7.2.5 FORCED LUBRICATION WITH MOTOR PUMP

The system is composed of a motor pump with a separate power input, a coarse mesh filter, a

minimum pressure switch and the relative connecting pipelines.

To ensure the optimal supply of lubricant, the electric motor must be powered in compliance with the

rated values.

All electrical connections are to be made by the customer prior to starting of the gear unit.

The minimum pressure switch is equipped with electric contacts and supplies an alarm signal when

pressure in the lubrication system falls below the minimum permissible value (0.5 bar).

In the case of alarms, stop the gear unit and locate the cause of the problem.

The lubrication system must be started before starting the gear unit.

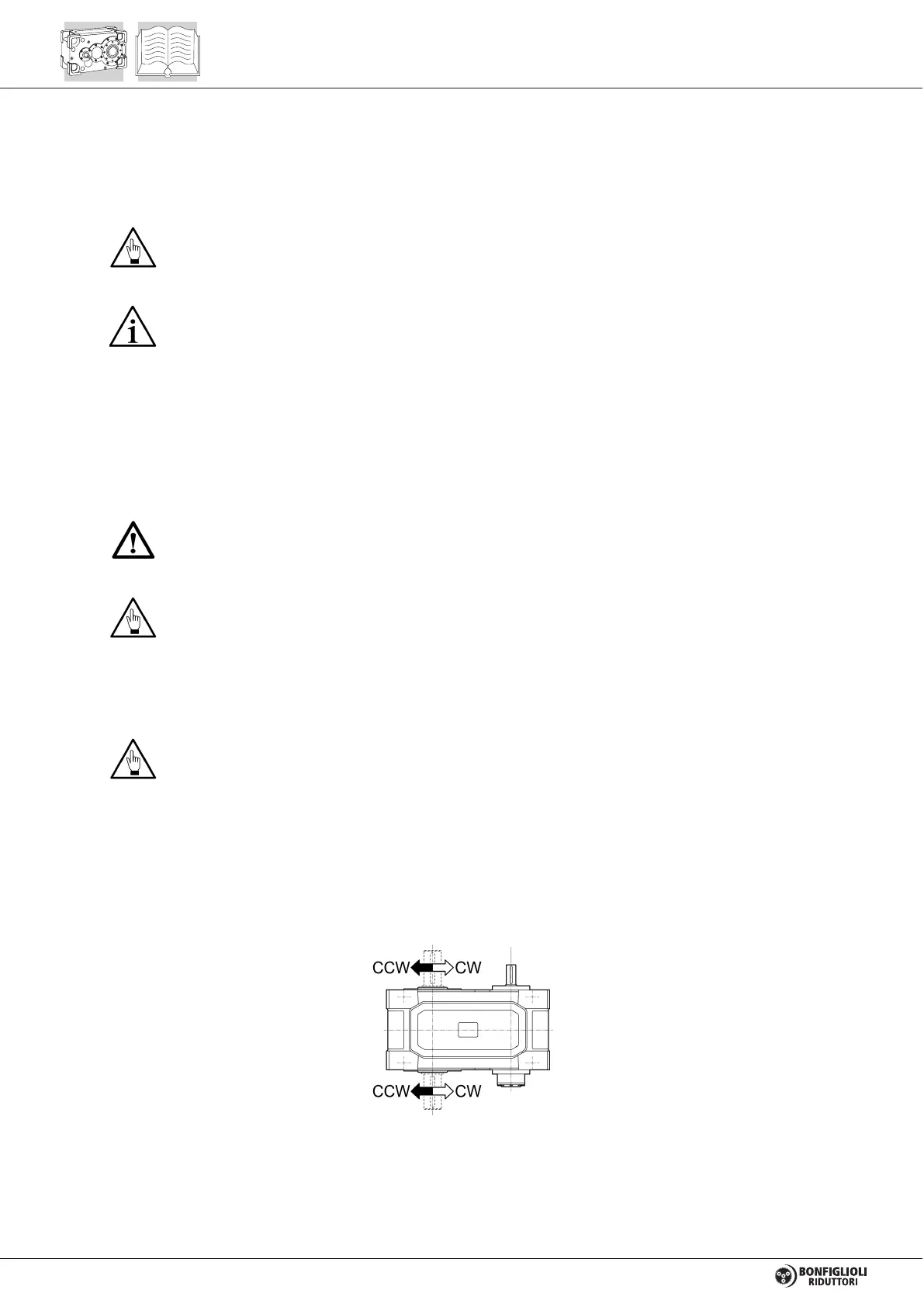

7.3 BACKSTOP DEVICE

The backstop device supplied on request assures that the gear unit only turns in one direction and

prevents reverse drive caused by the load applied to the output shaft.

In certain cases the torque transmittable by the backstop device can be limited with

respect to the torque transmitted by the gear unit. Consult the sales catalogue for detailed

information on this subject.

To avoid damaging the backstop device or the gear train it is essential to prevent the

motor from rotating in the inhibited direction of the transmission.

Before commissioning the unit ensure that the output shaft can be freely turned in the required

direction of travel without having to apply excessive force.

The inhibited direction of the backstop device can be changed by turning the cage. If you wish

to change the inhibited rotation direction, first contact the BONFIGLIOLI RIDUTTORI sales service for

information on the correct procedure to adopt.

The backstop device consists of a freewheel with centrifugal throwout sprags.

To guarantee correct operation of the backstop the gear unit should be driven at a speed of n

1

min

-1

, for slower speeds consult the Bonfiglioli sales service.

The backstop is keyed to the end of the input shaft opposite the drive side and is accessible from the

exterior for inspection. The backstop is mounted to the gear unit by means of a connecting flange and

it shares the same lubricating oil with the gear unit.

30

Loading...

Loading...