4-16

B. Revers action models

(1) Secure the bottom diaphragm case with the four bolts to the yoke. At the same time, set

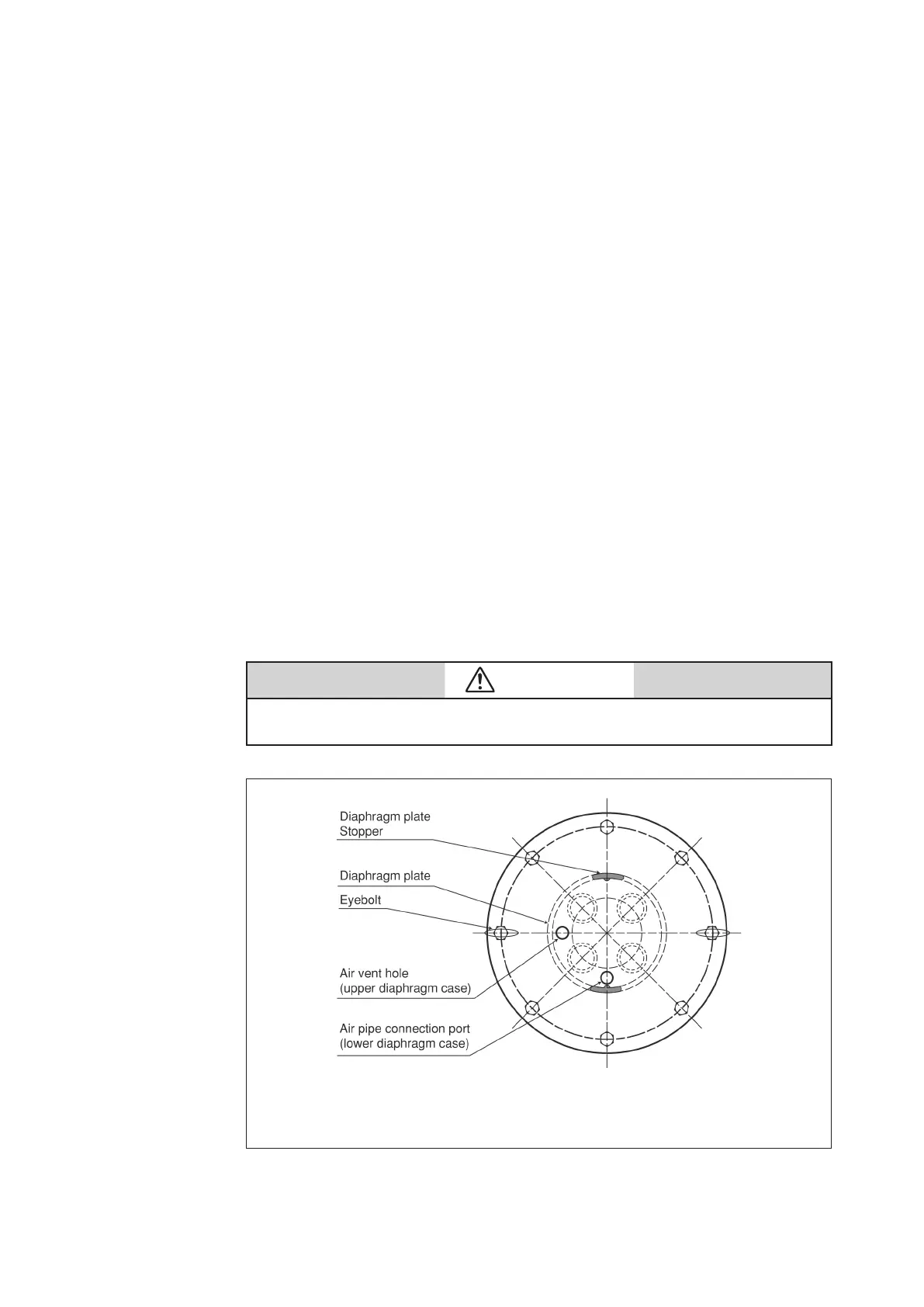

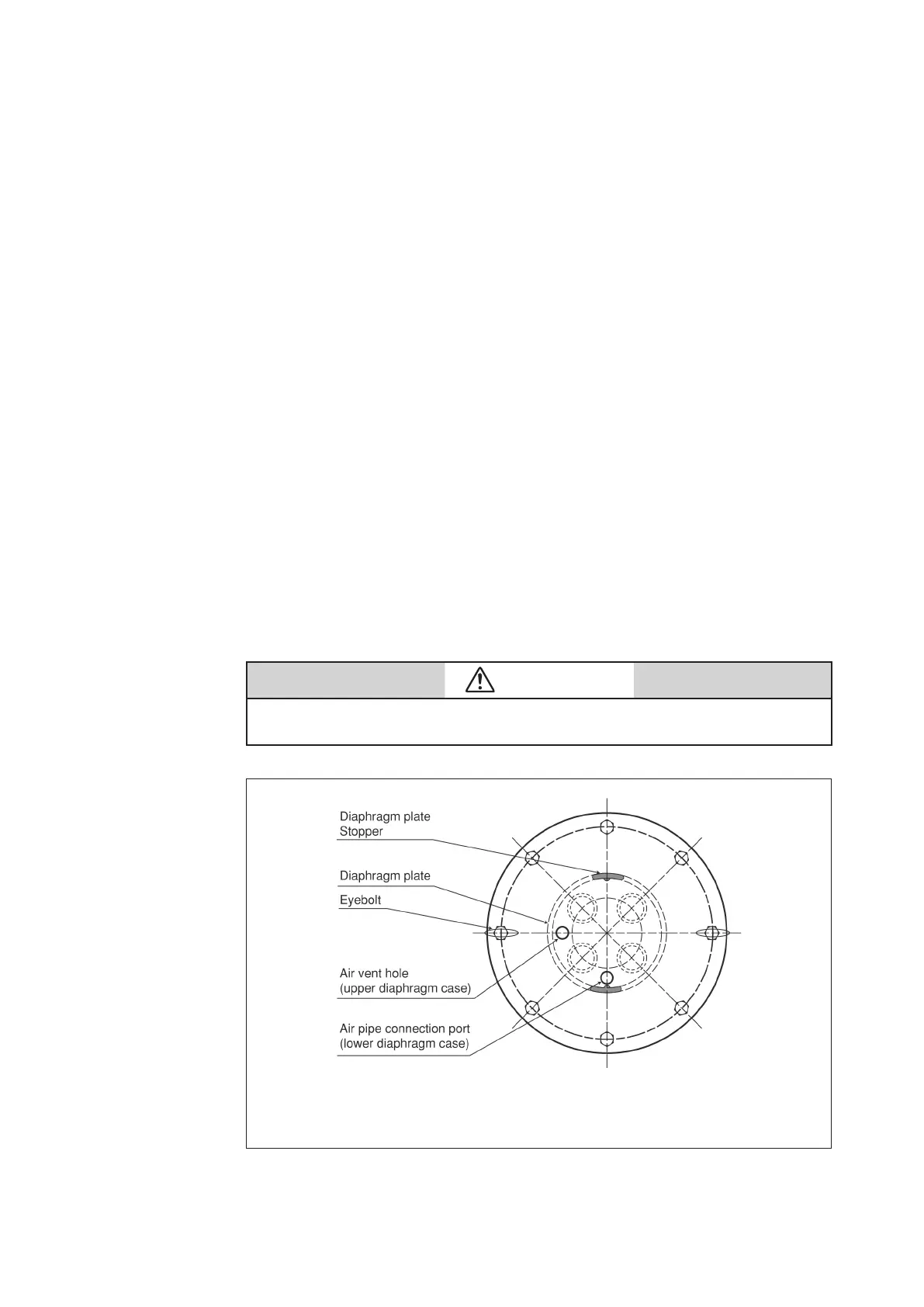

the air pipe connection port in the location shown in the Figure 4-11.

(2) Insert the actuator rod (with diaphragm connected) into the bushing. Be careful to

prevent the bushing 's inside surface or dust seal from being damaged by the threaded

section of the rod. If possible, cover the threaded section with adhesive tape.

(3) Rotate the actuator rod, locating its diaphragm plate stopper as shown in Figure 4-11.

(4) Fasten the spring plate and install the springs onto the spring plate. (see Figure 4-11).

(5) Place the top diaphragm case and secure it with the pair of eyebolts.

Note: Set the air vent hole to the location shown in Figure 4-11. Uniformly and alternately

tighten the eyebolts. The initial setting of the springs is completed by tightening

these eyebolts.

(6) Clamp the diaphragm case with clamping bolts.

(7) Install the stem connector.

(8) Install the stem cap onto the air vent port.

(9) Connect the air pipe to its connection port at the bottom diaphragm case.

(10) After completing of assembly, check the following.

• Apply air pressure of 500 kPa {5 kgf/cm

2

}through the air pie connection port at the

diaphragm case, and check the diaphragm periphery for air leakage with soapy water.

• Check that the actuator operates smoothly through to its full stroke by operating the

actuator as an independent unit.

CAUTION

Install packing for the rod and dustseal in the correct direction. Refer to Figure 4-9.

Figure 4-11 Reverse Action Model

Model PSA1R Actuator

Loading...

Loading...