Wartung.pm6.5 - USA

Page 5.10

Maintenance

BOGE Operating instructions for S 40-2...S 341 / SF 40-2...SF 220 series screw compressors

Changing the V-belt

Check: – 1x per year for damage.

Change: – At visible damage.

The BOGE GM drive system automatically adjusts the V-belt to the correct

V-belt tension in any operating mode.

Maintenance of the V-belt drive is limited to the above mentioned work.

– Switch off the compressor using the OFF button.

DANGER: Risk of injury!

Switch off the main switch and secure it against unintentional switch-on.

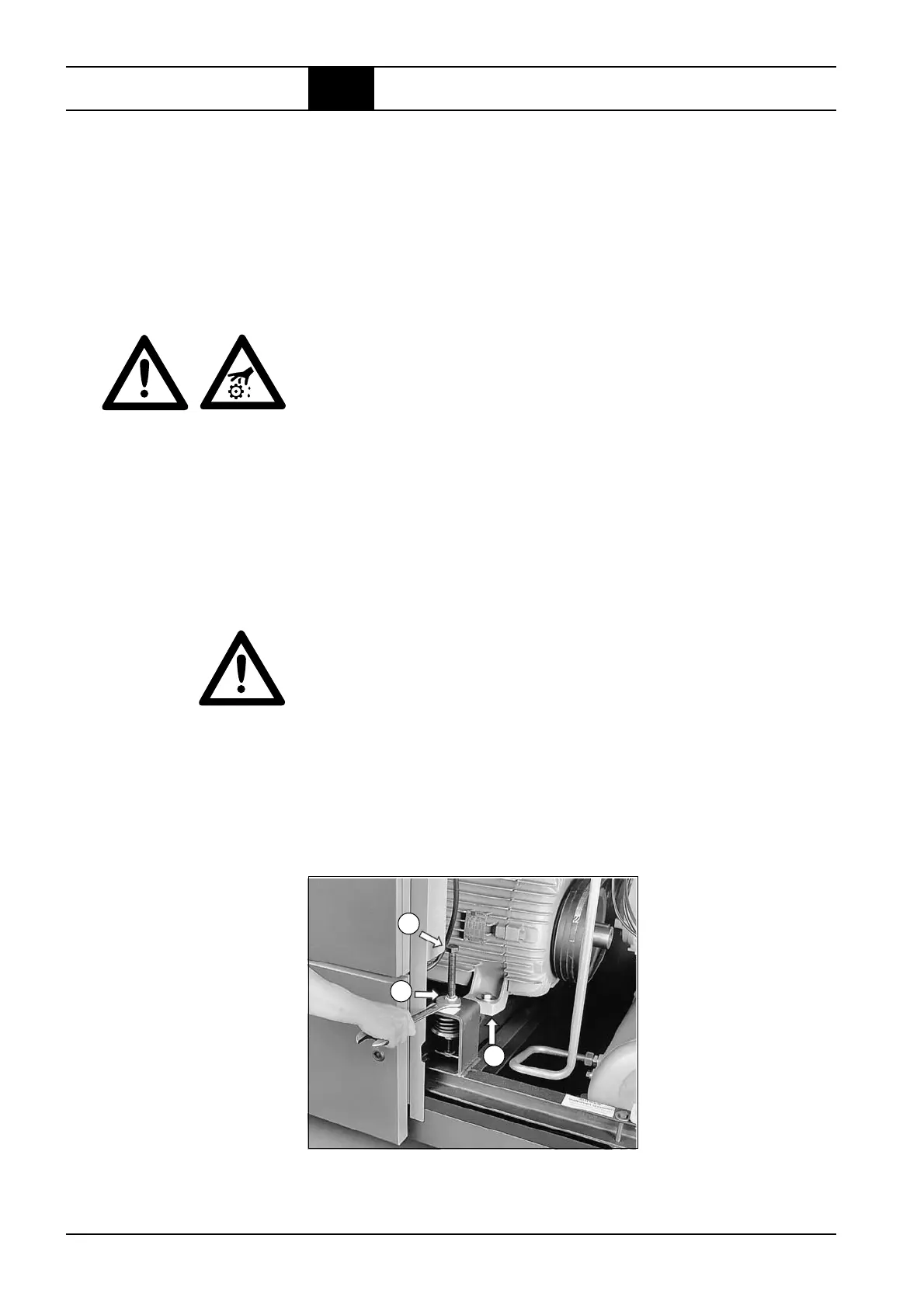

Slacken the V-belts:

– Remove cladding on the maintenance side as well as the belt protection.

– Secure screw head of the tensioning device with NW 27 spanner to

prevent it from turning.

– Turn locknut clockwise. Raise the motor in arrow direction until the

V-belts are fully slackened.

Change the V-belts:

– Remove the slackened belts from the belt pulleys.

– Fit new V-belts on the belt pulleys on the motor and compressor.

CAUTION!

The new V-belts must be of precisely the same length.

Only change the V-belts as a complete set!

Tensioning the V-belts:

– Lower the motor again. For this purpose, secure screw head against

turning, then turn locknut counterclockwise and lock by means of the

screw head. The V-belts are automatically correctly tensioned by the

BOGE GM drive system.

– Fit belt protection.

– Reattach cladding on the maintenance side.

5.3 Regular maintenance work

Note: Demonstration example. Compressor may only be operated with the switch cabinet

closed and all panels fitted.

3

4

5

Fig. 5.6: The BOGE GM

drive system

Note:

Loading...

Loading...