1-2

Chapter 1. OVERVIEW

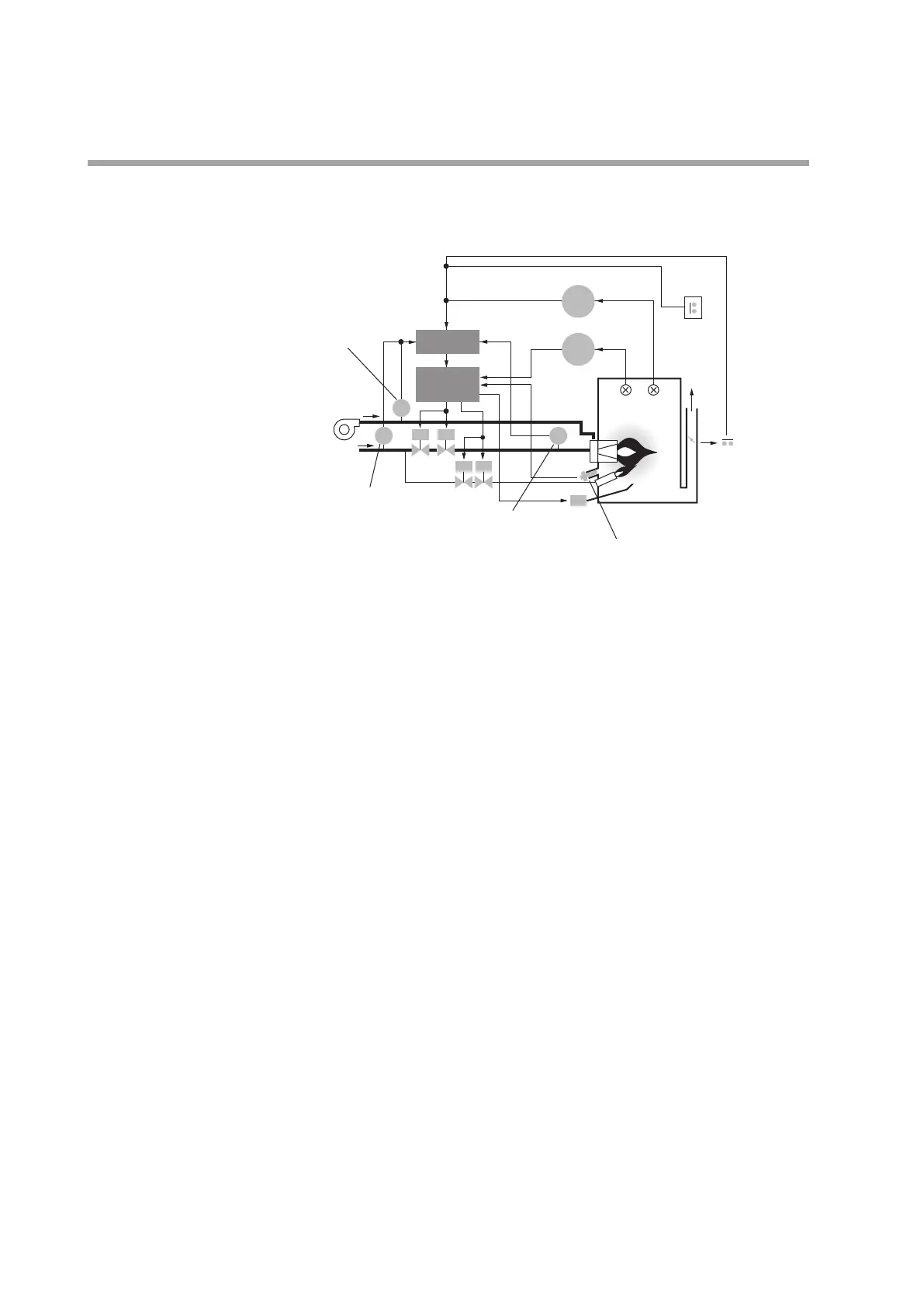

System structure

This device is used to control the flame of combustion equipment, and is used in a

system like the one shown below.

interlock

Gas pressure lower limit

interlock

Gas pressure upper limit

interlock

Ignition

transformer

Air

Gas

MV1 MV2

PV1 PV2

T/C T/C

L

L

H

UV

Controller

Overtemperature limit

Vibration

detection limit

Combustion

chamber

Combustion

equipment

interlock

Flue

duct

Burner controller

BC

(AUR450C)

Limit/Interlock

PS

PS

IG

PS

TIC

TIA

Flame

Exhaust

gas

Vibration

detector

Safety assurance functions

This device performs functions that are vital for burner operation and flame

monitoring.

•

Combustion monitoring and safety shutdown

•

Detects burner flame failure and shuts down the fuel supply immediately.

•

In case of ignition failure or flame failure, shut down each value ignition trans-

former in a predetermined sequence.

•

Startup, operation and shutdown of combustion equipment

•

Operates each value ignition transformer in a predetermined order, with preset

timing.

•

Fixed ignition timing

To ensure safety, the ignition circuit is so designed that ignition cannot continue

in excess of the specified time, even if part of the ignition circuit fails.

•

Safe startup

•

Checks flame detector and flame circuit for internal failure before every startup.

•

If failure is detected, prevents burner startup.

•

Checks for false flame detection or false discharge of the tube unit, failure of

the ignition circuit, and failure of the alarm circuit.

•

Flame safeguard control in compliance with safety standards

This controller’s design is based on North American and European safety stan-

dards, and it is certified to meet them. This device can be used with combustion

safety equipment in Europe and North America.

•

Dynamic self-checking

Checks continuously for sensor failure of the AUD300C/500C and for failure of

the flame detection circuit, even during the RUN stage of operation. If failure is

detected, fuel supply shutdown and lockout are immediately carried out.

•

Protection against part failure

Failure Mode Effect Analysis (FMEA) has been done for all parts. Even if a part

failure occurs, safety will be maintained, and dangerous conditions such as the

following will not occur:

•

Out-of-order ignition sequence.

•

Dangerous sequence timing (longer ignition time)

Loading...

Loading...