36

Bentone B40 MF/B45-2 MF

For installers

A

Y X V U

Z

W

!

Pressure piston (V) and O-ring (Z) should be replaced at least

every 10 year.

5.8 Check oil line seals

Where there are temperature fl uctuations in the burner oil system due to the

preheater being on the burner, this may result, after a period of operation, in

oil leaks occurring in the connection pipe's coupling element.

Therefore, check the tightness of the coupling element (A) after a period of

operation after installation of the burner and at each service.

If leakage has occurred, it is usually suffi cient to tighten the leaking coupling

element.

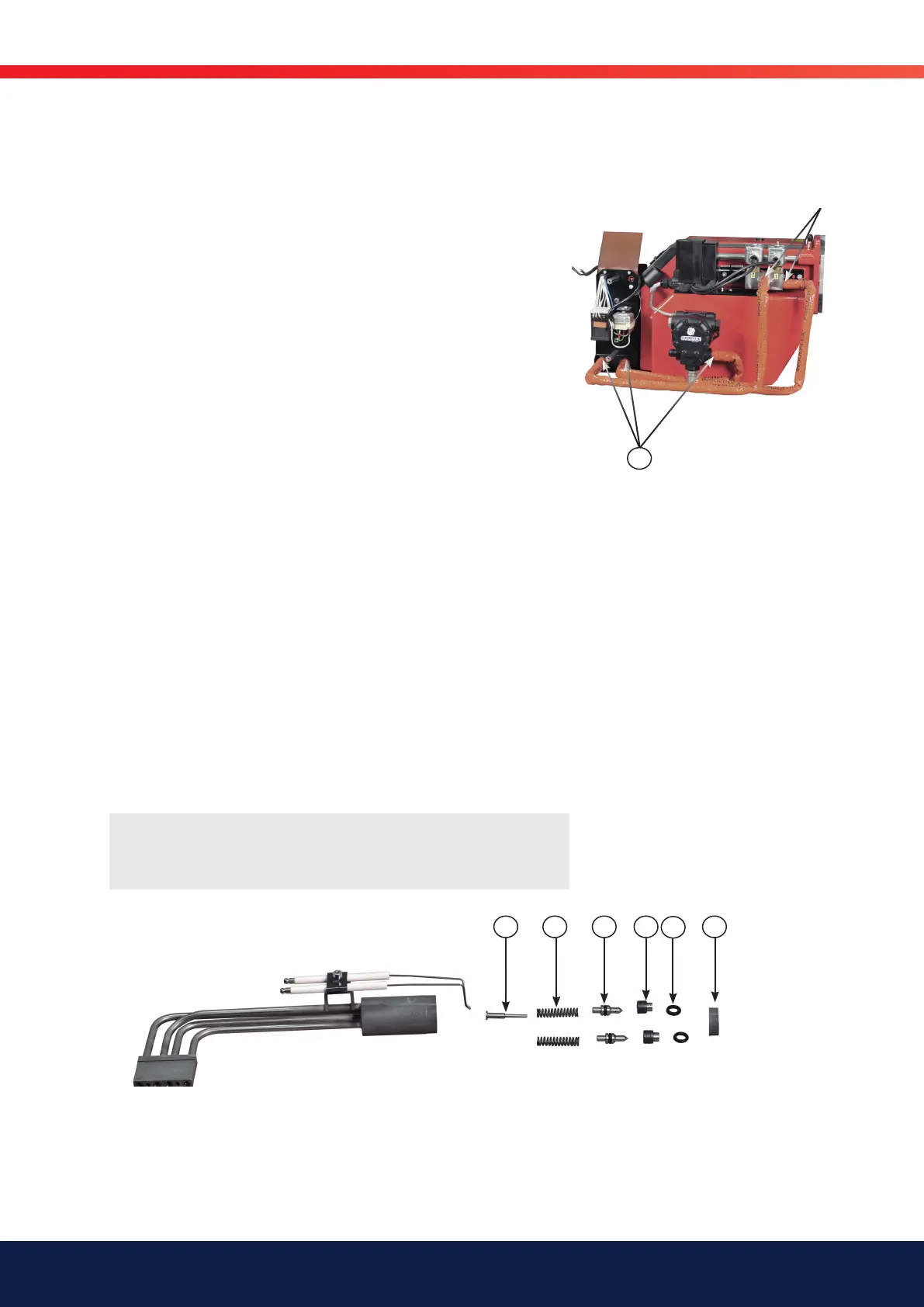

5.9 Check pressure piston nozzle

holder seals

As the pressure piston in the nozzle holder (see fi gure) constitutes a safety

component, the seal/function of the pressure piston should be checked on a

regular basis.

1. Allow the burner to begin its start-up sequence.

2. Turn off the burner just before it shall release oil through the nozzle.

3. Break the main current and disconnect the Euro plugs from the burner.

4. Open the boiler/burner so that the burner tube/brake plate can be

checked.

5. Check whether the burner tube/brake plate is wet with oil.

a. If no oil can be seen, there is no leak

b. If there is oil, replace the seat (U) and pressure piston (V) and

the o-ring (Z). (see 5.10)

6. Restore the burner to operating condition.

7. Fit the Euro plugs and turn on the main current.

8. Start the burner. Check combustion. *

Note:

* When servicing/replacing components that affect combustion, an

analysis and soot test shall be carried out on the installation.

Loading...

Loading...