Wartung.pm6.5 - USA

Page 5.11

Maintenance

BOGE Operating instructions for S 40-2...S 341 / SF 40-2...SF 220 series screw compressors

Checking the oil level,

topping up oil

5.3 Regular maintenance work

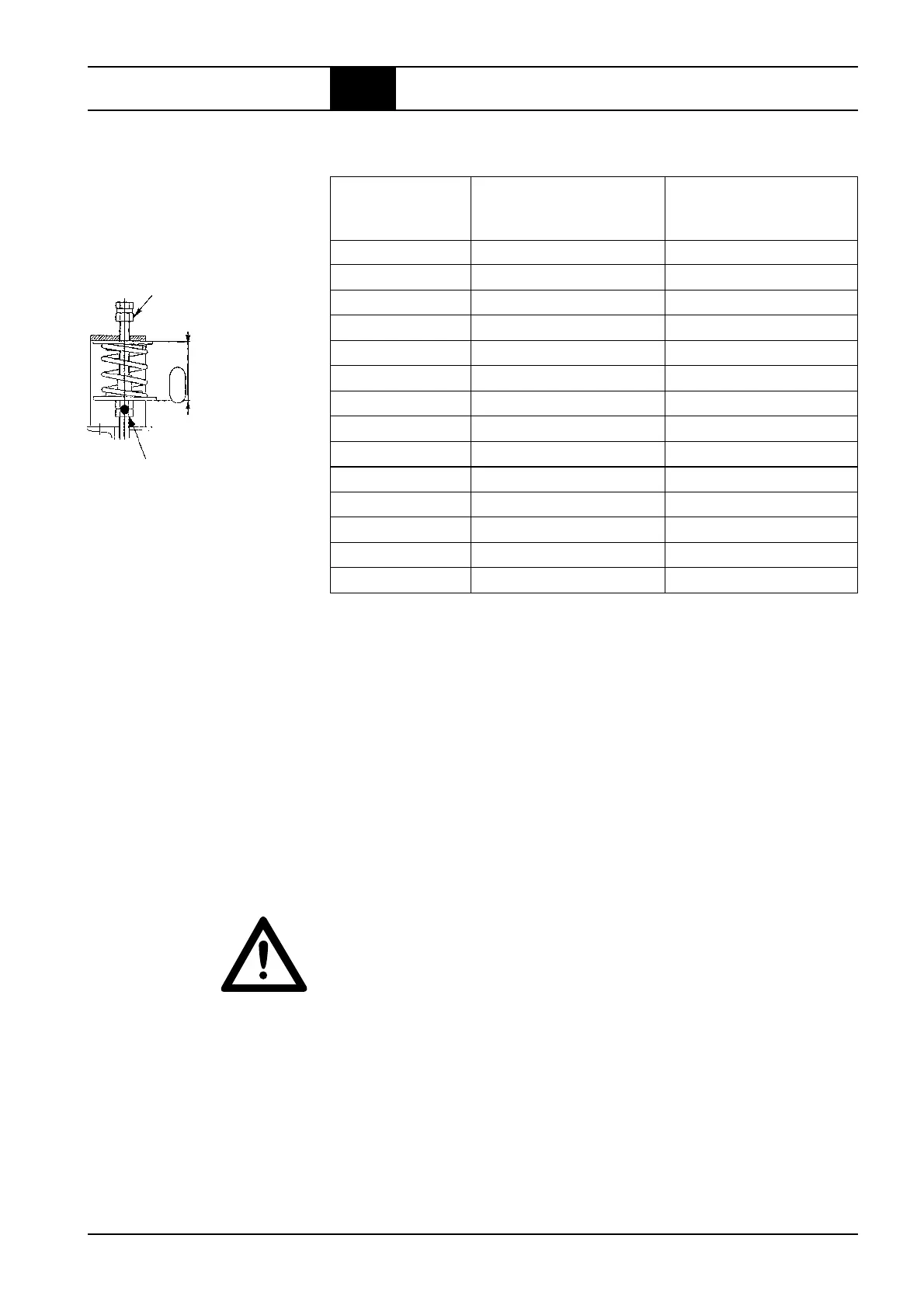

Belt tensioning device

Model Pressure Setting

+0/– 0.04

psig inch

S 40-2 / SF 40-2 100 / 115 / 125 / 150 / 190 4.4 / 4.4 / 4.4 / 4.4 / 4.4

S 50-2 100 / 115 / 125 / 150 / 190 4.4 / 4.4 / 4.4 / 4.4 / 4.4

S 60-2 / SF 60-2 100 / 115 / 125 / 150 / 190 4.4 / 4.4 / 4.4 / 4.4 / 4.4

S 61-2 100 / 115 / 125 / 150 / 190 4.4 / 4.4 / 4.4 / 4.4 / 4.4

S 75-2 100 / 115 / 125 / 150 / 190 4.4 / 4.4 / 4.4 / 4.4 / 4.4

S 100-2 / SF 100-2 100 / 115 / 125 / 150 / 190 4.4 / 4.4 / 4.4 / 4.4 / 4.4

S 101 100 / 115 / 125 / 150 / 190 4.4 / 4.4 / 4.4 / 4.4 / 4.4

S 125 100 / 115 / 125 / 150 / 190 3.6 / 3.8 / 3.8 / 3.7 / 3.9

S 150 / SF 150 100 / 115 / 125 / 150 / 190 3.6 / 3.4 / 3.4 / 3.4 / 3.0

S 151 100 / 115 / 125 / 150 / 190 3.6 / 3.4 / 3.4 / 3.4 / 3.0

S 180 100 / 115 / 125 / 150 / 190 3.6 / 3.4 / 3.4 / 3.4 / 3.5

S 220 / SF 220 100 / 115 / 125 / 150 / 190 3.5 / 3.3 / 3.3 / 3.4 / 3.5

S 271 100 / 115 / 125 / 150 / 190 4.0 / 4.0 / 3.8 / 3.8 / 4.8

S 341 100 / 115 / 125 / 150 / 190 3.5 / 3.5 / 3.2 / 3.2 / 4.6

The settings shown in the table are fixed by the manufacturer and may not

be changed. Slight deviations are allowed and compensated by the GM

drive system.

The current settings are also shown on the GM drive system. With special

versions the settings on the sticker may deviate from the standard values.

If the spring is not pre-tensioned at the set measure, the measure must be

reduced until the spring is slightly pretensioned (to prevent the spring clap-

ping).

Check: – Prior to commissioning/start-up of the compressor.

– Then every 1000 operating hours,

however at least once a year.

Topping up: – When the oil level has dropped below the "min" mark

(see sketch).

CAUTION!

Always use the same oil type when topping up.

Never mix different oil types and brands.

blue

sealed

Setting

inch

S 40-2 – S 341

Setting GM –

SF 40-2 – SF 220

Loading...

Loading...