23

Bentone B40 MF/B45-2 MF

For installers

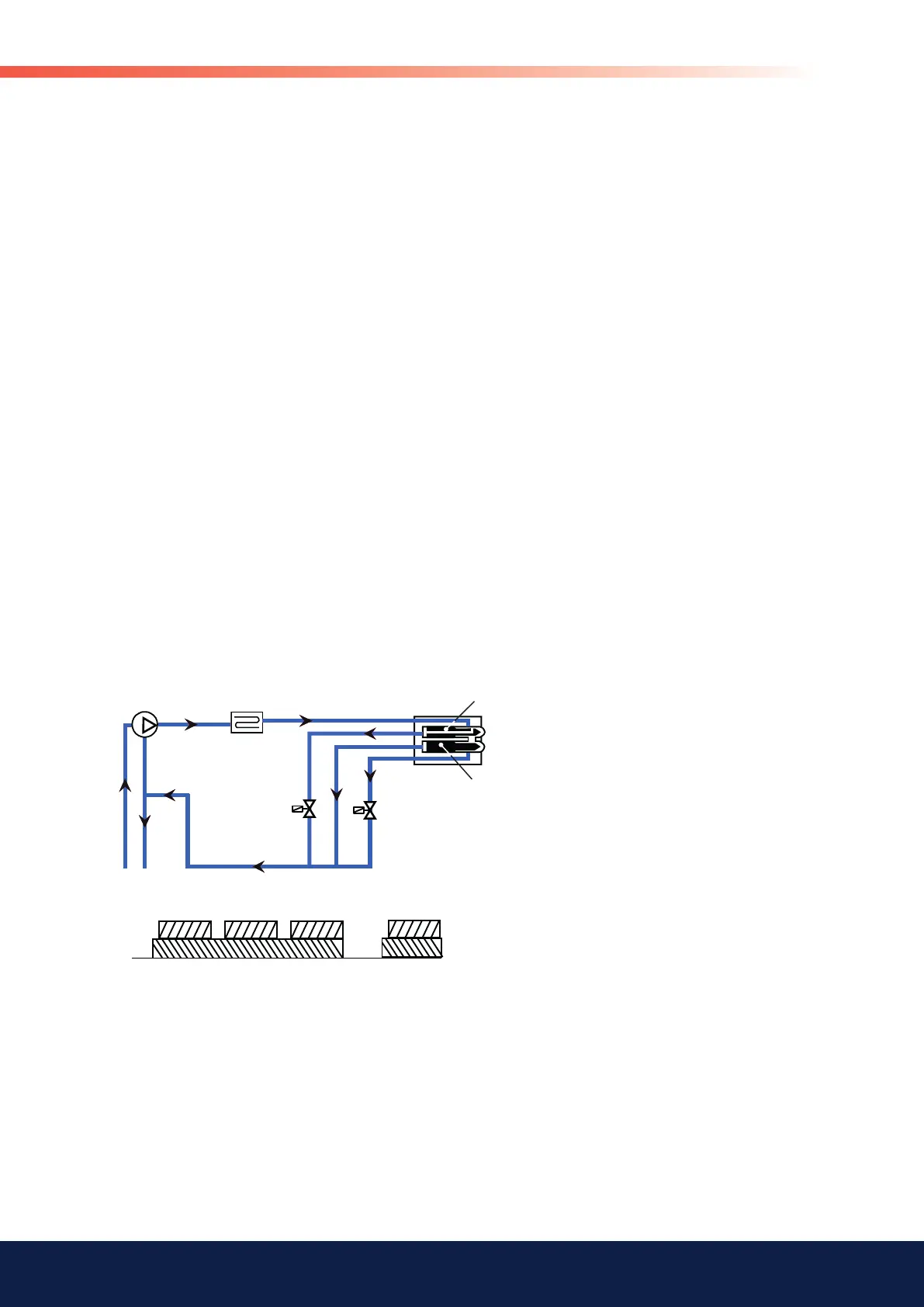

E1P

Y1

Y2

Y1

Y2

I

N

N

2

1

L

V1

V2

P Oil pump

E1 Preheater

I Nozzle assembly

L Leak pipe

N1 Nozzle 1

N2 Nozzle 2

Y1 Solenoid valve 1 NO

Y2 Solenoid valve 2 NC

V1 Cut valve 1

V2 Cut valve 2

3.2 B45-2 MF 2-stage burner

When the installation calls for heat, the burner's preheater starts to heat the

oil. Once the oil reaches the set temperature, the burner receives the signal

to start. Hot oil is fl ushed throughout the burner's oil system.

After the end of the blow period, the min. load solenoid valve (Y1) receives

voltage and closes. The oil pressure builds up in the nozzle holder and the

cut valve (V1) for min. load opens. The oil is atomised in the nozzle (N1) and

ignited. A small amount of oil and the nozzle assembly compressed air fl ow

is channelled back to the return side of the pump through the leak oil line (L).

Solenoid valve (Y2) for maximum load opens when the installation calls for

maximum load. The pressure difference created over the cut valve (V2) for

maximum load makes this valve open. The oil is atomised in the nozzle and

ignited.

When the heat in the installation reaches break temperature, solenoid valve

(Y2) for maximum load closes to reduce to minimum load. The pressure

equalisation which then takes place over the max. load cut valve (V2) gets

this to close and the fl ame is reduced to min. load.

Once the installation has reached the desired temperature, a solenoid valve

(Y1) is rendered without power and then opened; cut valve (V1) is then

subsequently closed. This process extinguishes the burner fl ame. In the

same process, oil heating is also interrupted.

Loading...

Loading...