3

unpacking

The Snackshop 113 is assembled and packed so that a mini-

mum amount of time is necessary for preparation to install it on

location. The following steps are recommended to insure cor-

rect unpacking.

1. Shipping Damage: Thoroughly inspect the exterior of the

carton for damage which may have occurred during ship-

ment. Report any damage to delivering carrier and follow

their instructions.

NOTE: Machines with refrigeration units delivered on

their sides should be stood upright for 24 hours before

the machine is plugged into an outlet.

2. Remove staples from lower edge and those at top of carton,

and slit carton vertically at the taped corner. Open and

remove carton. Remove the remainder of the packing mate-

rial. On machines shipped with lock in place, the keys are

located in the coin return cup.

3. Remove Vendor With A Fork Lift Truck: Remove the car-

ton from the vendor. Open the door on the vendor and

remove the hold down bracket at the front center of the cab-

inet base and lose the vendor door. From the front of the

vendor tip the vendor backward and run forks under the cab-

inet.

4. Removing Vendor Without A Fork Lift Truck: Remove the

carton from the vendor. Remove 1/4 “ piece of plywood

located just behind the front legs, then open the door on the

vendor and remove the hold down bracket at the front center

of the cabinet base and close vendor door. From the front of

the vendor tip the vendor back far enough to clear the wood

strip across the front of the base. Slide vendor toward the back

until the back legs are off the base and pull base out.

NOTE: Because the weight concentration is toward the

back of the cabinet trucking and lifting should be done

from the back. CAUTION should be taken when trucking

from side.

5. On machines with lock in place, unlock, and turn handle to

open door. When no lock is furnished, remove tape and turn

handle. Swing door it its full open position.

6. Remove all packing tape and paper from various areas of

machine and the shipping strap.

7. Warranty: The warranty card is attached to the cover of

this manual. It must be filled out in full and mailed at

once to insure coverage.

8. IMPORTANT: A set of anchoring brackets are sent with

each machine. The kit is located in the bottom of the

machine complete with instructions. It is recommended that

this kit be installed to prevent shifting of the machine.

Kit, Part #660438

installation

1. GENERAL: In some locations, due to the size of this

machine it is not possible to move the fully assembled

machine through doors or narrow hallways. For such loca-

tions the door of this vendor can be removed, thus reducing

the clearance required down to 32 inches.

DOOR REMOVAL: To remove the door, swing door to 90

degrees. Remove bolt and washer on door end of door stop.

Unplug the light harness from the main interlock box. The

upper hinge is secured to the cabinet by one bolt extending

through the hinge from the inside of the cabinet.Remove the

bolt with a 1/2 socket. Pull the door forward, the top hinge

plate will slide out of its guide, freeing the door. Lift the door

off of the lower hinge. Remove the left side panel extension

which is held on by six screws. Remove the cabinet to door

filler assembly which is held on by twelve screws. To install

the door, reverse the above procedure.

2. LEVELING THE MACHINE on location is important for the

proper function of the machine. The four leveling screws in

the legs are the means of leveling the machine. After posi-

tioning the machine, level machine in front to rear and right

to left directions. After leveling, turn front right (lock side) lev-

eling screw in about one-half turn to drop this corner slight-

ly to make the door easier to close and lock.

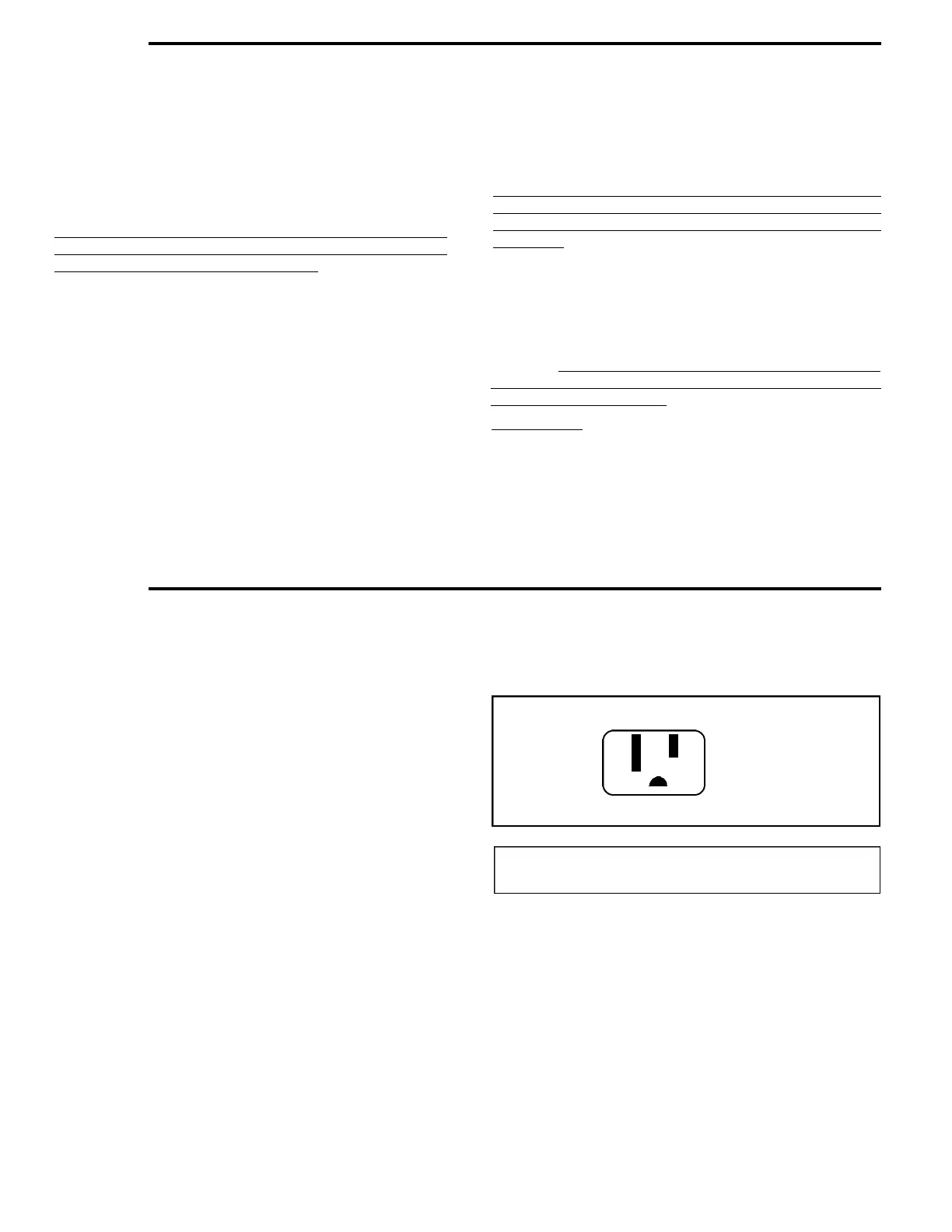

3. VOLTAGE AND POLARITY CHECK. It is important that this

machine is hooked up to the proper voltage and polarity.

Using a voltmeter, perform the following checks from the

illustration below.

(A)

(B)

(C)

(A) to (B) = 117 VAC (+-10%)

(A) to (C) = Less than 1 VAC

(B) to (C) = 117 VAC (+-10%)

A. C. HOT (B)

A. C. NEUT (A)

EARTH (C)

GROUND

NOTE: Should the readings be different from above,

have a certified electrician correct the problem.

Loading...

Loading...