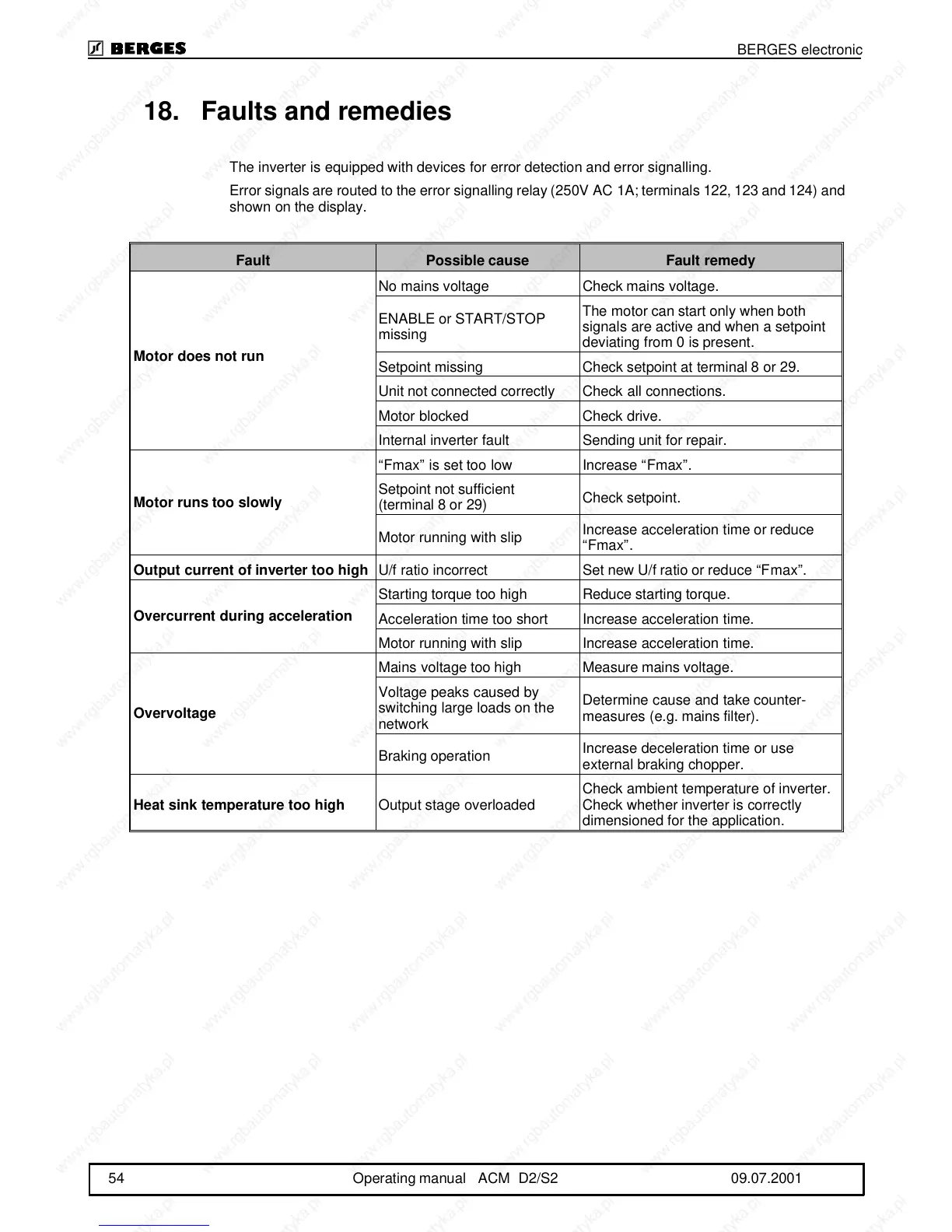

18. Faults and remedies

The inverter is equipped with devices for error detection and error signalling.

Error signals are routed to the error signalling relay (250V AC 1A; terminals 122, 123 and 124) and

shown on the display.

Fault Possible cause Fault remedy

Motor does not run

No mains voltage Check mains voltage.

ENABLE or START/STOP

missing

The motor can start only when both

signals are active and when a setpoint

deviating from 0 is present.

Setpoint missing Check setpoint at terminal 8 or 29.

Unit not connected correctly Check all connections.

Motor blocked Check drive.

Internal inverter fault Sending unit for repair.

Motor runs too slowly

“Fmax” is set too low Increase “Fmax”.

Setpoint not sufficient

(terminal 8 or 29)

Check setpoint.

Motor running with slip

Increase acceleration time or reduce

“Fmax”.

Output current of inverter too high

U/f ratio incorrect Set new U/f ratio or reduce “Fmax”.

Overcurrent during acceleration

Starting torque too high Reduce starting torque.

Acceleration time too short Increase acceleration time.

Motor running with slip Increase acceleration time.

Overvoltage

Mains voltage too high Measure mains voltage.

Voltage peaks caused by

switching large loads on the

network

Determine cause and take counter-

measures (e.g. mains filter).

Braking operation

Increase deceleration time or use

external braking chopper.

Heat sink temperature too high

Output stage overloaded

Check ambient temperature of inverter.

Check whether inverter is correctly

dimensioned for the application.

BERGES electronic

54 Operating manual ACM D2/S2 09.07.2001

Loading...

Loading...