English–91 619 P03 456 • (05.11) PS

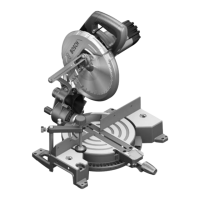

Mounting the Auxiliary Parallel Fence

(see Figure )

Insert the attachment screws 47 through the drillings

on the side of the parallel fence. The heads of the

screws serve for the positioning of the auxiliary parallel

fence.

Slide the auxiliary parallel fence over the heads of the

attachment screws.

Place the washers 46 on the attachment screws,

screw on the wing nuts 45 and tighten.

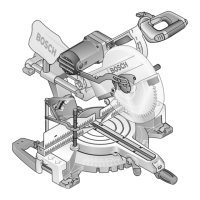

Mounting the Angle Guide

Insert the rail 48 of the angle guide 9 into one of the

guide groove 7 provided on the saw table.

(see Figure )

For better support of long work pieces, the angle guide

can be widened with the profile 49.

As required, mount the profile to the angle guide with

the attachment set 50 provided. (see Figure

)

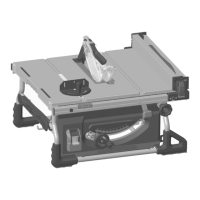

Stationary Mounting

(see Figure

)

To ensure safe handling, the power tool

must be mounted on a flat and stabile

working surface (e.g., workbench).

Attach the power tool with suitable screw fasteners to

the working surface. The holes 13 serve for this pur

pose.

5 OPERATING INSTRUCTIONS

Changing the Tool

Before all work on the machine, pull the mains

plug.

Select a saw blade suitable for the material to be

worked.

Use only saw blades whose allowable rotational speed

is as least as high as the noload speed of the power

tool.

Use only saw blades that comply with the characteris

tic data given in these operating instructions and have

been tested according to EN 8471 and appropriately

marked.

Take care when changing the saw blade that the tooth

offset is wider and the main body of the saw blade is

thinner than the thickness of the riving knife.

Removing the Saw Blade

Place the power tool in the transport position.

(See Section "Mounting the Table Insert")

With a commercially available screwdriver, pry up the

table insert 3 at the front (see Figure ) and remove

it from the tool well.

Place the power tool in the working position.

(See Section "Mounting the Protective Hood")

Swing back the protective hood 5 to the stop.

Turn the hexnut 54 with the ring spanner 51 (23 mm)

provided and pull the spindle lock 52 at the same time

until it engages. (see Figure )

Hold the spindle lock pulled and unscrew the hexnut

54 in the counter clockwise direction.

Take off the clamping flange 53. Remove the saw

blade 6. (see Figure )

Mounting the Saw Blade

If necessary, clean all parts to be mounted.

Place the new saw blade on the tool spindle 55.

(see Figure )

When mounting, observe that the cutting

direction of the saw teeth (arrow on the

saw blade) agrees with the direction of the

arrow on the protective hood!

Place on the clamping flange 53 and the hexnut 54.

Pull the spindle lock 52 until it engages and tighten the

hexnut 54 in the clockwise direction with a tightening

torque of approx. 15 23 Nm.

Reinsert the table insert plate 3.

Swing the protective hood 5 back down.

Dust/Chip Extraction

Take protective measures when dust is pro>

duced while working that can be detrimental to

health, combustible or explosive. For example,

some dusts are considered carcinogenic. Wear a dust

protection mask and use dust/chip extraction, if it can

be connected.

External Dust Extraction

Use a suitable adapter from the Bosch accessory pro

gram to connect a vacuum cleaner to the sawdust

ejector 35. Firmly attach the adapter and vacuum

cleaner hose.

The vacuum cleaner must be suitable for the material

to be worked.

When vacuuming dry dust that is especially detrimen

tal to health or carcinogenic, use a special vacuum

cleaner.

E

F

G

H

I1

I2

I3

I3

GTS10_WEU.book Seite 9 Mittwoch, 2. November 2005 2:05 14

Loading...

Loading...