Adjust Mode

Sliding the RUN/PRG/ADJ mode switch to the ADJ position allows the user to perform Expert TEACH/SET methods and Manual

Adjustment of the threshold(s).

TEACH Procedures

The instruction manual has detailed instructions for these TEACH modes:

• Two-Point TEACH

• Dynamic TEACH

• Window SET

• Light SET

• Dark SET

• Calibration SET

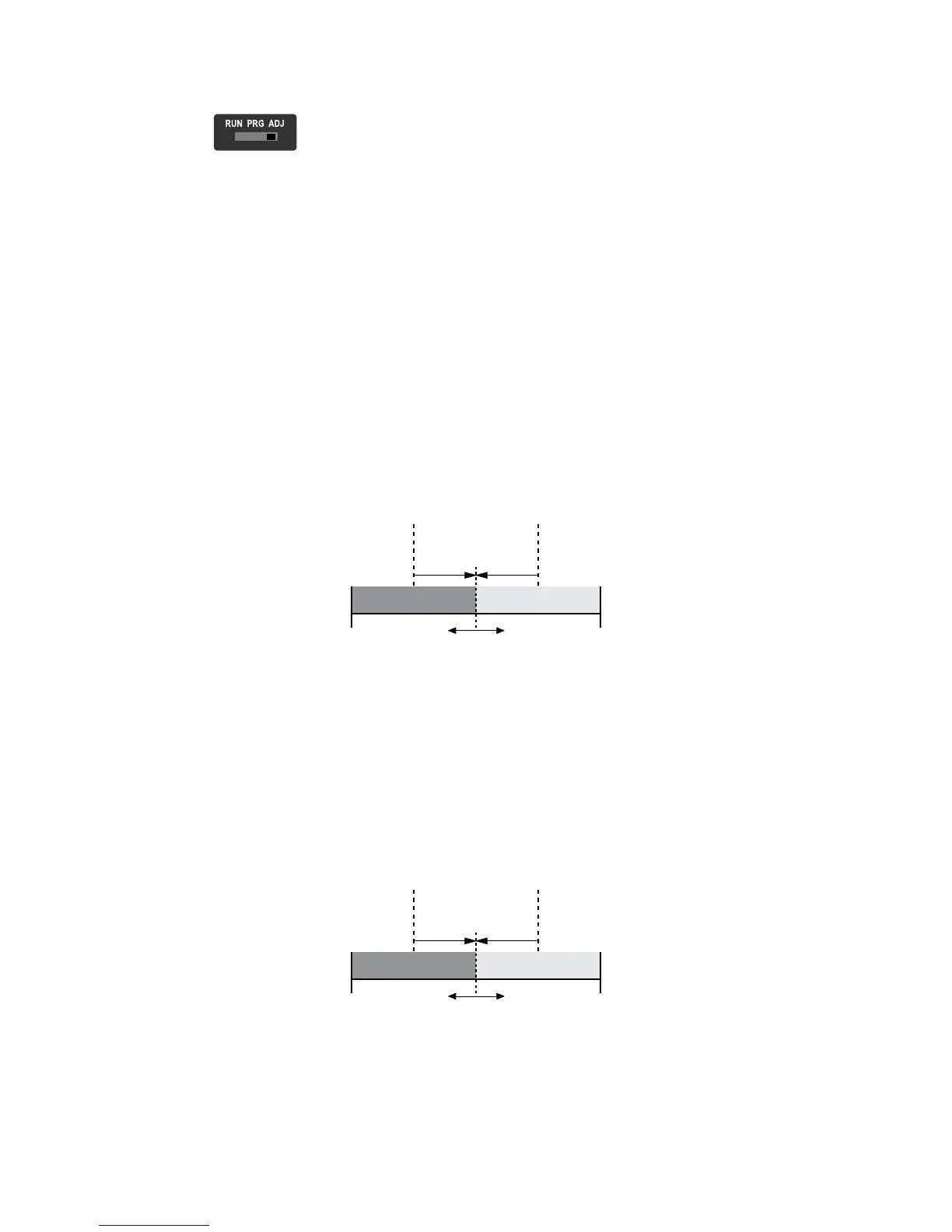

Two-Point TEACH

• Establishes a single switching threshold

• Threshold can be adjusted by using the "+" and "-" rocker button (Manual Adjust)

Two-Point TEACH is used when two conditions can be presented statically to the sensor. The sensor locates a single sensing

threshold (the switch point) midway between the two taught conditions, with the Output ON condition on one side, and the Output

OFF condition on the other.

Sensor positions

threshold midway

between taught conditions

Darkest

(no signal)

Most Light

(saturated

signal)

Output OFF Output ON

Darkest Taught

Condition

Lightest Taught

Condition

Position

adjusted by

Manual Adjust

Figure 2. Two-Point TEACH (Light Operate shown)

The Output ON and OFF conditions can be reversed by using the LO/DO (Light Operate/ Dark Operate) switch.

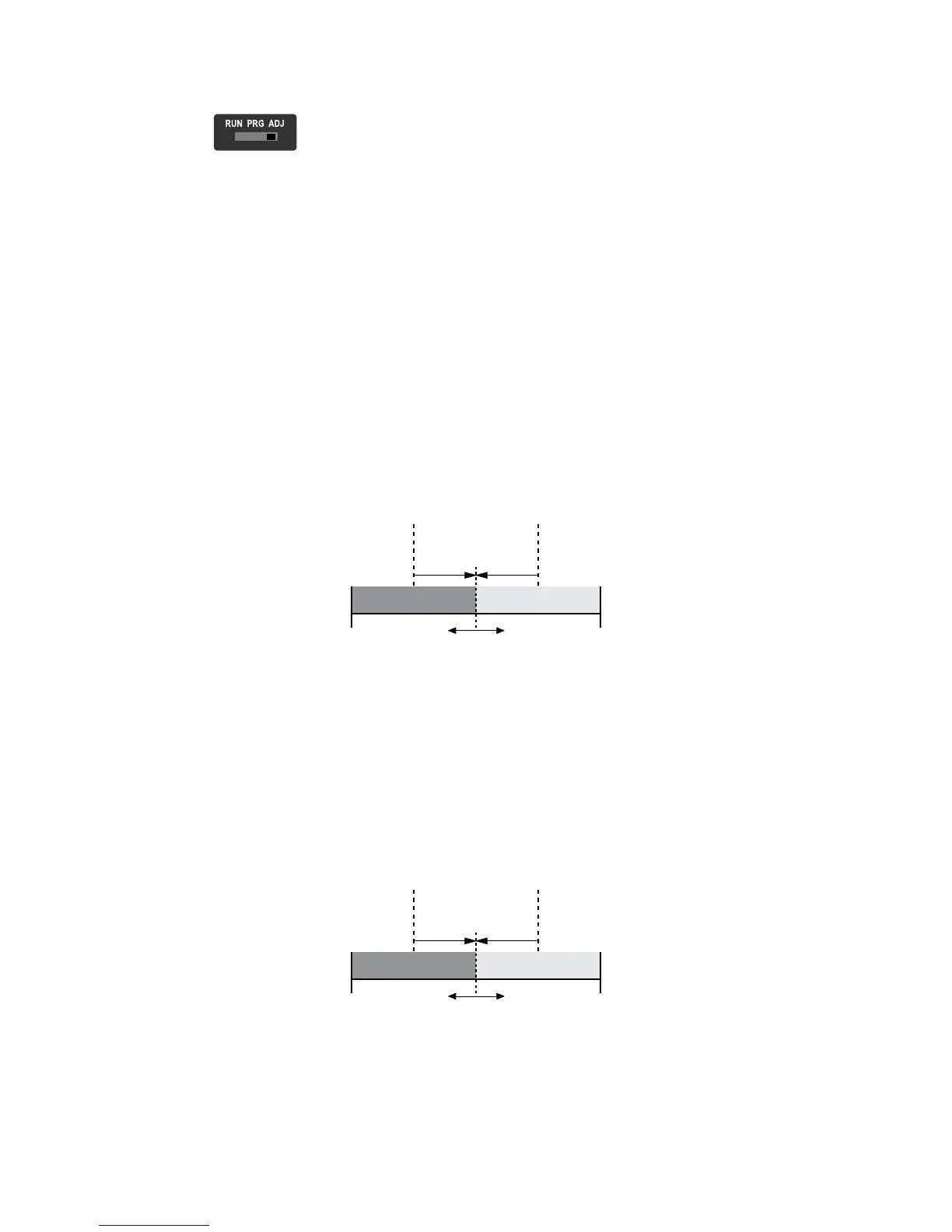

Dynamic TEACH

• Teaches

on-the-fly

• Establishes a single switching threshold

• Threshold can be adjusted using "+" and "-" rocker button (Manual Adjust)

Dynamic TEACH is best used when a machine or process may not be stopped for teaching. The sensor learns during actual

sensing conditions, taking multiple samples of the light and dark conditions and automatically setting the threshold at the optimum

level.

Sensor positions

threshold midway

between taught conditions

Darkest

(no signal)

Most Light

(saturated

signal)

Output OFF Output ON

Darkest Taught

Condition

Lightest Taught

Condition

Position

adjusted by

Manual Adjust

Figure 3. Dynamic TEACH (Light Operate shown)

The output ON and OFF conditions can be reversed using the LO/DO switch.

Window SET

• Sets window thresholds that extend a programmable % offset above and below the presented condition

DF-G1 Expert

™

Dual Display Fiber Amplifier

6 www.bannerengineering.com - Tel: + 1 888 373 6767 P/N 161275 Rev. E

Loading...

Loading...