Product information

MS 200 – 6720879925 (2017/11)

25

• If the temperature in the DHW cylinder is less than the required DHW

temperature by the set switch-on temperature differential, the DHW

cylinder is heated up.

Basic primary store system for heating a buffer cylinder for heat

interface units

• If the temperature in the buffer cylinder is less than required in the set

switch-on temperature differential, the buffer cylinder will be heated

up.

• Therm.dis./daily ht cyl1 must be deactivated.

This system is only available with the CR 400/CW 400/CW 800/RC300/

RC310 user interface and is configured via the DHW settings. A DHW

circulation pump can be connected.

2.6 Scope of delivery

Fig. 1 at end of document:

[1] Module

[2] Cylinder temperature sensor (TS2)

[3] Collector temperature sensor (TS1)

[4] Bag with strain relief

[5] Installation instructions

2.7 Declaration of Conformity

The design and operating characteristics of this product comply with the

European and national requirements.

The CE marking declares that the product complies with all the

applicable EU legislation, which is stipulated by attaching this

marking.

The complete text of the Declaration of Conformity is available on the

Internet: www.bosch-thermotechnology.com.

2.8 Specifications

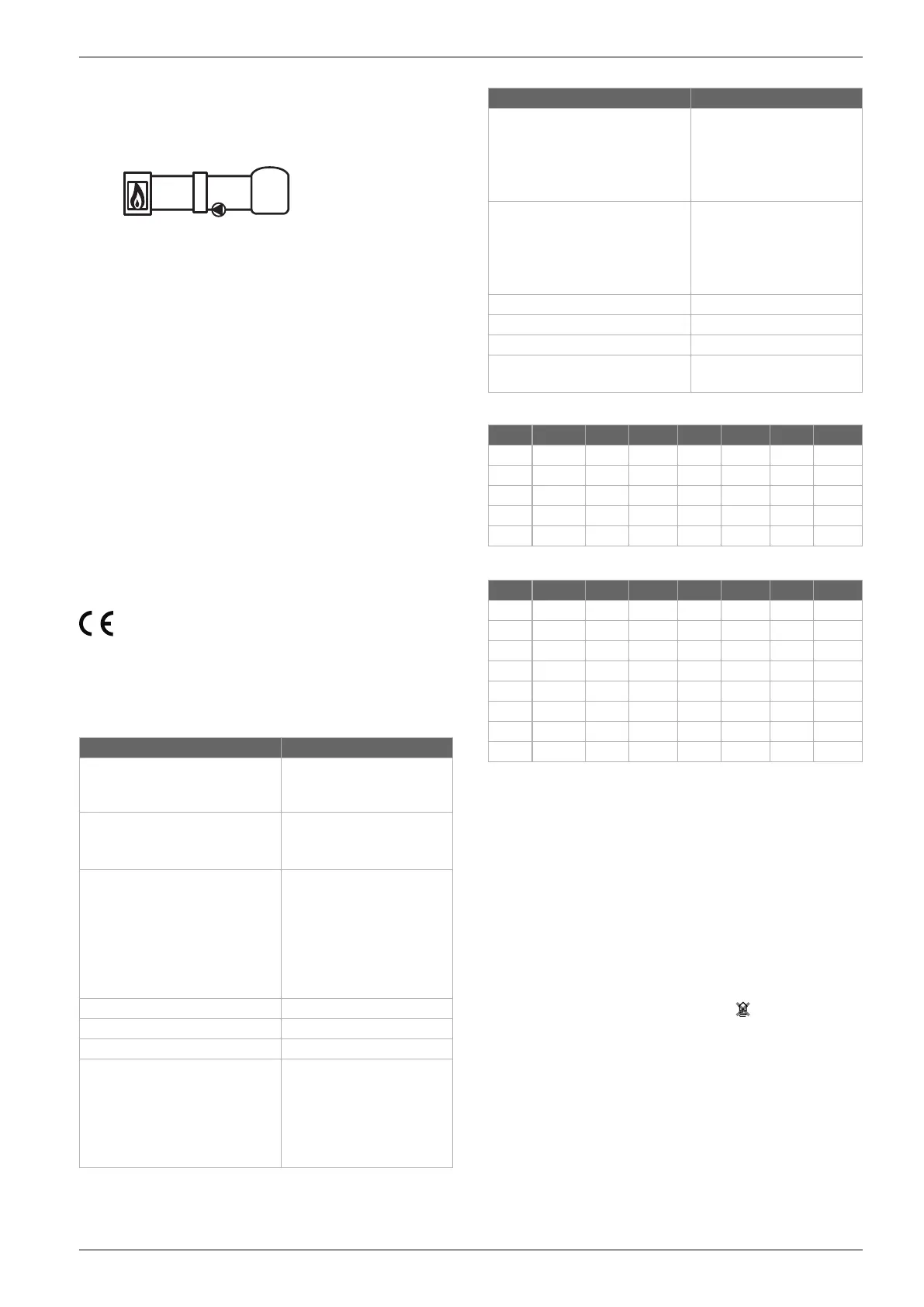

Table 2

Table 3 Temperature sensor measurements (TS2 - TS6, TS8 - TS20)

Table 4 Measurements, collector temperature sensor (TS1 / TS7)

2.9 Additional accessories

For precise information regarding suitable accessories, refer to

manufactures website.

• For solar thermal system 1:

– Solar pump; connection to PS1

– electronically regulated pump (pulse width modulation or or

0-10 V); connection to PS1 and OS1

– Temperature sensor (1st collector array); connection to TS1

(Scope of delivery)

– Temperature sensor at the bottom of the 1st cylinder; connection

to TS2 (scope of delivery)

• Additionally for central heating backup (A) ( ):

– 3-way valve; connection to VS1/PS2/PS3

– Temperature sensor in the middle of the 1st cylinder; connected

to TS3

– Temperature sensor situated at the return; connection to TS4

• Additionally for 2nd cylinder/swimming pool with valve (B):

– 3-way valve; connection to VS2

– Temperature sensor at the 2nd cylinder, at the bottom;

connection to TS5

Specifications

Dimensions (W × H × D) 246 × 184 × 61 mm (further

dimensions Illustration 2 at

the end of this document)

Maximum conductor cross-section

• 230 V terminal

• Extra-low voltage terminal

• 2.5 mm

2

• 1.5 mm

2

Rated voltages

• BUS

• Module mains voltage

• HMI

• Pumps and mixers

• 15 V DC (reverse-polarity-

protected)

• 230 V AC, 50 Hz

• 15 V DC (reverse-polarity-

protected)

• 230 V AC, 50 Hz

Fuse 230 V, 5 AT

BUS interface EMS 2/EMS plus

Power consumption on – standby < 1 W

Maximum output

Maximum output per connection

• PS1; PS4; PS5; VS1/PS2/PS3

• VS2

1100 W

• 400 W (high-efficiency

pumps permissible;

<30 A for 10 ms)

• 10 W

0010015813-001

Cylinder temperature sensor

measuring range

• Lower fault limit

• Display area

• Upper fault limit

• < – 10 °C

• 0 ... 100 °C

• > 125 °C

Capturing range, collector

temperature sensor

• Lower fault limit

• Display area

• Upper fault limit

• < – 35 °C

• – 30 ... 200 °C

• > 230 °C

Permitted ambient temp. 0 ... 60 °C

Protection IP 44

Protection class I

ID no. Data plate ( Fig. 19 at the

end of document)

°C °C °C °C

20 14772 45 5523 70 2332 95 1093

25 12000 50 4608 75 1990 100 950

30 9786 55 3856 80 1704 – –

35 8047 60 3243 85 1464 – –

40 6653 65 2744 90 1262 – –

°C °C °C °C

– 30 364900 25 20000 80 2492 150 364

– 20 198400 30 16090 90 1816 160 290

– 10 112400 35 12800 95 1500 170 233

0 66050 40 10610 100 1344 180 189

5 50000 50 7166 110 1009 190 155

10 40030 60 4943 120 768 200 127

15 32000 70 3478 130 592 – –

20 25030 75 2900 140 461 – –

Specifications

Loading...

Loading...