Pack201 | Operator Instructions | Section 3

EN | 4

© Bosch Packaging Technology, Inc.

All rights reserved 2012

3.2 During Production

During production, periodically examing the following

items�

Examine both the endseals of the packages. If the seal

is not correct:

• Check the crimper temperature setting�

• Check for dirty crimpers

• Check the crimper clearance�

• Check the crimper pressure�

Examine the longitudinal seal on the package. If the

seal is not correct:

• Check the nwheel temperature setting.

• Check for dirty nwheels.

• If package is too loose, adjust the cant on the rst

nwheel assembly.

• If the lm edges are not even, turn the centering

knob to adjust�

Examine the lm ow into and out of the former/fold-

ing box. If lm is not owing properly:

• Check to make sure the material is centered and

remains mated properly in the former�

• Check the position of the inclination arm and

roller on the backstand�

• Check position and alignment of the former wings�

Prepare Second Film Roll

1� Mount the second lm roll on the backstand, if

equipped�

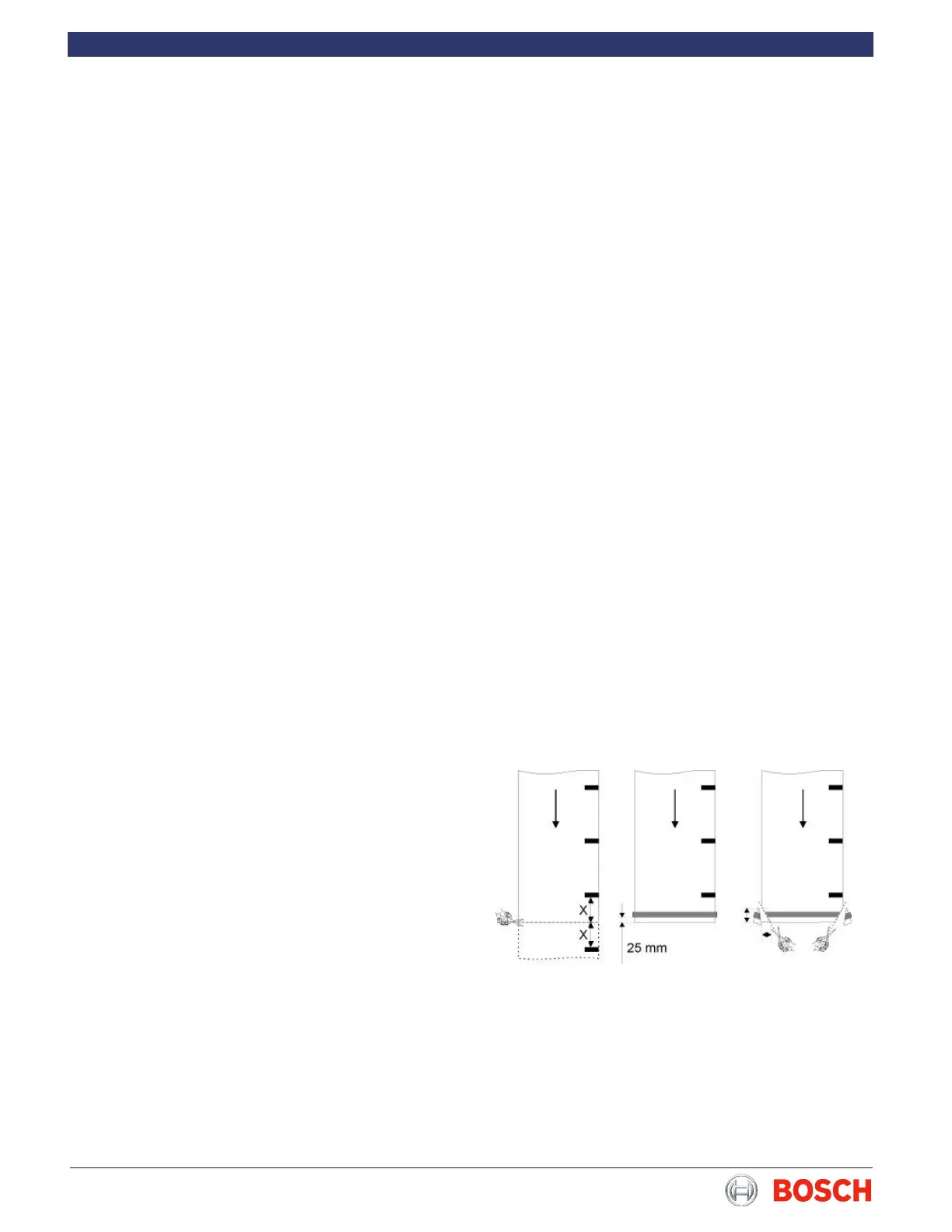

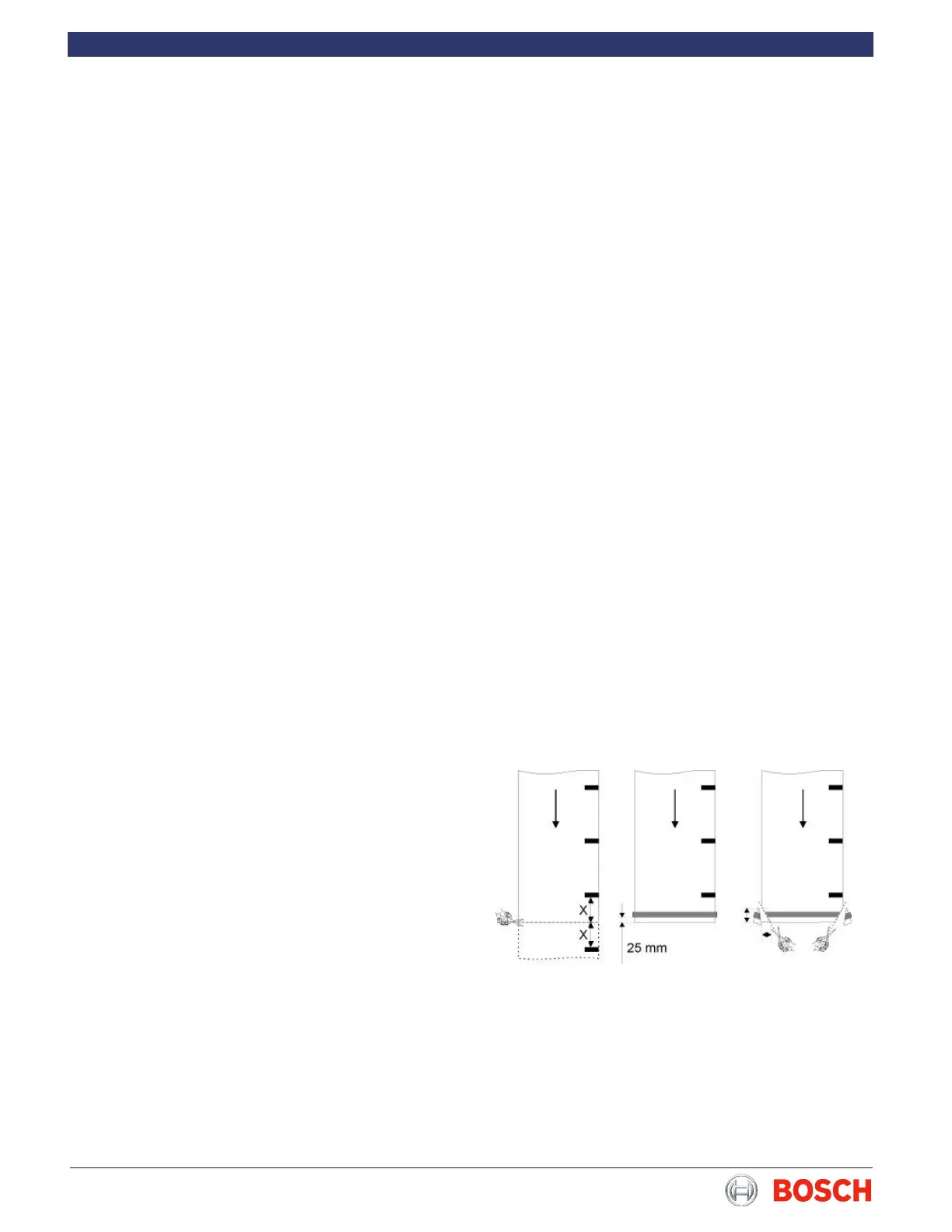

2� Unroll some lm until two registration marks can

be seen�

3� Cut the lm halfway between the two marks.

4� Apply double-sided tape 25 mm from the cut end

of the lm.

5� Trim off the corners of the lm.

6� Attach the new lm to the end of the old lm so

that the registration marks align�

Loading...

Loading...