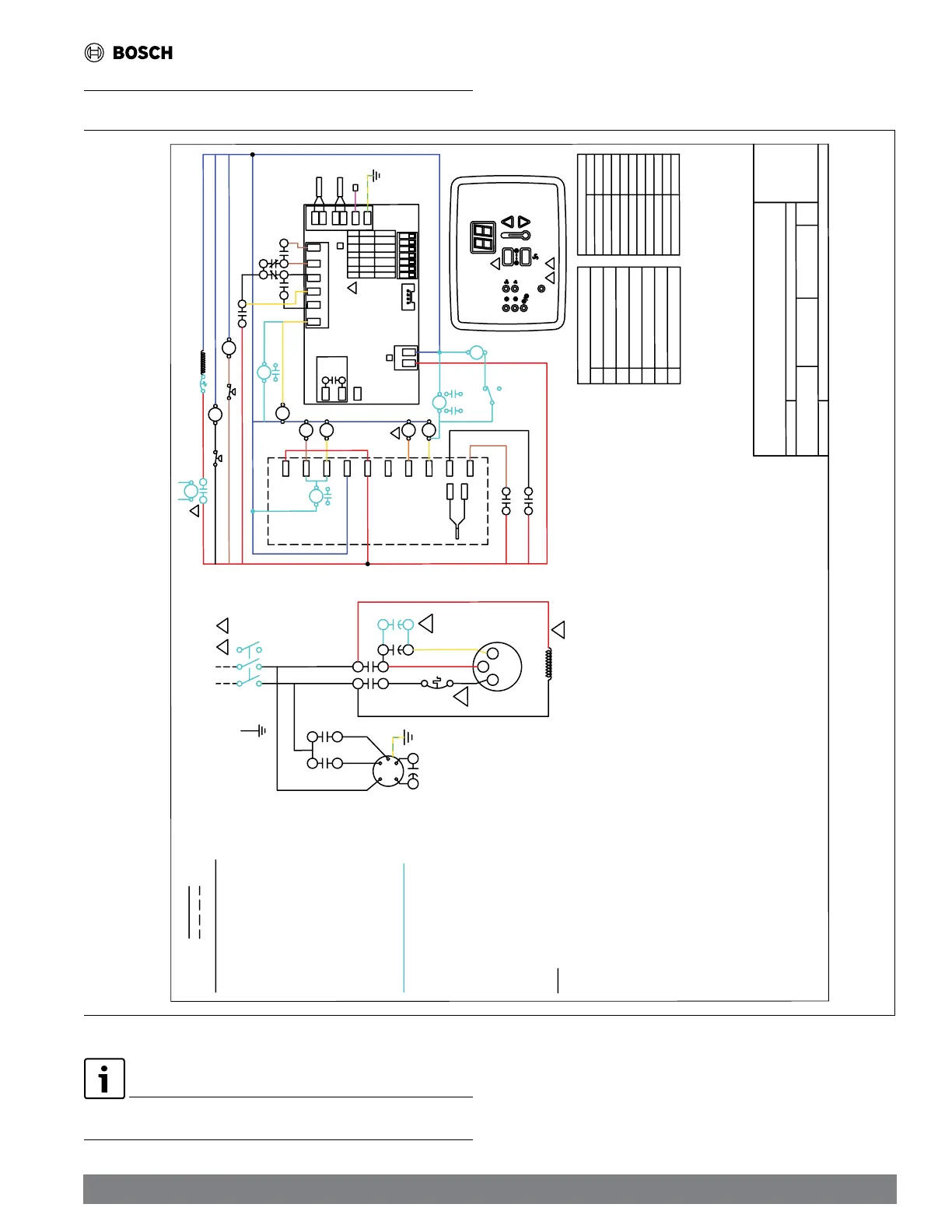

G_Out

G

C

OUT

COM

POWER

UNIT PROTECTION MODULE

STATUS

R

R

ALARM

FREEZE1

FREEZE2

COND

LPCY

HPC

CC

LOCKOUT 2

4

RESET Y R

ALARM PULSE CONT

TEST NO YES

FREEZE1 25F 15F

FREEZE2

25F 15F

PUMP NO YES

GND

SEE NOTES 5-10

LPC

HPC

BK

FS1

WT

FS2

GN/YL

CC

RV

HSR

HPS

HPR

CONTROL

PANEL

R

MALF

C

COMP

REV

LPS

HPS

THERMISTOR

HIGH

LOW

L1

LSR

LPR

4 7

CBR

CLASS II POWER SUPPLY

SERVICE

AUTO

COOL

HEAT

LO

HI

FAN

MODE

4 2

EMS

AUX

24VAC BY OTHERS

OFF

ON

DMS

OAD

FACTORY WIRE

FIELD WIRE

NOTES :

1. SEE UNIT NAME PLATE FOR ELECTRICAL RATING

2. ALL FIELD WIRING MUST BE IN ACCORDANCE WITH N.E.C.-N.F.P.A. #70, COPPER

CONDUCTORS ONLY. CONDUCTEURS EN CUIVRE SEULEMENT.

3. 208/230V UNITS ARE FACTORY WIRED FOR 230V OPERATION. FOR 208V OPERATION, REMOVE 240V

LEAD AND CONNECT IT TO 208V. CAP ALL UNUSED LEADS.

4. EXTERNAL OVERLOAD STANDARD ON ALL UNITS EQUIPPED WITH ROTARY COMPRESSORS.

5. FOR ALTERNATE EMS COIL VOLTAGES CONSULT FACTORY.

6. UPM-I INCLUDES BUILT IN: 270-300 SECOND RANDOM START

300 SECOND DELAY ON BREAK

120 SECOND LOW PRESSURE BYPASS

120 SECOND FREEZE PROTECTION BYPASS

7. "TEST" DIP SWITCH REDUCES DELAYS TO 10 SEC WHEN SET TO "YES". MUST BE SET TO "NO" FOR

NORMAL OPERATION.

8. "FREEZE SENSOR" ON CONDENSER WILL BE SET TO 25°F BY DEFAULT. IF 15°F OPERATI

ON IS

REQUIRED, MOVE DIP SWITCH SLIDER TO THE 15°F POSITION.

9. "ALARM OUTPUT" DIP SWITCH MUST BE SET TO "PULSE" IF BLINKING T-STAT SERVICE LIGHT IS

DESIRED.

10. DEFAULT SETTINGS FOR UPM BOARD FROM FACTORY SHOWN. ALSO SEE INSTALLATION MANUAL.

11. ALARM OUTPUT IS NORMALLY OPEN (NO) DRY CONTACT. IF 24 VAC IS NEEDED, CONNECT R FROM

TERMINAL BLOCK TO ALR-COM TERMINAL, 24VAC WILL BE SENSED ON THE ALR-OUT WHEN THE

UNIT IS IN ALARM CONDITION. OUTPUT WILL BE PULSED IF PULSE IS SELECTED.

12. REVERSING VALVES ARE NOT PRESENT IN STRAIGHT COOL UNITS.

13. SERVICE LIGHT WILL BLINK ONCE ON CONTROL PANEL FOR A HIGH PRESSURE LOCKOUT.

14. SERVICE LIGHT WILL BLINK TWICE ON CONTROL PANEL FOR A LOW PRESSURE LOCKOUT.

15. LOCKOUTS CAN BE RESET BY CY

CLING THE CONTROLLER OFF WITH THE (MODE) BUTTON.

16. IF POWER IS CYCLED TO THE UNIT, THE CONTROL PANEL MAY NEED TO BE REPROGRAMMED.

17. "LOCKOUT" DIP SWITCH MUST BE SET TO "2" FOR PROPER SIMULTANEOUS UMC AND UPM

OPERATION.

18. START CAPACITOR WILL BE PRESENT ON SIZE 018.

PROGRAMMING INSTRUCTIONS:

TO PROGRAM THE CONTROLLER'S USER

CONFIGURABLE FEATURES PRESS THE

TEMPERATURE UP AND DOWN ARROW

BUTTONS SIMULTANIOUSLY AND HOLD FOR

5 SECONDS. THIS WILL PUT THE

CONTROLLER IN THE CONFIGURATION MODE.

USE THE (MODE) BUTTON TO SELECT THE

FEATURE TO BE CONFIGURED:

FARENHEIT/CELCIUS (F/C), TEMPERATURE

DIFFERENTIAL, TIME DELAY/NO TIME DELAY

(dE/nd), CYCLING FAN/CONSTANT FAN

(CY/CO).

ONCE THE DESIRED FEATURE IS SELECTED,

USE THE ARROW

BUTTONS TO

ADJUST IT. THE CONTROLLER

WILL REVERT TO

NORMAL OPERATION AFTER 5 SECONDS OF

NO ACTIVITY.

OPTIONAL COMPONENTS LEGEND:

[ ] AUX - AUXILIARY RELAY

(FOR LOOP PUMP, ETC)

[ ] BMR - BLOWER MONITOR RELAY

[ ] CBR - 24 VAC CIRCUIT BREAKER

[ ] CMR - COMPR. MONITOR RELAY

[ ] CMFR- COMPR. MALFUNCTION RELAY

[ ] DS - DISCONNECT SWITCH

[ ] EMS - ENERGY MGMT SYSTEM RELAY

[ ] OAD

- OUTSIDE AIR DAMPER INCLUDES:

- DAMPER MTR (OAD)

- DAMPER SWITCH (DMS)

[ ] SC - COMPRESSOR START CAPACITOR

STANDARD COMPONENTS LEGEND:

BC - BLOWER MOTOR CAPACITOR

BM - BLOWER MOTOR

CC - COMPRESSOR CONTACTOR

CS - CONDENSATE SENSOR

EOVD - EXTERNAL OVERLOAD

FS - FREEZE SENSOR

HPS - HIGH PRESSURE SWITCH

HPR - HIGH PRESSURE RELAY

HSR - HIGH SPEED RELAY (BLOWER MOTOR)

LPS - LOW PRESSURE SWITCH

LPR - LOW PRESSURE RELAY

LSR - LOW SPEED RELAY (BLOWER MOTOR)

RC - COMPRESSOR RUN CAPACITOR

RV - REVERSING VALVE (HEAT PUMPS)

TS - TEMPERATURE SENSOR

Y1R - Y1 CALL RELAY

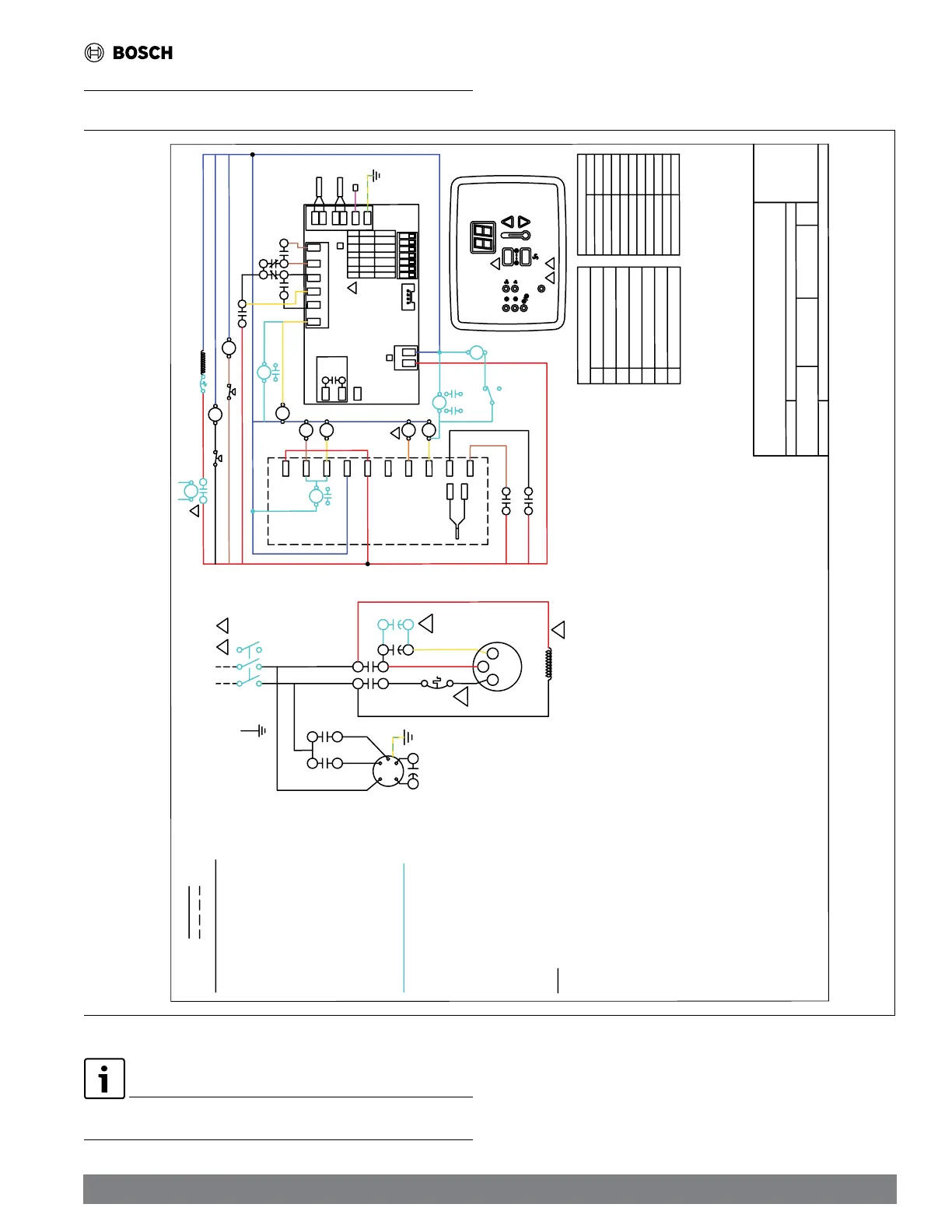

12

13

14

TS

15

5

CMR

CS

BMR

LPR

69

3

Y1R

Y1R

2 4

HPR

4 7

LPS

LPR

HPR

3

96

COLOR CHART LEGEND

BK

BL

GN

OG

VT

RD

WT

BN

BLACK

BLUE

BROWN

GREEN

ORANGE

VIOLET

RED

WHITE

YL

YELLOW

GY

GRAY

ABBREVIATION

COLOR

17

UPM STATUS LED - BLINK CODES

1

HIGH PRESSURE FAULT

2

LOW PRESSURE FAULT

3 CONDENSER FREEZE CONDITION

4 CONDENSATE OVERFLOW FAULT

5

BROWN OUT FAULT

6 EVAPORATOR FREEZE CONDITION

7 REFRIGERANT LEAKAGE

BL

RD

WT

BN

BL

BL

RD

RD

BN

WT

RD

RD

BL

BL

YL

YL

WT

WT

BN

WT

BL

BL

BL

OR

YL

BL

RD

BK

BL

BK

BL

BK

BL

BK

BL

LUG

GROUND

UNIT

GROUND

BLK (COM)

TRANSFORMER

CC

T1

L1

T2

L2

L1 L2

COMP

C

R

S

3

2

1

BC

BM

WT

BK

RD

GN/YL

RC

SC

18

HSR

4

2

LSR

4

2

BK

DS

EOVD

4

LINE VOLTAGE

USE COPPER CONDUCTORS ONLY

RD

YL

BN

BN

YL

WT

WT

BN

Loading...

Loading...