Toplift / Toplift ECO

29 92023200095

9.2 Changing the rope

The operational security and the lifetime of the rope

depends on proper use and good maintenance. It is

important to totally unwind the rope regularly and ex-

amine the rope for damage. The rope has to be

regularly cleaned from old grease, dust and corro-

sion and has to be lubricated.

9.3 Checking the rope and discarding

The ends of the rope have to be properly attached.

Upon checks by the competent person the rope has

to be checked for fractures. Damage that is visually

easy to establish are: Kinks, untwisting, crushings,

sharp bends, corrosion, birdcaging, strong reduction

of the rope diameter and breakage of a strand.

Attention! Always wear gloves when re-

placing the rope.

Before fiitting unroll the wire rope completely on the

ground before fitting to the drum to avoid twisting.

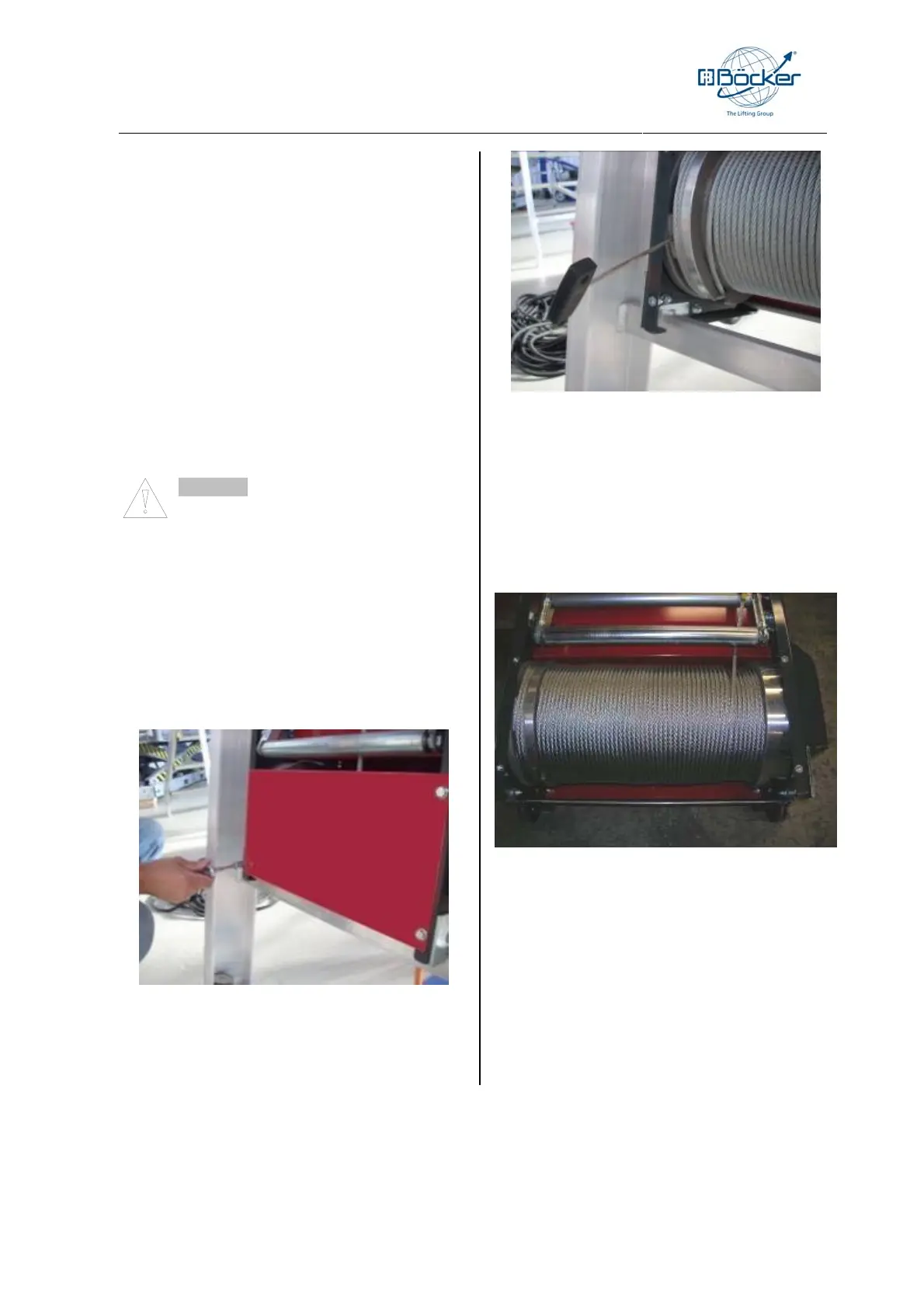

9.4 Fitting of the hoisting rope on the

cable drum Toplift 225 Universal /

234 / 240 / Furniture

• Remove the front wall by loosening the four

hexagon screws.

• Remove the old cable from the drum winch and

dismantle the cable lock for the new cable.

• Loosen the hex socket screw (use a 4mm hex

socket wrench) on the left-hand side of the

winch in order to be able to remove the cable

• Completely unroll the new cable on the floor.

• Now place the cable onto the drum winch

from the left.

• The cable is placed onto the cable drum by

three winds and clamped in using the hex

socket screw (use a 4mm hex socket

wrench).

• Push the button UP and wind the rope on the ca-

ble drum. See to it that the windings lay properly

next to each other

• Then guide the end of the cable through the roll-

ers of the slack cable safety device and secure

the front wall using the four hexagon screws.

Loading...

Loading...