Commissioning

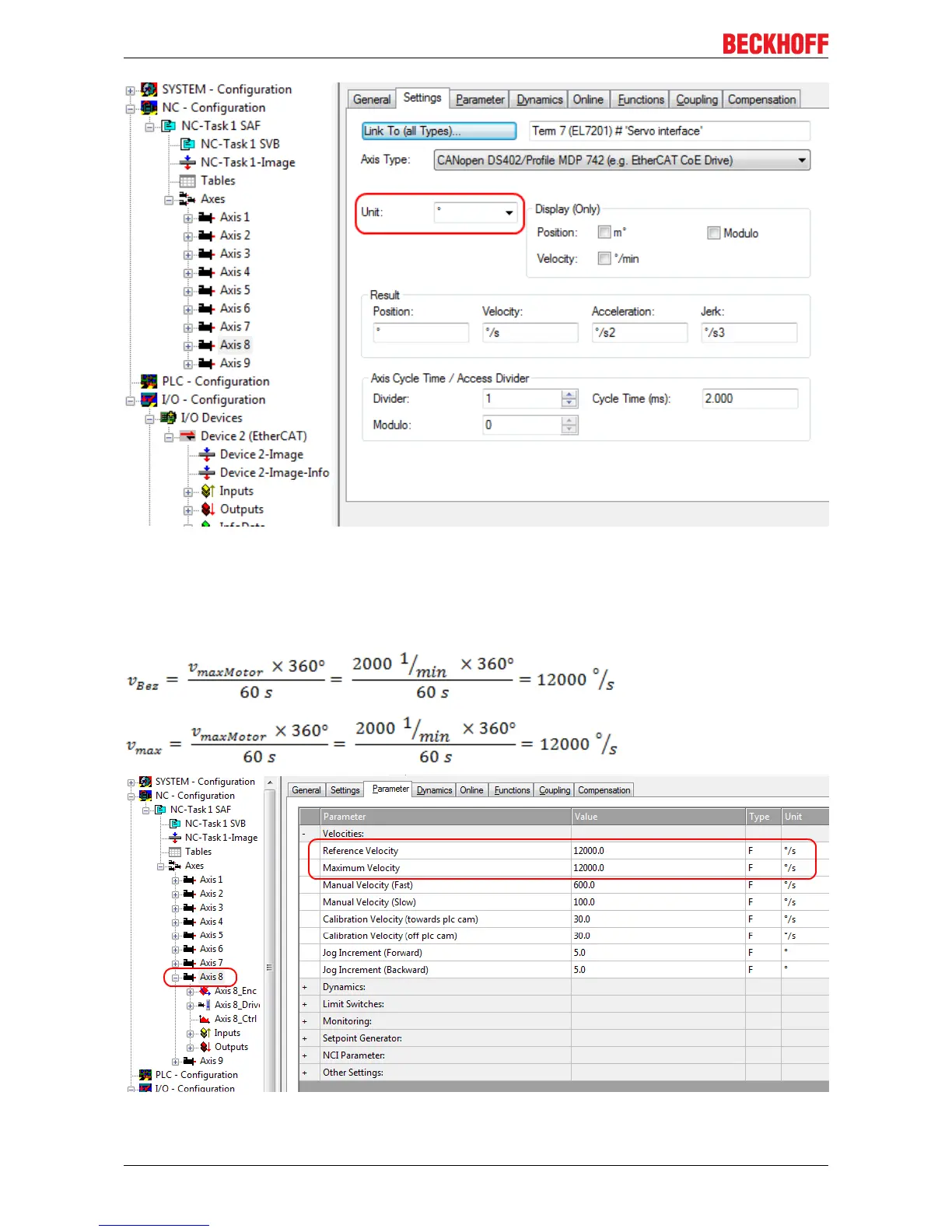

Fig.122: Definition of the unit

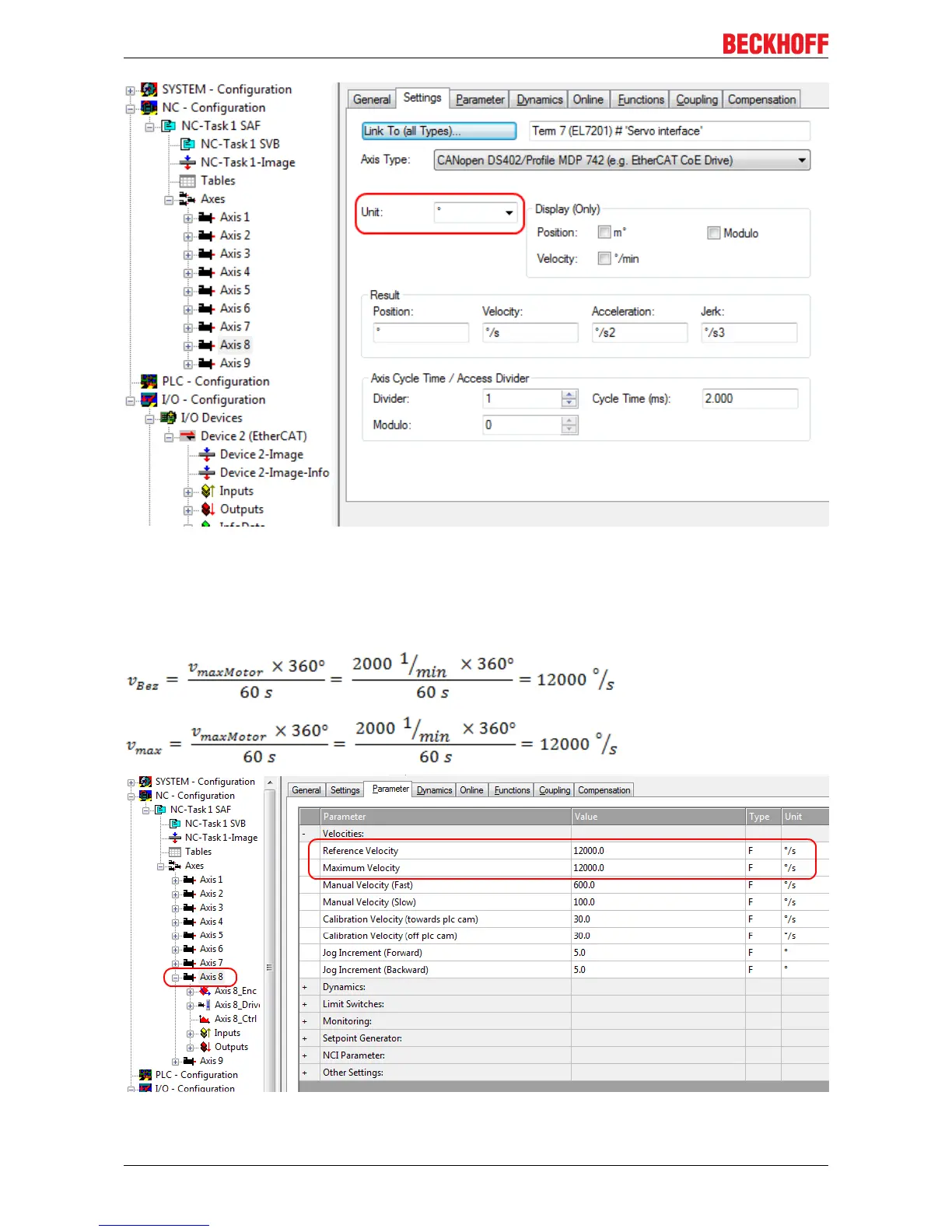

Selecting the maximum velocity

The maximum permitted velocity is calculated based on the maximum motor speed (name plate) and the

distance, in this case in relation to 360° per second.

Fig.123: Adjusting the reference velocity

EL72x1-001098 Version: 2.0

Loading...

Loading...