Toplift / Toplift ECO

28 92023200095

8 WARRANTY

The warranty period of the TOPLIFT is 12 months

from the supply date.

The conditions for claims are: defective construction,

faulty material or faulty execution. Such defects have

to be reported immediately to the supplier in writing.

Replaced parts become property of the supplier.

Damage caused by natural wear cannot be claimed.

No warranty is given on the damage caused by:

• Faulty use or application.

• Faulty assembly of the hoist.

• Faulty or careless treatment, in particular in re-

gard to these operating instructions.

• Excessive use and

• By the use of inappropriate equipment or spare

parts.

If the products are sent to our factory for repair and if

damages occur due to faulty packaging, they will be

at buyer’s expense.

9 MAINTENANCE

9.1 Maintenance intervals

General

The TOPLIFT has to be checked, depending on

the operation frequency, at least once a year by a

competent person.

Make sure that replaced parts are disposed in a

safe way in accordance with the requirements of

environmental protection.

The maintenance comprises visual checks, func-

tional checks and cleaning.

The intervals are indicated as follows:

w weekly

3 M 3- monthly

12 M annually

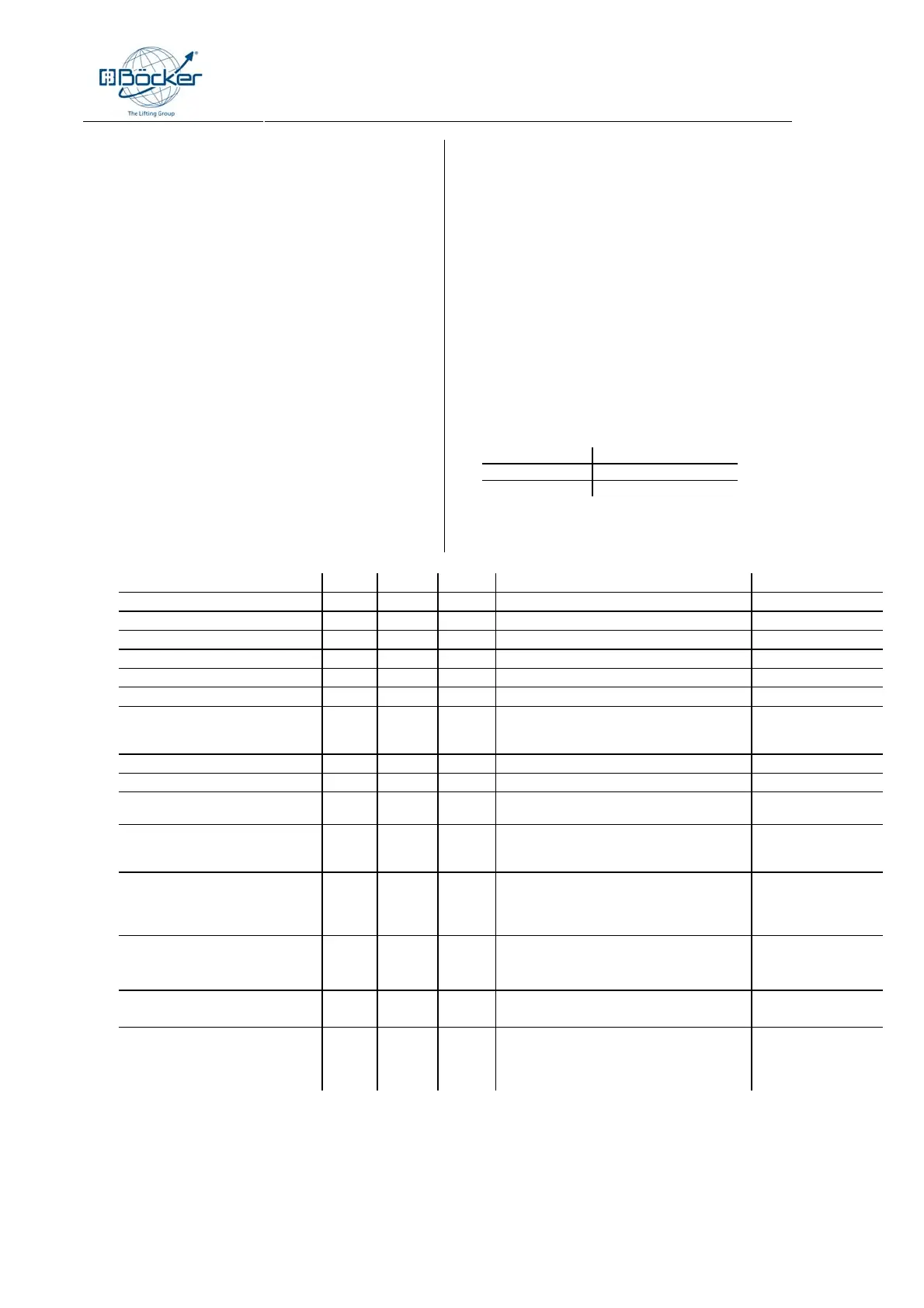

Description w 3 M 12 M

ctivit

Comments

Instruction and load labels X

Visual check

legibility

Drive Unit X

Functional check

Upper limit switch X

Functional check

Lower limit switch X

Functional check

Electrics X

Functional check

Supply line X

Visual check

Rope X

Visual check

Breakage of strands, birdcaging, cor-

rosion, kinks, squeezing

see chapter 9.3

Broken rope device X

Functional check see chapter 9.7

Pulleys carriage

X

Functional check

Pulley head

section

X

Functional check

Pulleys bend section

X

Functional check

The pulleys have to be cleaned of

concrete and mortar.

Slack rope device

X

Functional check

The slack rope device has to be regu-

larly cleaned of concrete and mortar

so that it is always operative.

Extensions

screws/nuts

condition of welds

X

X

X

Visual check

Visual check

Visual check

External electric terminals on

the drive unit

x

Visual check

Periodic checking and testing

by the operational safety or-

der in accordance with BGV

D7

X Testing by a competent person

Sea appendix

Loading...

Loading...