8 | 32W. Baelz & Sohn GmbH & Co. · Koepffstrasse 5 · 74076 Heilbronn · Germany · www.baelz.de Seite | Page

Motorized Rotary Actuator baelz 375-E42

4. ASSEMBLY

Make sure that the specications on the nameplate correspond to those in

the order documents!

4.1 Fitting position

Do not mount rotary actuators "head down" below the valve. Allow for about 200 mm space

above the cover at the site of installation.

4.2 Assembly with the valve

Before assembly, check the rotary actuator for damage. Damaged parts should be replaced

with original spare parts. After assembly, check the rotary actuator for damage to the paint.

Touch up the paint if necessary in order to prevent corrosion.

ForgatevalvestherecommendedassemblypositionistheSHUTendposition.Forthis,

turnthecrankwheelontherotaryactuatorclockwiseuntilthemechanicalstopoftheSHUT

position is reached before assembling.

For ball valves the recommended assembly position is the OPEN end position. For this, turn

the crank wheel on the rotary actuator anticlockwise until the mechanical stop of the OPEN

position is reached before assembling.

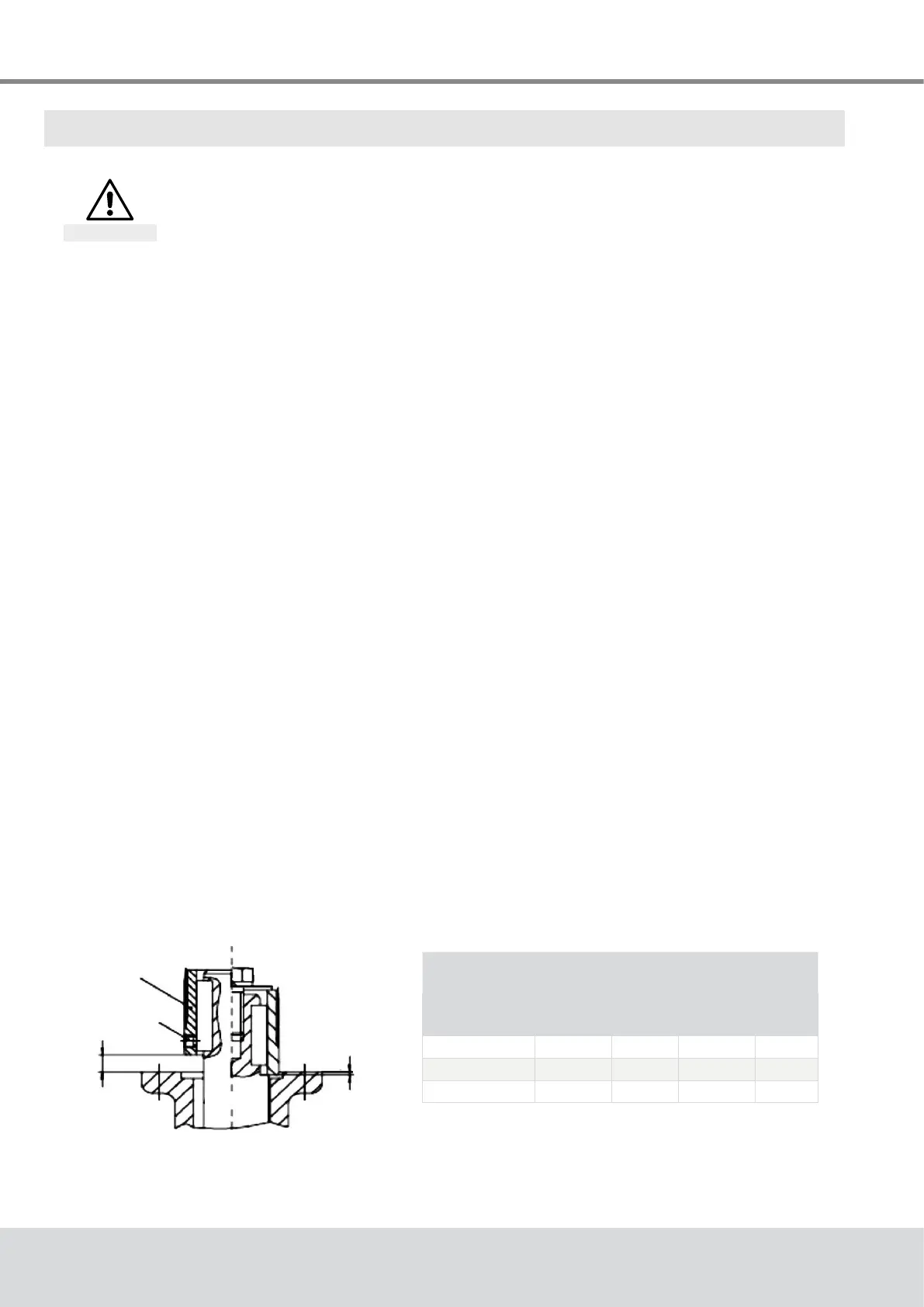

Thorouglydegreasethecontactsurfacesoftheconnectingangesoftherotaryactuator

and the valve. Lightly grease the valve shaft. Fit the coupling to the valve shaft and secure it,

keepingtothedimensionsXandY(seeFig. 2 and Table 3,below).

Lubricate gear teeth on the coupling thoroughly with acid-free grease. Fit the actuator so

thattheconnectionholesintheactuatorandthevalveangearealigned,possiblyturning

the actuator on the coupling by one tooth. If necessary, turn the crank wheel slightly towards

OPENorSHUTuntiltheholesarealigned.Ensurecorrectalignment(ifapplicable)and

completecontactofthemountingfaces.Fixactuatorwithscrews(atleastquality8.8)and

spring washers; Tighten screws alternately and gradually up to the torque given in Table 3,

below.

Fig. 2: Coupling / Assembly of actuator and valve

Attention

Table 3. Dimensions for coupling and

tightening torques for screws

Connection

X max.

(mm)

Y max.

(mm)

size

T

A

(Nm)

F05 0,5 3 4 x M6 10

F07 0,5 3 4 x M8 25

F10 0,5 3 4 x M10 50

coupling

grub screw

valve

A B

Y

X

Loading...

Loading...