Aufstellung.pm6.5 - USA

Page 3.6

Installation

BOGE Operating instructions for S 40-2...S 341 / SF 40-2...SF 220 series screw compressors

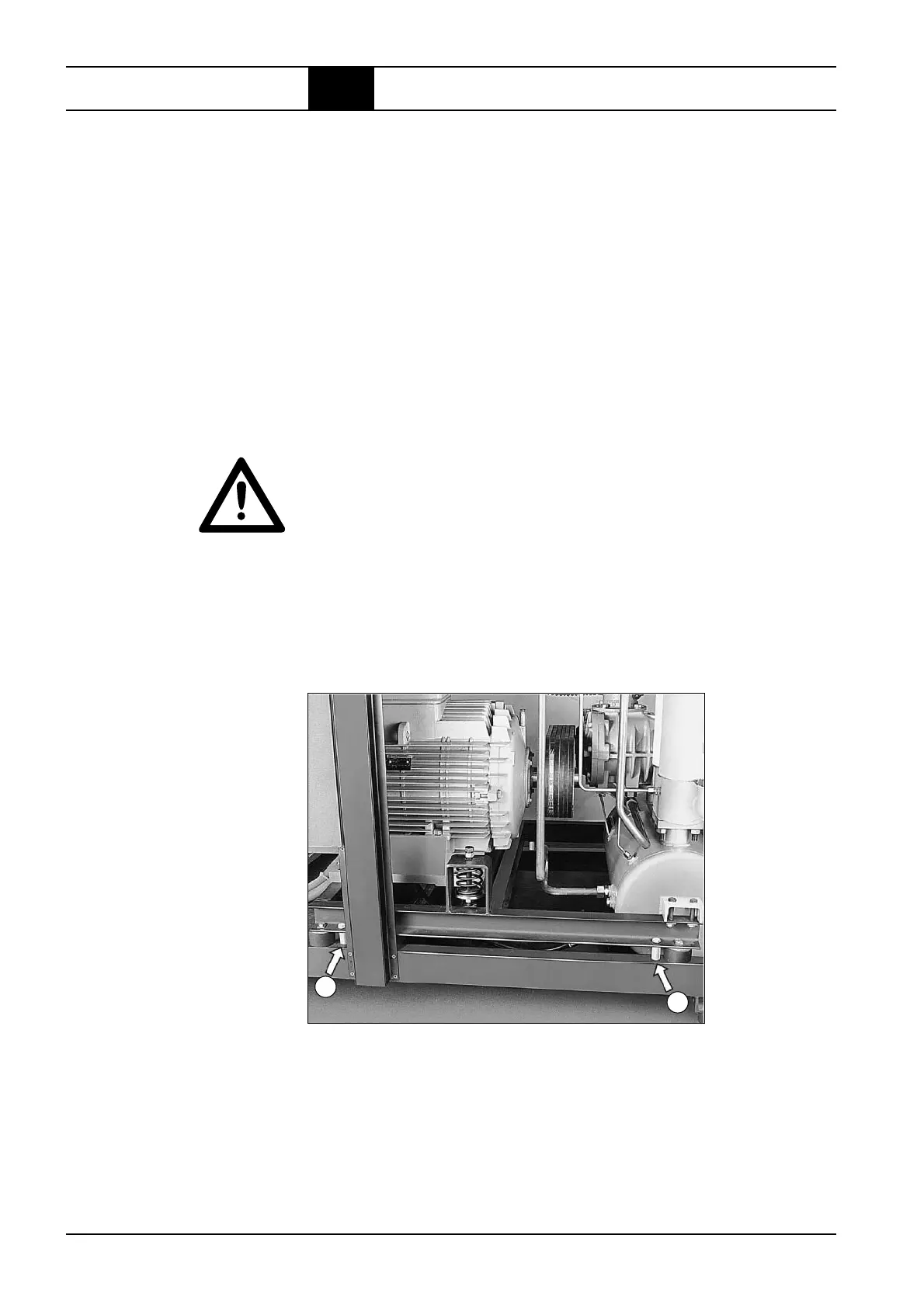

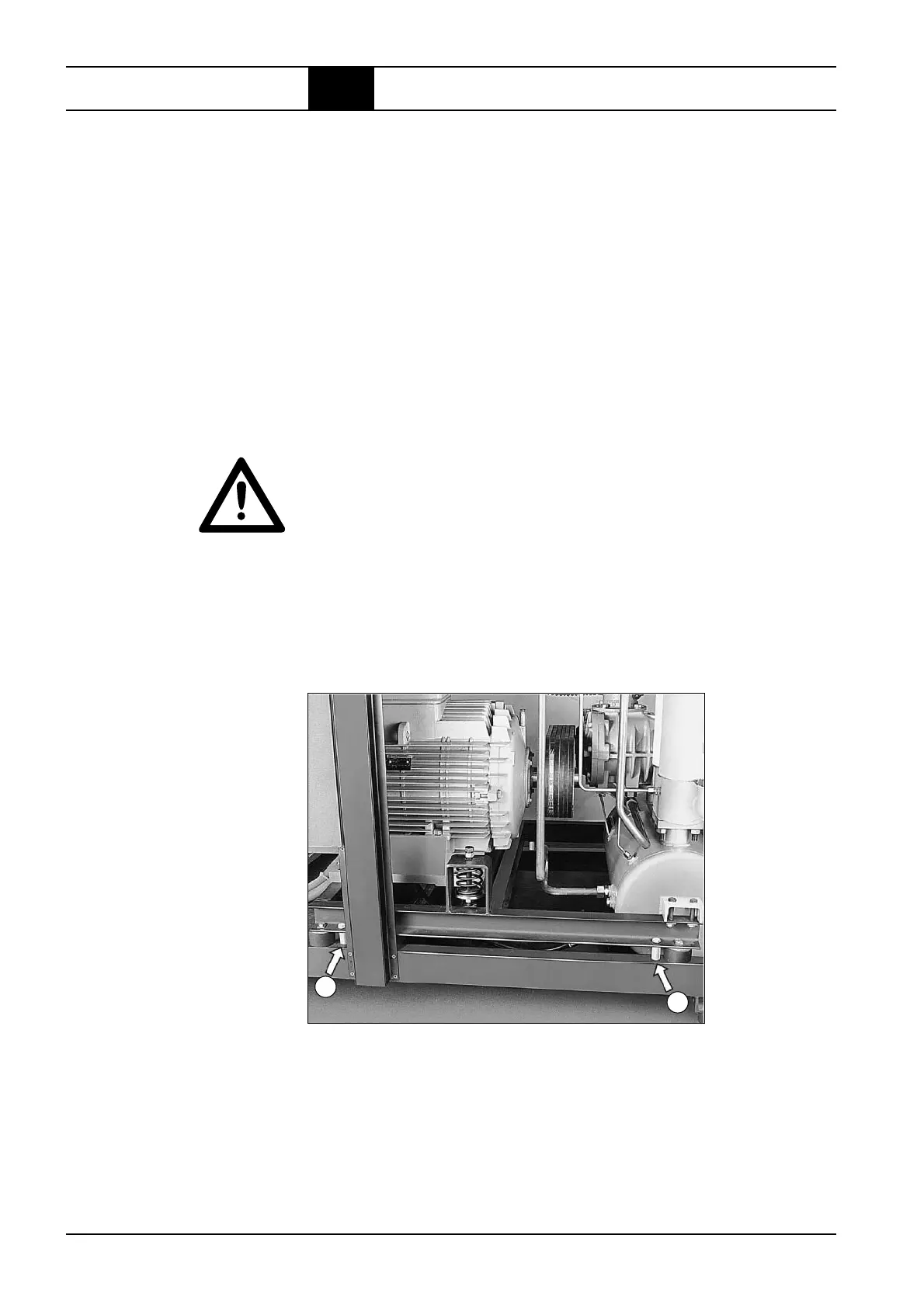

Removing the transport

securing bolts

Fig. 3.1: Removing the transport securing bolts Note:

3.3 Installation

Note: Demonstration example. Compressor may only be operated with the switch cabinet

closed and all panels fitted.

Connecting the

cooling water (option)

The pipework for the cooling water circuit in the compressor is completely

installed at the factory.

Only the following work must be performed during installation:

– Check, whether the water supply has the required data and whether the

cooling water quality is adequate (see page 2.10).

– Connect the cooling water supply and discharge line to the water supply.

The following component parts must be provided by the customer for cooling

water installation:

– Dirt traps

The dirt trap at the cooling water inlet protects the cooling units against

sediment collecting. Pore width: max. 0.6 mm

– Expansion vessel and safety valve

ATTENTION!

If the stop valves in the supply and discharge lines are simultaneously closed

in a closed cooling system, an enclosed room will result. If the water heats

up in this room, it will expand and the pressure will increase.

Install an expansion vessel and a safety valve to prevent damage to the

cooling units.

The frame of the drive unit is bolted to the base frame for transport.

Remove the four red marked screws and (each two on the longitudinal

side) together with the space collars.

1

2

Loading...

Loading...