Never run the gear unit when the shrink disc protective guard is not fitted.

5.1.5 ANCHORING THE TORQUE ARM

For shaft-mounting solutions the gear unit can be equipped with a torque arm on request.

This device, which is made of electrowelded steel and equipped with damper bushes, assures the

highest guarantees of functionality of the assembly because it is designed and sized specifically for

the job.

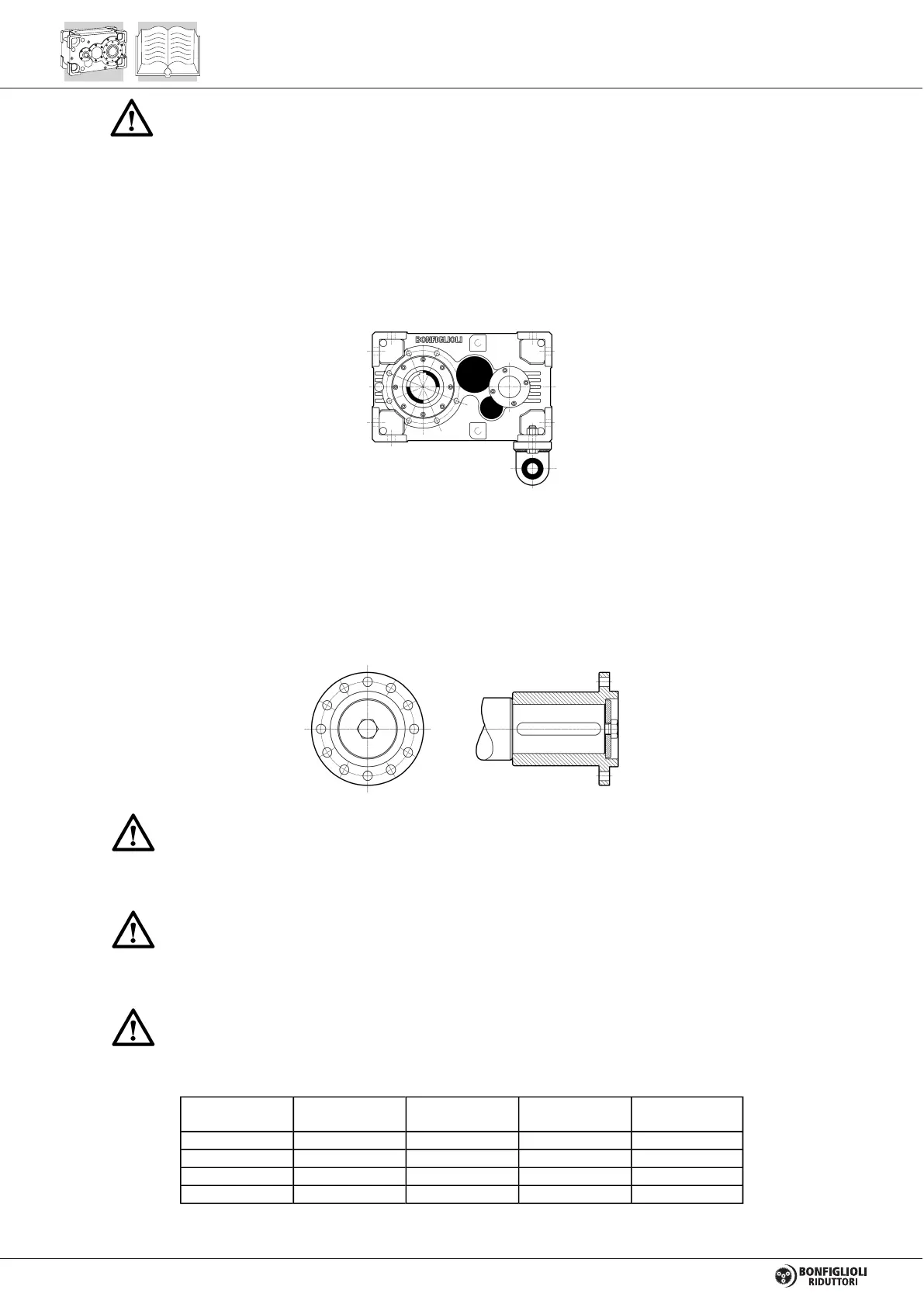

5.1.6 GEAR UNIT EQUIPPED WITH MANIFOLD FLANGE

Thoroughly clean and degrease the mating areas between the gear unit flange and

driven machine flange. The correct execution of this procedure is essential for safe torque

transmission. Do not use solvent with dirty rags to degrease the surfaces.

Do not use molybdenum disulphide or any other type of grease, as this would

significantly lower the friction coefficient in the contact area and therefore impair the

functionality of the coupling.

Tighten the bolts fully down, working in a crosswise sequence and applying the

maximum tightening torque shown in the chart by means of a torque wrench.

HDP 60

M18 cl. 10.9 cl. 10 435 Nm

HDP 70

M18 cl. 10.9 cl. 10 435 Nm

HDP 80

M20 cl. 10.9 cl. 10 615 Nm

HDP 90

M20 cl. 10.9 cl. 10 615 Nm

Screw

Thread

UNI 5737

Nut

UNI 5588

Tightening

torque

16

Loading...

Loading...