English–121 619 P03 456 • (05.11) PS

Hand Placement

Keep hands, fingers and arm away from the rotating

saw blade.

Hold the work piece securely with both hands and

press it firmly against the saw table, especially when

working without a fence or guide.

(see Figures and )

Use the pusher piece provided for small work pieces

(see Figure ) and, when sawing with a vertical bev

el angle, the auxiliary parallel fence 22. (see

Figure )

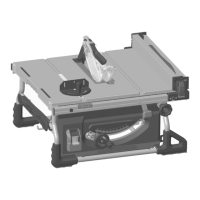

Maximum Work Piece Dimensions

Sawing

Set the required vertical bevel angle and/or horizontal

mitre angle as well as the parallel fence.

Place the work piece on the saw table in front of the

protective hood 5.

Raise or lower the saw blade with the crank 14 far

enough so that the saw teeth extend approx. 1 mm

above the surface of the work piece.

Switch on the electrotool.

Guide the work piece slowly against the protective

hood. The protective hood is formed so that it glides

by itself over the edge of the work piece. The side pro

tector 68 provides additional protection for vertical

bevel angles (see Figure

).

Saw through the work piece with uniform feeding.

Switch off the electrotool and wait until the saw blade

comes to a complete standstill.

Sawing Horizontal Mitre Angles

(

Also see Figure

)

Set the required horizontal mitre angle.

Place the work piece against the profile 49 so that the

desired cutting line is aligned with the marking on the

yellow point.

The profile should not extend beyond the cutting line.

In this case, loosen the knurled nut 66 and slide back

the profile.

Switch on the electrotool.

Press the work piece with one hand against the stop

fence and slide the angle guide with the other hand on

the locking knob

57

slowly forward in the guide groove

7

.

Replacing the Table Insert

The red insert plate 3 can become worn after long use

of the electrotool.

Replace a defective insert plate.

Place the electrotool in the transport position.

Swing the protective hood 5 to the rear to the stop.

Lift the insert plate 3 at the front with a commercially

available screwdriver and remove it from the tool well.

Mount the new insert plate.

(See the Section "Mounting the Table Insert")

Return the protective hood 5 to the lowered position.

Turn the crank 14 slowly in the clockwise direction until

the saw blade reached the desired working position

(upper saw teeth approx. 1 mm above the surface of

the work piece).

Checking and Adjusting Basic

Adjustments

Before all work on the machine, pull the mains

plug.

To ensure precise cuts, the basic adjustments must be

checked and adjusted as necessary after intensive us

age.

Vertical Standard Bevel Angles (0°, 45°)

Place the power tool in the working position.

Set the vertical bevel angle to 0°.

Swing back the protective hood 5 to the stop.

Checking: (see Figure

)

Place a combination square set to 90° on the saw ta

ble 1. The leg of the square must be flush with the saw

blade over its entire length.

Adjusting: (see Figure )

Loosen the screw 29 with which the 0° stop 28 can be

shifted.

Loosen the locking lever 15. Slide the hand wheel 27

against the 0° stop until the leg of a combination

square is flush with the saw blade over its entire length.

Hold the hand wheel in this position and tighten the

locking lever 15. Retighten the screw 29.

In case the angle indicator 61 is not aligned with the 0°

mark on the scale 69, loosen the screw 70 with a com

mercially available Phillips screwdriver and align the

angle indicator with the 0° mark.

Repeat the above listed steps in a corresponding

manner for the vertical bevel angle of 45° (loosen the

screw 25, adjust the 45° stop 26). The angle indicator

61 should not be readjusted again in the process.

Vertical Bevel Angle Maximum Height of the

Work Piece

0° 79 mm

45° 64 mm

Q1 Q2

R1

R2

P

Q2

S1

S2

GTS10_WEU.book Seite 12 Mittwoch, 2. November 2005 2:05 14

Loading...

Loading...