7-6

Chapter 7. SPECIFICATIONS

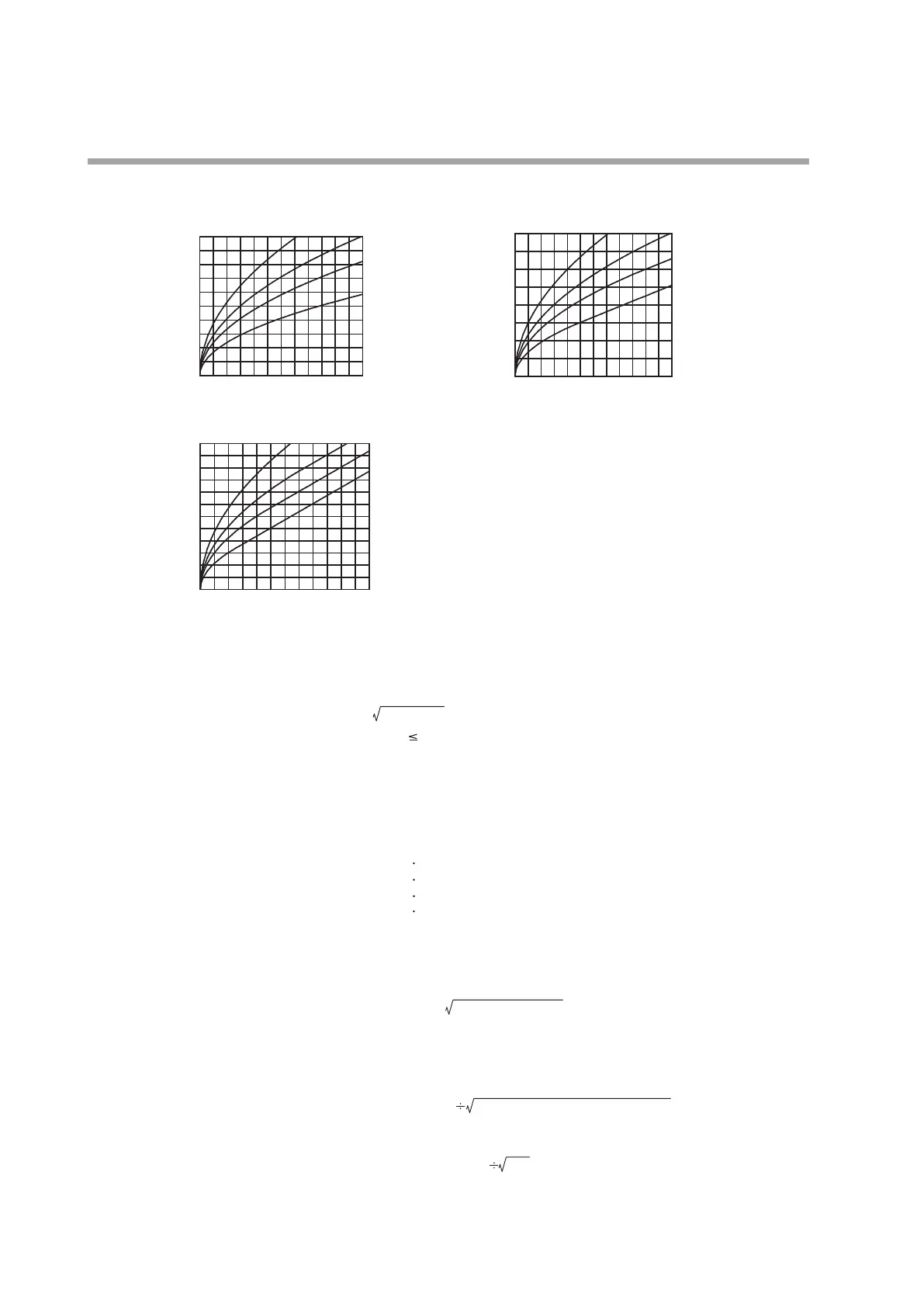

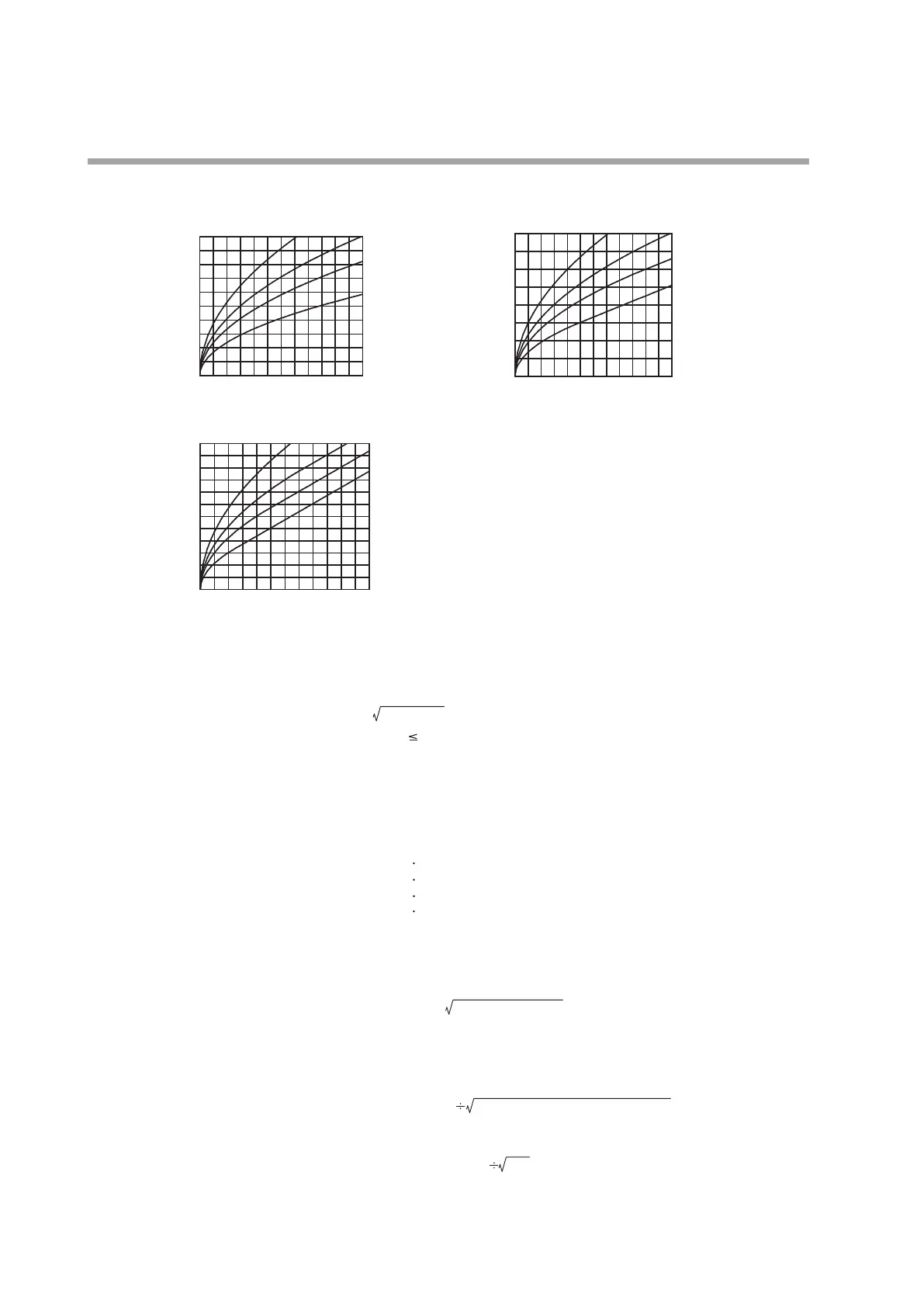

Relationship between flowrate and differential pressure with valve fully opened (in air)

Four parameter show outlet pressure.

MPC9500 MPC0002/0005

MPC0020

0

5

10

15

20

25

30

0 40 80 120 160 200 240

Flowrate [L/min(standard)]

0.0

0.2

0.4

0.6

0.8

1.0

0 10 20 30 40 50 60

Flowrate [L/min(standard)]

Dirential pressure [kPa]

Dirential pressure [kPa]

0

2

4

6

8

0 20 40 60 80 100 120

Flowrate [L/min(standard)]

150 kPa(gauge)

150 kPa(gauge)

50 kPa(gauge)

150 kPa(gauge) 50 kPa(gauge)

0 kPa(gauge)

-50 kPa(gauge)

0 kPa(gauge)

-50 kPa(gauge)

50 kPa(gauge)

0 kPa(gauge)

-50 kPa(gauge)

Dirential pressure [kPa]

• If the outlet pressure is diffrent from the values graphed on the above,

calculate the flowrate using the appropriate formula below.

(1) When P2 / P1 > 0.53,

Q=C1 (P1-P2) X P2

(2) When P2 / P1 0.53,

Q=C2 X P1

P1: Inlet absolute pressure [kPa (abs)]

P2: Outlet absolute pressure [kPa (abs)]

(Absolute pressure =gauge pressure +atmospheric pressure)

Q: Flowrate [L/min (standard)]

C1 and C2: Constant values by model

MPC 9500 : C1=0.01054, C2=0.00526

MPC 0002 : C1=0.05971, C2=0.02981

MPC 0005 : C1=0.05971, C2=0.02981

MPC 0020 : C1=0.16740, C2=0.08357

Example : When using the MPC0020 with inlet pressure = 120 kPa (gauge) and outlet pressure

= 0 kPa (gauge),

P1 = 221.3 kPa (abs), P2 = 181.3 kPa (abs)

P2 / P1 = 0.819

Q = 0.1674 X (221.3 - 181.3) X 181.3

= 14.3 [L/min (Standard)]

• When used with the gases other than air, convert the flowrate using the

following formula :

Flowrate = Flowrate in air specic gravity of gas to be controlled

Example : When using the

MPC

0020 with

CO

2, inlet pressure = 100

kPa (gauge) and outlet pressure

= 0 kPa (gauge)

16.8 L /min (standard) 1.53 = 13.6 L /min (standard)

Specific gravity standard compatible gas (air is taken as 1.0)

Argon = 1.38

Carbon dioxide (CO

2

) = 1.53

Loading...

Loading...