6-2

Chapter 6. TROUBLESHOOTING

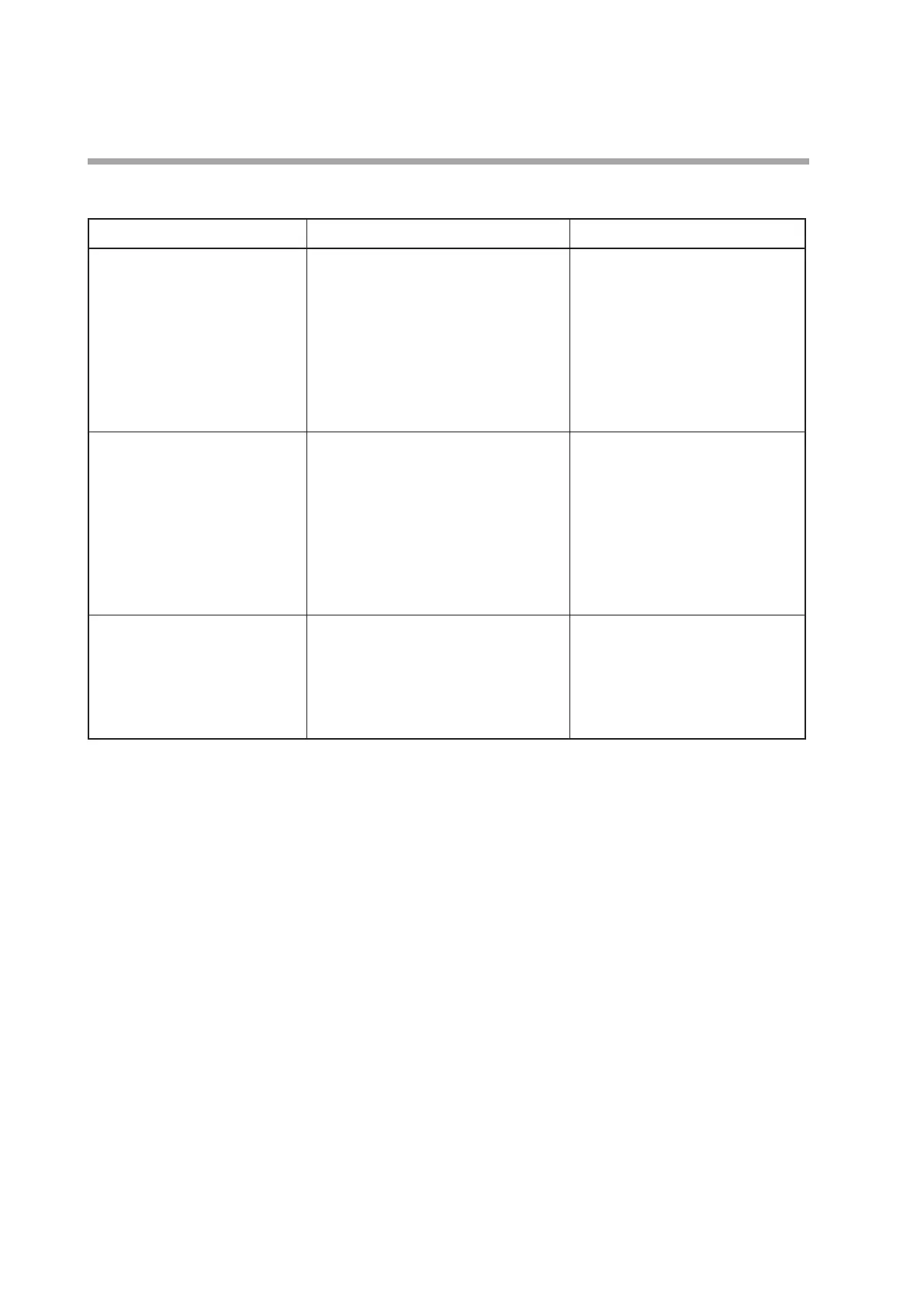

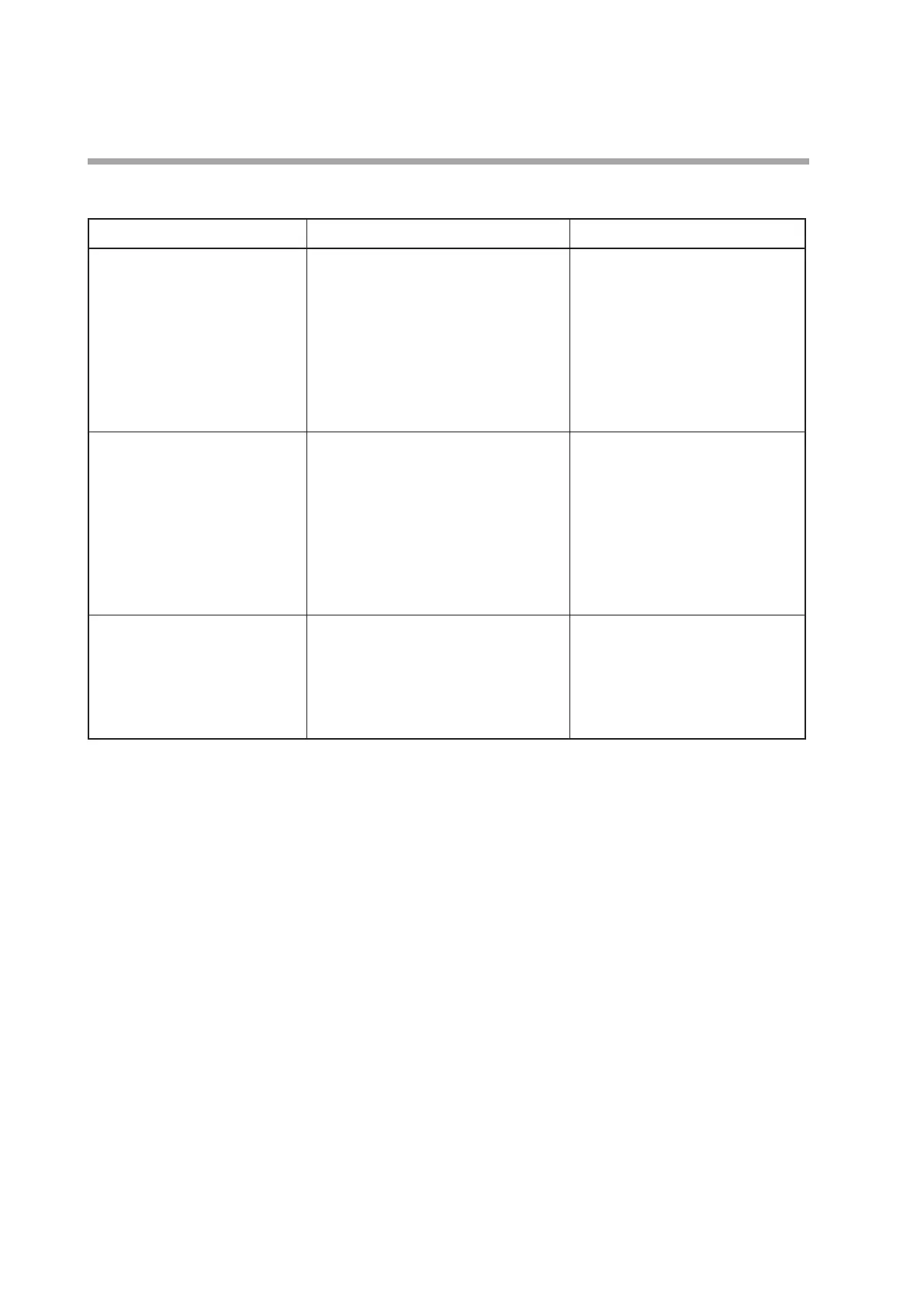

Other troubles

Error Cause Countermeasure

Flowrate display does not become

zero even in spite of an actual zero

flowrate.

(Display does not become OFF even

if the valve is fully closed.)

• Zero point shift due to the influence of

pressure.

• Gas type setup is incorrect.

• Condensation on sensor.

• Foreign object attached to sensor.

• Adjust the inlet pressure setting

(function setup C-20) with the actual

inlet pressure used, or use the PV

forced zero function (function setup

C-29).

• Adjust the gas type setting (function

setup C- 18) with the actual gas used.

• Insert a mist trap upstream.

• Request for repair service.

Flowrate does not stabilize. • Operation differential pressure range is

exceeded.

• Large inlet pressure fluctuations.

• Regulator interference.

• Large pressure loss between regulator

and this device. (Large fluctuation in inlet

pressure according to flowrate.)

• Reduce the inlet pressure.

• Install a regulator upstream.

• Change the regulator pressure setting

or apply the PV filter.

(function setup C-23)

• Change the pipe bigger diameter.

Poor accuracy • Temperature reference does not match

the reference flowmeter.

• Regulator is vibrating slightly.

• Foreign object attached to sensor.

• Adjust the temperature reference.

(It can be changed in the function

setup C- 19)

• Change the regulator pressure

setting.

• Request for repair service.

Loading...

Loading...