Wartung.pm6.5 - USA

Page 5.12

Maintenance

BOGE Operating instructions for S 40-2...S 341 / SF 40-2...SF 220 series screw compressors

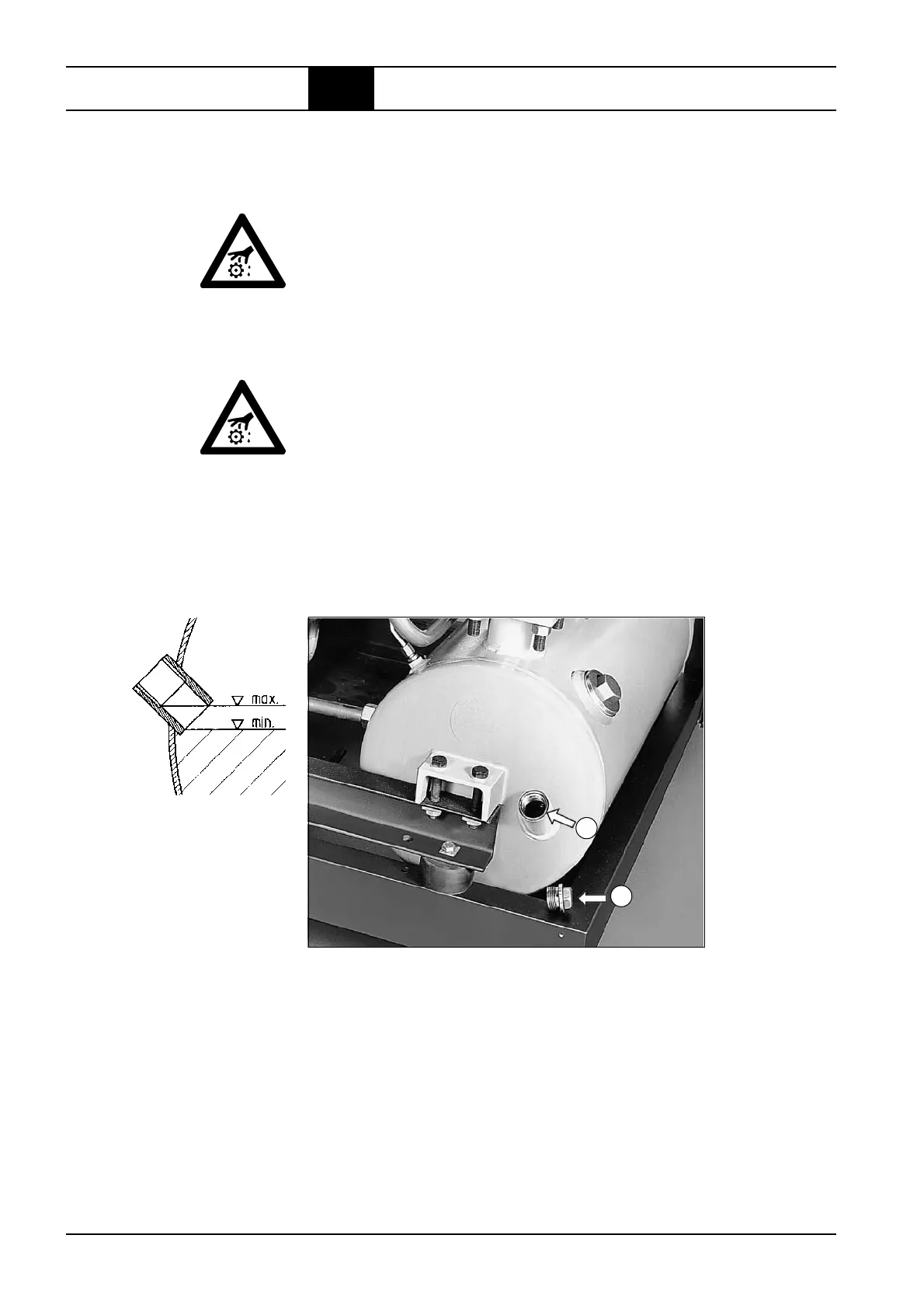

Fig. 5.7: Checking the oil level, topping up with oil Note:

– Switch off the compressor using the OFF button.

DANGER: Risk of injury!

Switch off the main switch and secure it against unintentional switch-on.

– Close ball valve at the compressed air outlet.

– Vent the compressor (as described in the beginning of the chapter).

The system pressure gauge must indicate a pressure of 0 psig.

– Wait approx. 3 minutes to permit the oil to settle.

– Remove cladding on the maintenance side.

DANGER: Risk of injury!

Danger of burning due to hot oil!

– Remove plug of oil filling socket .

– Check oil level.

The oil level must not drop below the "min" mark (see sketch).

– If necessary, top up with oil to the lower edge of the thread ("max." mark)

on the oil filling socket.

– Screw plug with viton seal back in.

– Reattach clading on the maintenance side.

– Open ball valve at the compressed air outlet.

5.3 Regular maintenance work

Note: Demonstration example. Compressor may only be operated with the switch cabinet

closed and all panels fitted.

1

2

Loading...

Loading...