Wartung.pm6.5 - USA

Page 5.9

Maintenance

BOGE Operating instructions for S 40-2...S 341 / SF 40-2...SF 220 series screw compressors

5.3 Regular maintenance work

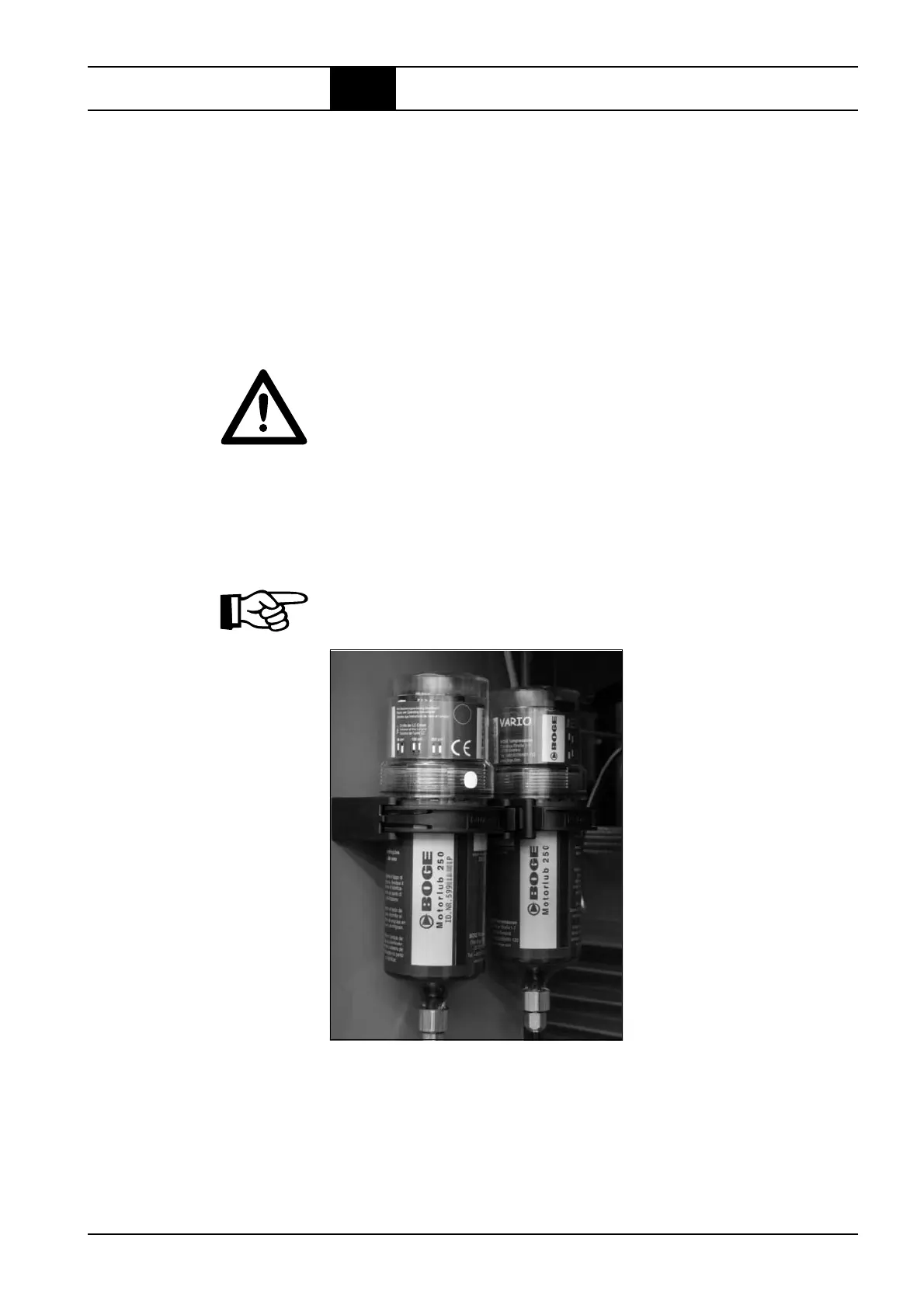

The drive motors have an automatic lubricating device (see figure).

There is a lubricating nipple on the A bearing and B bearing side of the motor.

The lubricating nipple is connected with the automatic lubricating device via

a tube.

The tubes are already filled with grease. When the tubes are replaced, they

must be filled with grease.

The type of grease is indicated on the lubrication unit of the compressor

(see Fig. 5.5 below).

Voltage is supplied from the switch cabinet.

Both LC units (LC = lubrication canister) are designed for 1 year in three-

shift operation. After one year, the canisters must be replaced because

of lubricant ageing, no matter how much lubricant they have.

So as to comply with the necessary lubricating deadlines, the coding switches

"VOL" and "TIME" of the drives are preset in the factory according to table

7.2 of the Operating Instructions for CONTROL TIME.

Set values:

– LC unit S250 for A bearing: 2.89 cm³/ per 100 operating hours

For information regarding operating and maintenance to CONTROL TIME,

please read enclosed operating instructions.

Servicing drive motor

Fig. 5.5: Automatic lubricating device CONTROL TIME

Loading...

Loading...