3 - 80

Thread cutter module

Modules

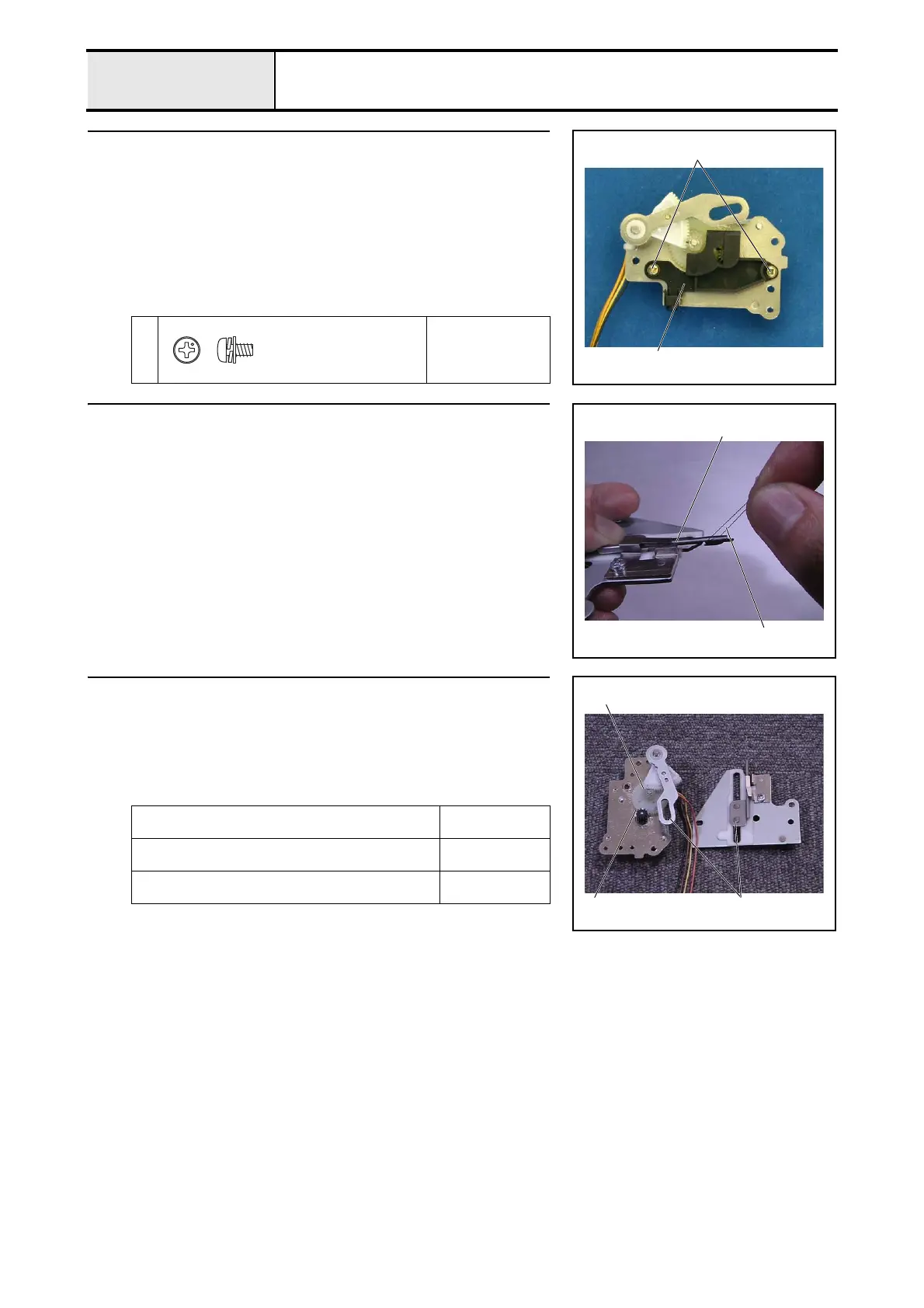

9 Sensor holder attachment

1. Attach the sensor holder 1 with the 2 screws 1.

1

Torque

0.78 – 1.18 N·m

1

1

Screw, Pan (S/P washer)

M3X6DA

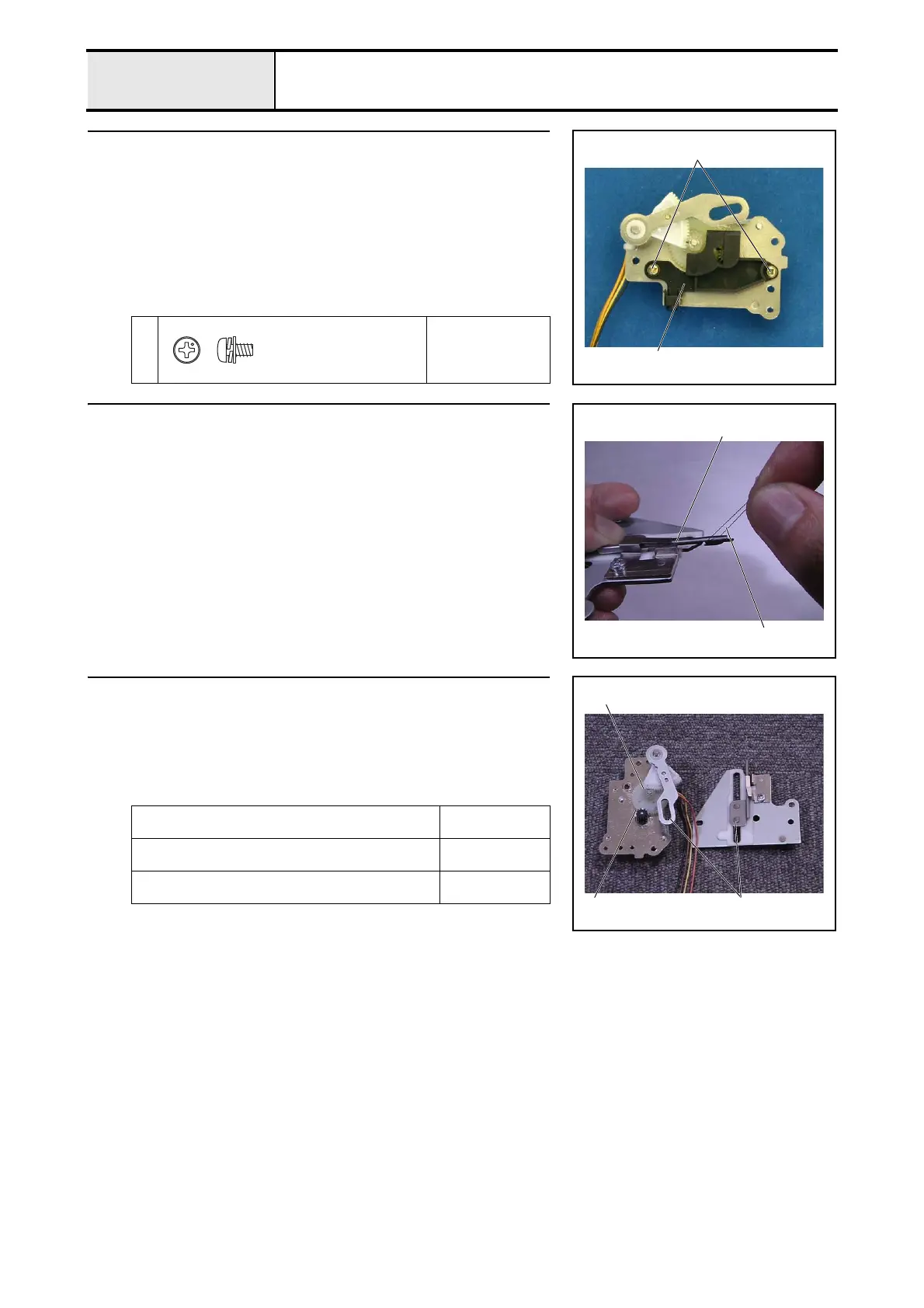

10 Thread cutter check

1. Pull the thread hook assy 1 from the thread cutter frame assy.

2. Attach Schappe Spun Sewing Thread #30 2 to the end of the thread hook

assy 1, and check that the thread is cut when the thread hook assy returns.

2

1

11 Grease applications

1. Apply a small amount of EPNOC AP(N)0 to the all of the operating

surfaces 1 of the idle gear assy. and C pulse motor gear.

2. Apply a small amount of EPNOC AP(N)0 to the all of the operating

surfaces 2 of the thread cutter lever gear and idle gear assy.

3. Apply a small amount of EPNOC AP(N)0 to the entire operating surface

3 of the thread cutter lever thread hook pin A.

Apply EPNOC AP(N)0 to the entire operating surfaces

of idle gears A and B and the CPM gear.

Small amount

XC8387***

Apply EPNOC AP(N)0 to the to the operating surfaces

of the thread cutter lever gear and idle gears A and B

Small amount

XC8387***

Apply EPNOC AP(N)0 to the operating surface of thread

hook pin A

Small amount

XC8387***

2

1 3

Loading...

Loading...