x 0.25 – 4 mm

2

(for two wires per terminal)

Power contacts

(U1, V1, W1, U2, V2, W2)

PE connection

Spring clamp terminalsFlexible or solid:

0.25 – 2.5 mm

2

(for one wire per terminal)

2 x 0.25 – 0.75 mm

2

(for two wires per termin-

al)

Control contacts

(1 to 36, 37 to 50)

Ring lug/U-bracket

Tightening torque = 3 – 4

Nm

2 x M6 for cables with M6 ring lug or with U-

bracket for up to two wires with

1.5 mm

2

– 10 mm

2

Protective earth connection

within frame (customer connec-

tion)

Procedure

1. Remove cable sheathing in a length of 250 – 300 mm.

2. Insert the wires into the cable glands.

3. Fasten cable glands with the specified torque to ensure required enclosure

protection.

Information: For shielded cables: Link the cable shield end via the cable gland

to the housing (earthing).

4. Strip wires:

4.1 Remove wire sheathing of control cables (1...50) in a length of approx. 10

mm

4.2 Remove wire sheathing of motor cables (U, V, W) in a length of approx.

12 mm

5. Connect cables according to order-related wiring diagram.

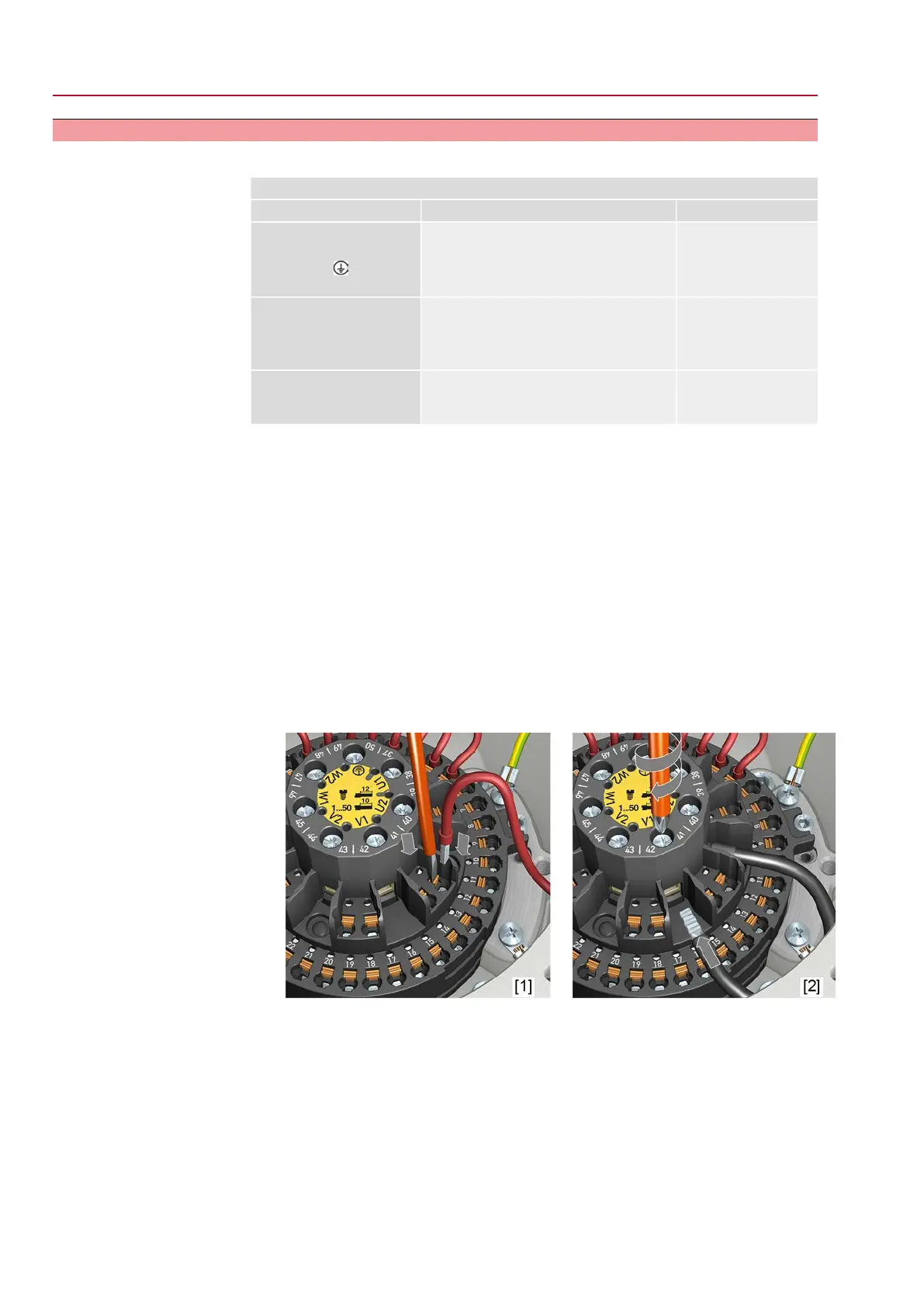

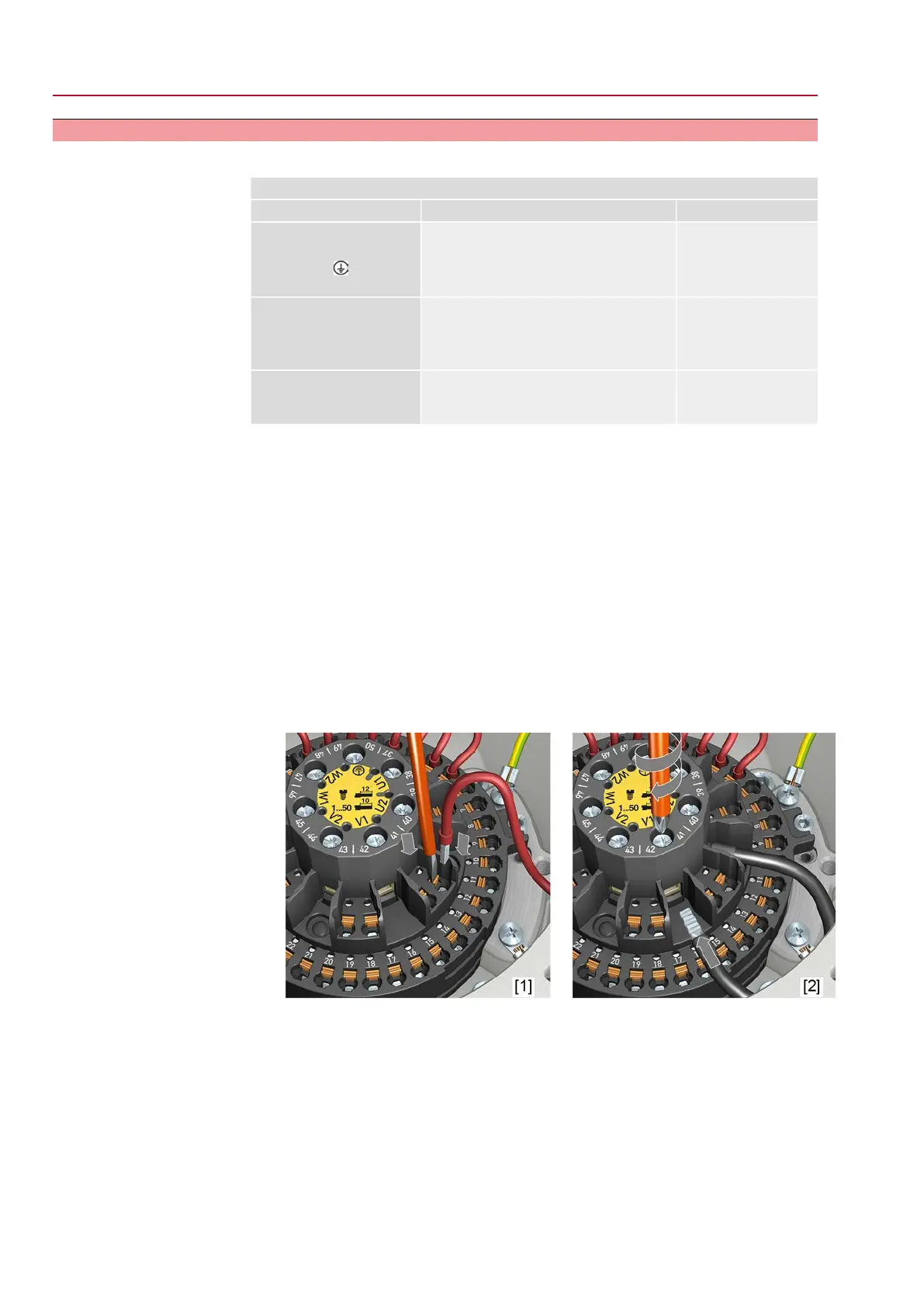

Figure 21: Connect cables to terminal carrier

[1] Fitting control cables into spring clamp terminals

[2] Tightening power terminals

Information

For service purposes, each spring clamp terminal is equipped with a test contact

located above the numbering.

Information

For flexible cables: for screw-type terminals, use wire end sleeves according to DIN

46228. For spring clamp terminals, connection is possible without wire end sleeves.

28

SQEx 05.2 – SQEx 14.2/SQREx 05.2 – SQREx 14.2 Control unit: electronic (MWG)

Electrical connection ACExC 01.2 Non-Intrusive Profibus DP

Loading...

Loading...