INTRODUCTION

Because of the wide range of function

generators currently available, and the wide

array of features which they offer, the inven-

tive user can undoubtedly devise many more

applications than can be covered here.

Therefore, this section endeavors to cover

some basic applications using features found

on the hypothetical generator presented in the

T Y P I C A L CONTROLS section of this

guidebook. It is hoped that the user can utilize

these basic ideas, perhaps improvising or

improving upon them as the particular situa-

tion dictates. The reader should note that

these descriptions have been generalized to

some degree to account for differences in

specific generators.

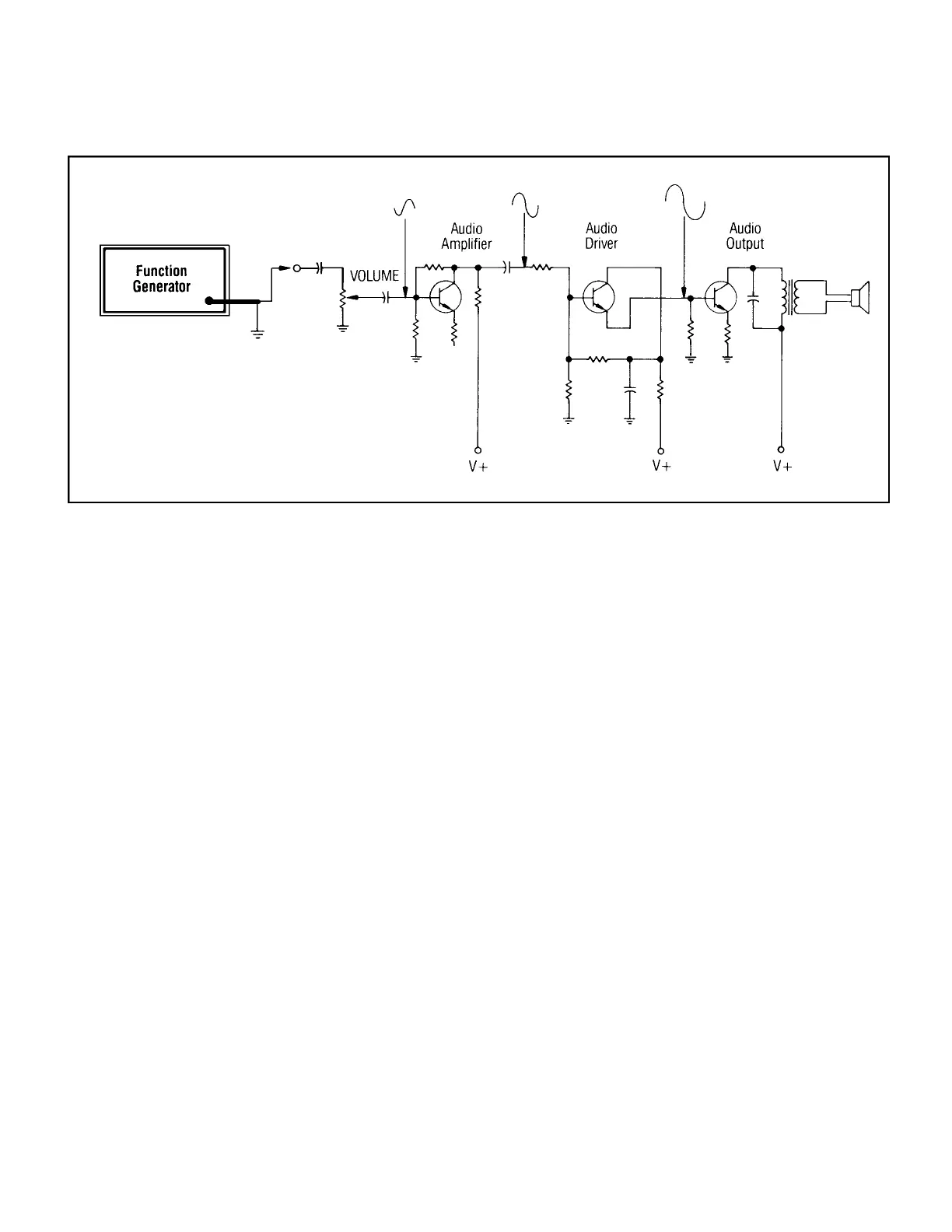

TROUBLESHOOTING BY S I G N A L

TRACING

One of the most common methods of

troubleshooting defective audio equipment is

to inject a signal from a function generator at

the input of the device under test. An oscillo-

scope is then used to check the output at each

stage, starting nearest the input and moving

toward the output. The stage which has no

output or distorted output is presumed to be

defective. A typical application is presented

in Fig. 6. The input signal is usually a sine

wave of low enough amplitude so as not to

produce undesired clipping in later stages.

Also, there is usually no DC offset present,

although, as shown in the figure, most ampli-

fiers incorporate an input capacitor to block

any DC component.

The technique is equally applicable to

non-audio equipment. Most function genera-

tors can produce signals up to 1 MHz, with

some models capable of 5 MHz or higher.

TROUBLESHOOTING BY S I G N A L

SUBSTITUTION

A variation on the signal tracing tech-

nique is to inject an audio signal at various

points in the circuit under test, to substitute

for the normal signal. In this technique, the

signal is first injected nearest the speaker and

is moved toward the audio input one stage at

a time until no sound is heard from the speak-

er. The stage that produces no sound is pre-

sumed to be defective.

One precaution: make sure that the DC

offset matches the normal operating voltage

at each point of signal injection. Improper DC

offset could bias a normally operating stage

to cutoff and make it appear defective; it

could also damage the circuit under test. A

coupling capacitor may be used to block the

DC offset and allow the signal to float at the

DC level of the point of injection if desired.

The signal amplitude should simulate the

normal signal levels used in the circuit where

signal is being injected.

This technique is also applicable to non-

audio equipment. Connect an oscilloscope,

voltmeter, or any other device which will

indicate the presence or absence of output.

If the equipment under test is already

handling one or more signals that could be

confused with the test signal, use sweep or

tone burst operation on the function generator

to produce unique sounds or signals. These

should be easily distinguishable from any

other signals that may be present.

USING A FUNCTION GENERATOR AS

A BIAS AND SIGNALSOURCE

Most modern function generators are able

to superimpose a DC offset voltage on their

AC signal output. As shown in Fig. 7, this

capability can be used to bias a transistor

amplifier under test as well as furnish the AC

component of the input signal. By observing

the amplifier output on an oscilloscope, the

amplitude and bias of the transistor can be

optimized for maximum undistorted output.

By varying the DC offset, the effects of vari-

ous types of bias (class A, B, and C) can be

determined.

9

APPLICATIONS

FIG. 6. Possible signal tracing points in a simple amplifier.

Loading...

Loading...