OM-270 231 Page 17

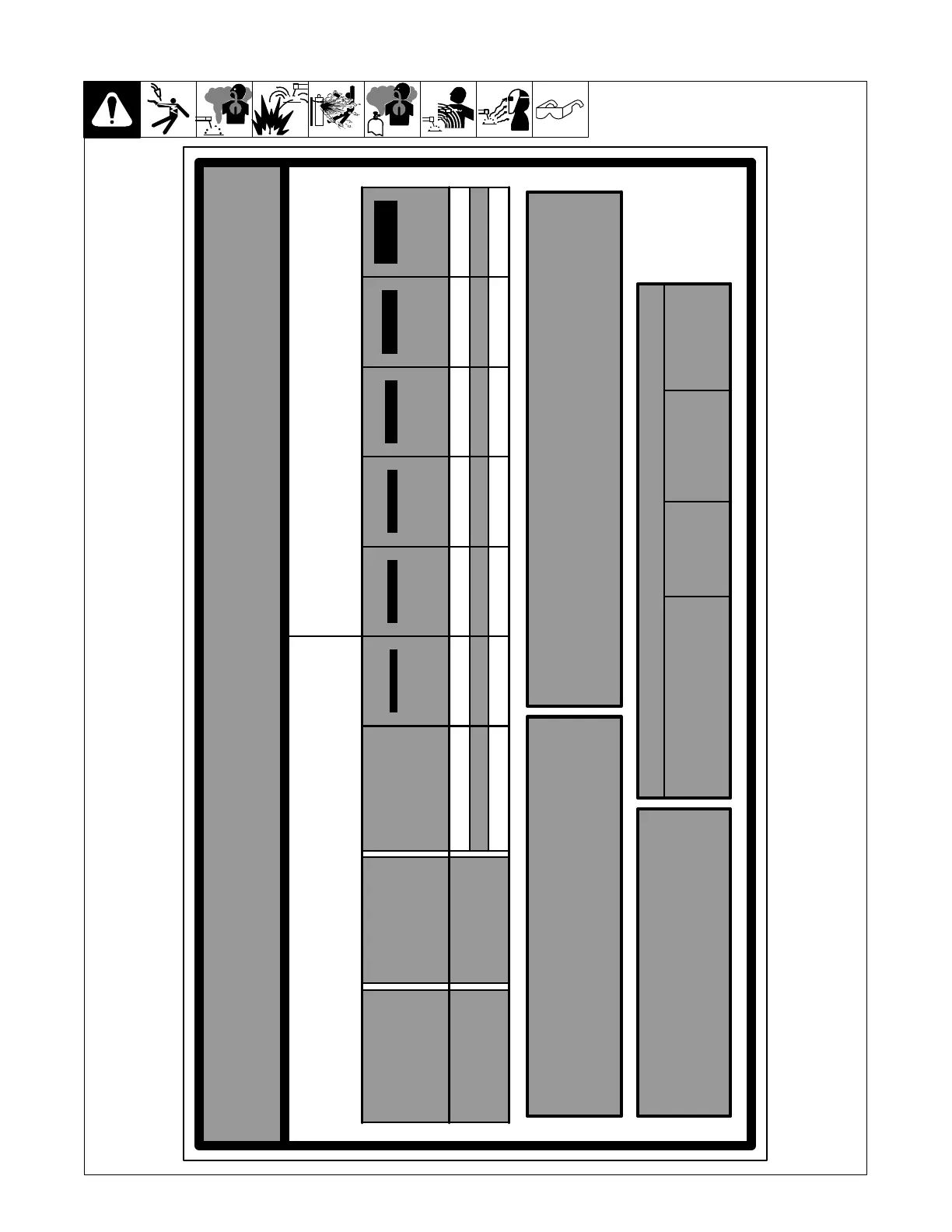

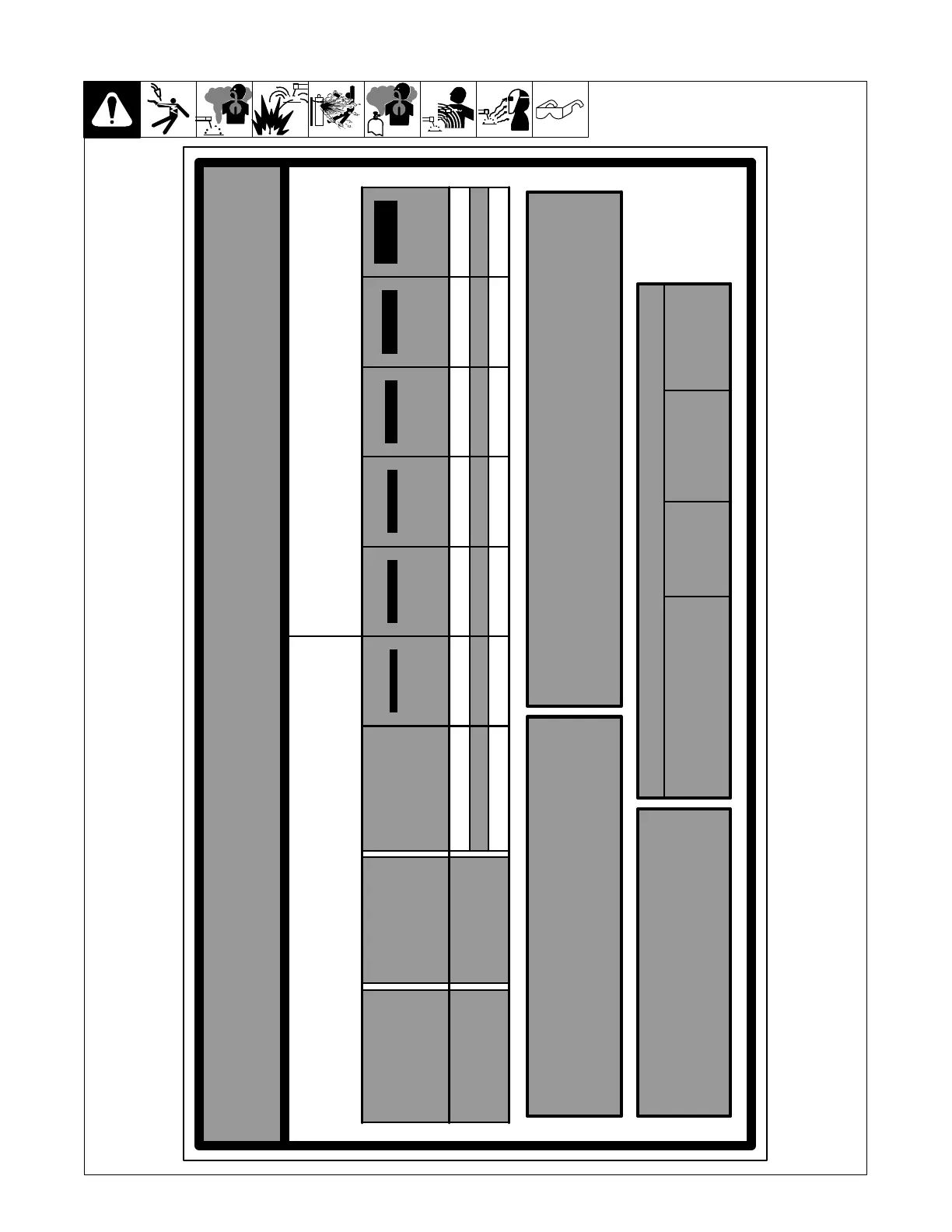

6-3. Weld Parameter Chart

Welding Guide for 115 Volt Wire Welding Package

Settings are approximate. Adjust as required.

Thicker materials can be welded using proper

technique, wire joint preparation, and multiple passes.

Match contact tip to diameter of wire being used.

Match feedroll groove to diameter of wire being used.

Adjust tension knob per instructions in the manual.

Wire Feed Setting listed is a starting value only − Wire Feed setting can

be fine−tuned while welding. Wire Feed also depends on other variables

such as stick out, travel speed, weld angle, cleanliness of metal, etc.

Recommended Voltage and Wire Feed Settings for

Thickness of Metal Being Welded. Number on Left of Slash is

Voltage Setting / Number on Right of Slash is Wire Feed Setting.

Wire Type

Flux Core

E71T−11

Material

Being

Welded

Diameter

of Wire

Being Used

.030” (0.8 mm)

.035” (0.9 mm)

4 / 60

4 / 45

1 / 25

1 / 10

4 / 50

4 / 35

18 gauge

(1.2 mm)

2 / 25

2 / 20

16 gauge

(1.6 mm)

3 / 30

3 / 30

12 gauge

(2.5 mm)

1/8 inch

(3.2 mm)

3/16 inch

(4.8 mm)

Steel

BEFORE OPERATING: NOTE:

2 / 35

2 / 25

14 gauge

(2.1 mm)

CAUTION!

Do not change Voltage Switch

Knob position while welding.

270659−A

Contact Tips

.030” (0.8 mm) − 770177

.035” (0.9 mm) − 770180

REPLACEMENT CONSUMABLES

Nozzle Tip Adapter Drive Roll

770487 770402 212379R

Loading...

Loading...