ESM-UM-02782-EN-12

INSTALLATION

• DO NOT ATTEMPT TO USE ANY METER AS A LEVER OR CROWBAR TO STRAIGHTEN A MISALIGNED METER POSITION. THIS

COULD DAMAGE THE METER.

• TO AVOID POTENTIAL PROBLEMS, CORRECT ANY IRREGULARITIES IN PIPE SPACING AND MISALIGNMENT BEFORE PLACING

THE METER INTO ITS POSITION.

• METERS MUST OPERATE IN A COMPLETELY FILLED LINE AT ALL TIMES. THE DOWNSTREAM PIPING MUST ALWAYS BE ARRANGED

TO PROVIDE SUFFICIENT BACK PRESSURE TO MAINTAIN A FULL LINE AT THE METER. BY ELIMINATING AIR IN THE LINE, AS WELL

AS SUDDEN FLOW SURGES, INACCURATE REGISTRATION AND DAMAGE TO THE METER CAN BE AVOIDED.

Pre-Installation

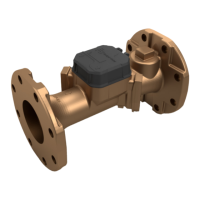

Take into account the following considerations before you begin an E-Series Ultrasonic meter installation:

• Inspect the piping around the meter for suitable conditions. The service line, valves, connections and meter must be

watertight. Repair the piping system if pipes are corroded or damaged.

• Install the meter in the pipeline in a horizontal or vertical position so that the flow arrow on the meter housing points in

the same direction as water flow. Registration should be upright and protected from damage, freezing and tampering.

• Verify meters are correctly programmed.

• Position the meter so it is accessible for installation, removal and reading.

• The line opening for the meter should match the lay length of the meter, allowing slight additional space for coupling

gaskets. The inlet and outlet sides of the meter should be axially aligned to the pipe.

• The installed meter must not be an obstacle or a hazard to the customer or interfere with public safety.

• To avoid cavitation, always install control valves downstream of the meter. Never install the meter on a pump suction side.

• Consider maximum flow rates when sizing and selecting the appropriate meter for the application.

• A minimum of 5 pipe diameters of straight, unobstructed pipe is recommended upstream of the meter.

• Do not install check valves or pressure reducing devices within 5 pipe diameters upstream of the meter.

• Only fully open gate or ball valves should be used immediately upstream of the meter. Butterfly valves must be 5 pipe

diameters or more upstream of the meter. Fully open gate, ball or butterfly valves can be used downstream.

OTE: N A partially opened gate or ball valve, or butterfly valve installed immediately upstream of the meter could

adversely affect meter accuracy.

• A service saddle (or reducing tee) should be at least 2 pipe diameters downstream of the meter outlet flange.

• Unweighted check valves should not be located closer than 3 pipe diameters downstream of the meter.

• Pump discharge should be installed at least 5 pipe diameters upstream of the meter.

• Externally weighted check valves and pressure reducing devices should be located no closer than 5 pipe diameters of

the meter.

• The meter is designed so that a strainer is not required. If installing a strainer, it is recommended that it be installed a

minimum of 5 pipe diameters upstream of the meter in order to maximize the accuracy of your measurements.

• During meter replacement, if there is already a strainer installed immediately upstream, to attain the highest accuracy

capabilities, consider moving the strainer downstream of the meter or further upstream.

• If you are using a strainer that is a size smaller than the pipe installation, 5 diameters of pipe is required in order to reduce

the effect of jetting caused by increase in flow velocity. Additional length is required if a sharp contraction or an eccentric

reducer is used, rather than a concentric, tapered reducer.

• To allow for the dampening of velocity profile distortions, elbow (90°) configurations should be installed a minimum of five

pipe diameters upstream the meter and/or downstream the meter. Where spiral flows are created by three-dimensional

elbows or rotary pumps, additional downstream distance to dampen the effect is beneficial.

Installation

Page 6 December 2021

Loading...

Loading...