18 82.526 - HERMES

5. SPRAYER MAINTENANCE

5.1 PRACTICAL ADVICE

regular maintenance

By cleaning your sprayer regularly during and at the

end of spraying programs:

• You will avoid spreading phytosanitary residues on

crops,

• You will ensure a good distribution of the product

by avoiding clogged nozzles,

• You will extend the life of your sprayer.

fOam fOrming in the tank

If this occurs, reduce the motor speed to below

540 rpm or add an anti-foaming additive to the tank

contents during lling.

final fill:

When lling the tank for the last time, add only the

amount of water and product necessary to spray the

remaining area of eld.

maintenance at the end Of treatment:

The whole of the equipment should be rinsed internally

(including tanks, booms and nozzles) by following the

procedures ( 4.5, page 17).

• Wash the outside of the sprayer (

5.4, page 19).

• Check the cleanliness of the nozzles and lters

(

5.2 and 5.3).

• Put the sprayer away.

WARNING:

Carry out sprayer maintenance

operations with the tractor engine

switched off, the ignition off and the

power take-off disengaged.

IMPORTANT:

Do not add fuel oil to the spraying

mixture as an anti-foaming agent.

5.2 FILTERS

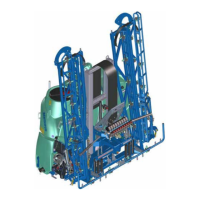

main tank suctiOn filter

The suction lter (2) is located in the control station.

To clean the lter cartridge, you must position the

index on the wheel on function

and valve (B) in

position ( 4.4, page 16).

To remove the lter cartridge, unscrew nut (1) from

the lter.

NOTE:

6/10 mesh lter cartridge tted as

original equipment (10/10 available as

a replacement for liquid fertiliser).

rinsing tank suctiOn filter

The suction lter is located between the tank outlet

connector and the non-return valve.

delivery filter

The delivery lter (3) is located in the control station.

It provides additional ltering.

To clean the filter cartridge, you must place the

index on the wheel on function

and valve (B) in

position ( 4.4, page 16).

To remove the lter cartridge, unscrew nut (4) from

the lter.

NOTE:

4/10 mesh lter cartridge tted as

original equipment (8/10 available as a

replacement for liquid fertiliser).

19

1

4

3

B

2

IMPORTANT:

The lter cartridge must be cleaned

after every application. Grease seals.

Loading...

Loading...