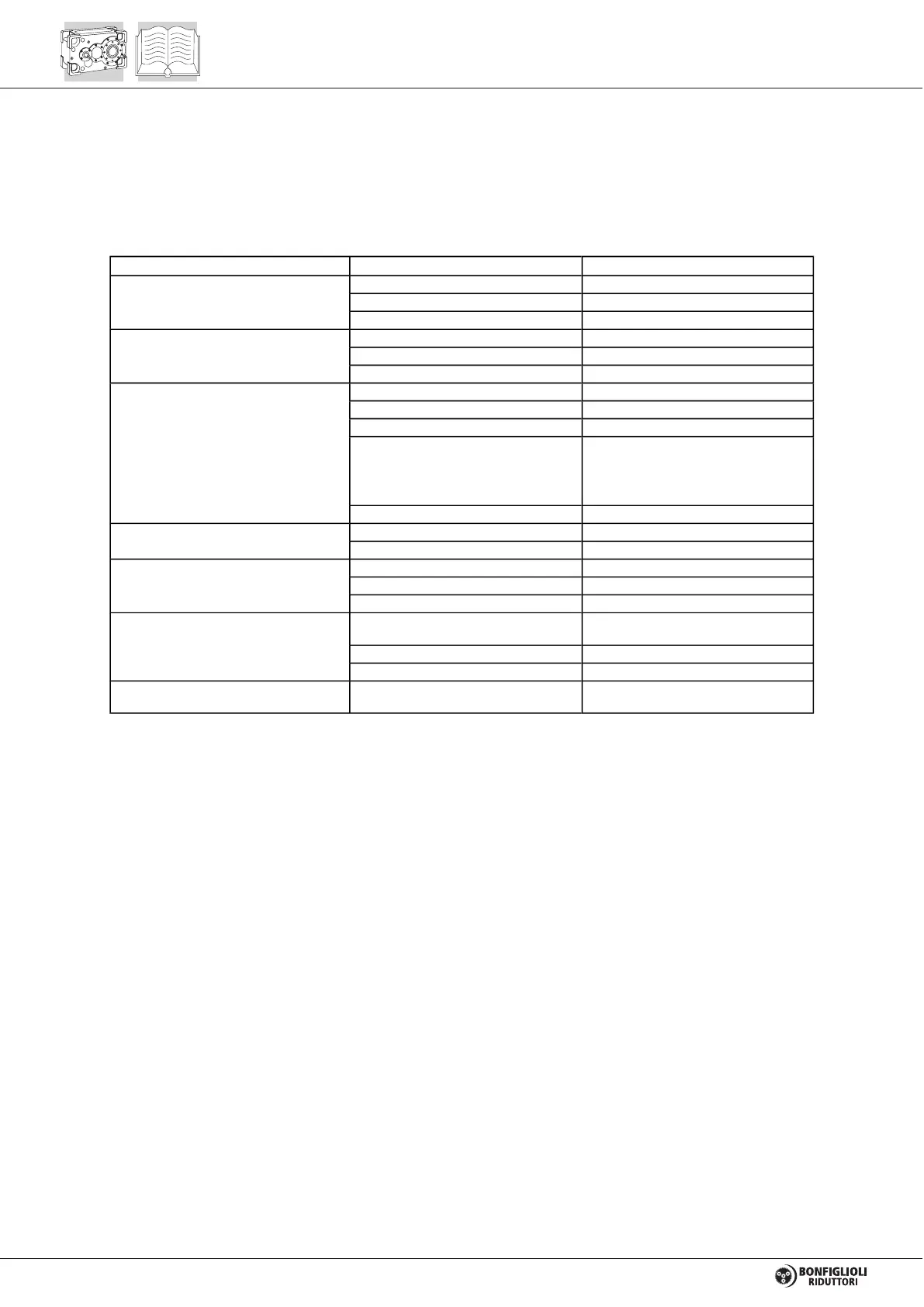

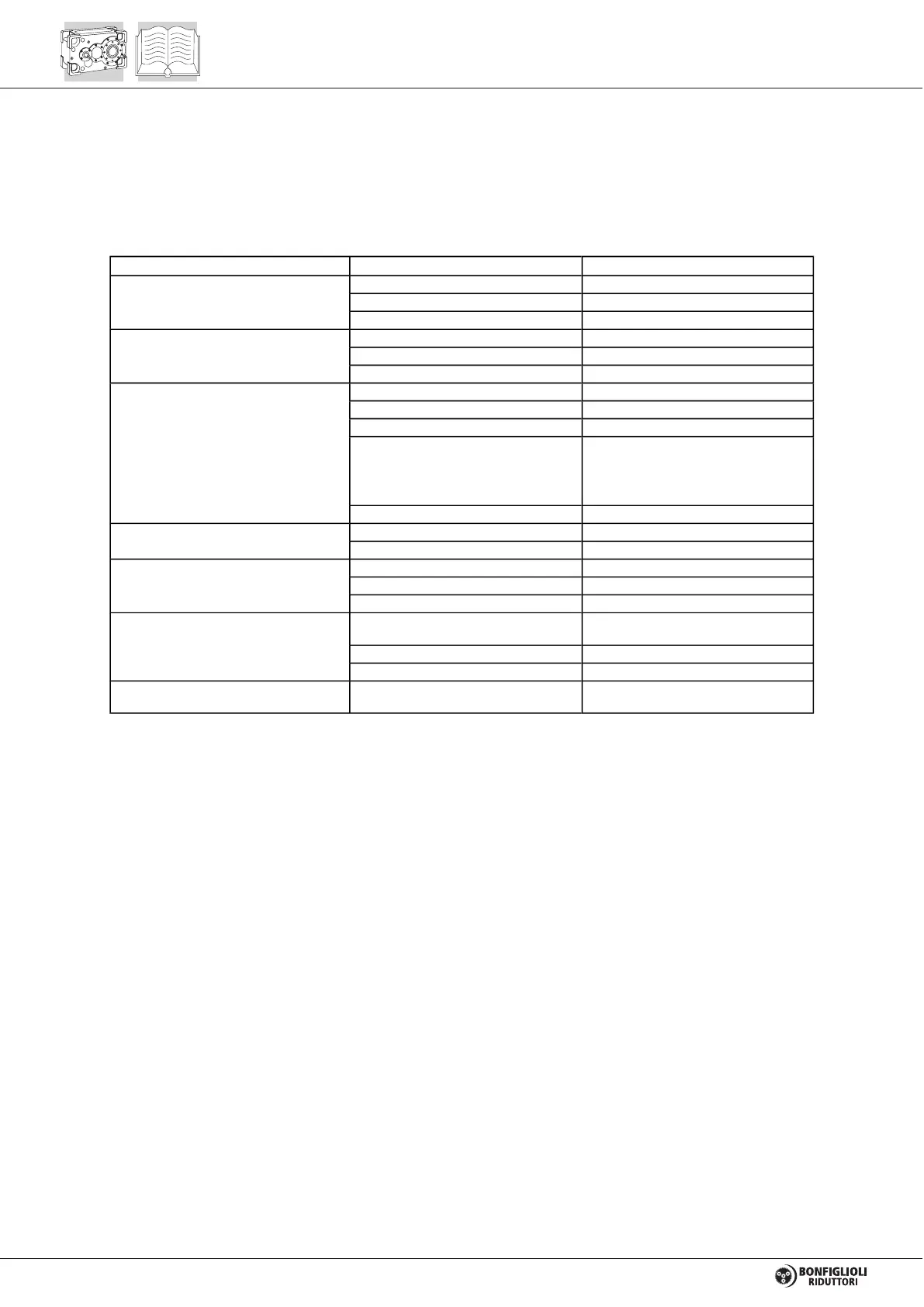

9 TROUBLESHOOTING

The following information is intended to serve as an aid in identifying and correcting defects and faults.

In some cases, such problems may be caused by the plant or machine onto which the gear unit is

assembled, and hence, the cause and eventual solution can be found in the Manufacturer’

documentation for the machine/plant in question.

Bearing temperature too high

Oil level too low Top up oil level

Oil too old Replace oil

Defective bearings Contact authorised workshop

Operating temperature too high

Oil level too high Check oil level

Oil too old Replace oil

Impurities in oil Replace oil

Abnormal running noise

Gears damaged Contact authorised workshop

Bearing axial backlash too high Contact authorised workshop

Bearings defective or worn Contact authorised workshop

Service load too high

Correct service load to nominal values

given in Sales Catalogue

Impurities in oil Replace oil

Abnormal noise at gear unit mounting

Mounting bolts loose Tighten down to specified torque

Mounting bolts worn Replace bolts

Oil leaks

Oil level too high Check oil level

Casing/coupling seals inadequate Contact authorised workshop

Gaskets worn Contact authorised workshop

Gear unit does not run or runs with

difficulty

Oil viscosity too high

Replace oil (see table of recommended

lubricants)

Oil level too high Check oil level

Service load too high Redesign drive for actual service load

Output shaft does not turn with motor

running

Gears damaged Contact authorised workshop

PROBLEM CAUSE SOLUTION

34

Loading...

Loading...