RE 92650/2020-03-03, Bosch Rexroth AG

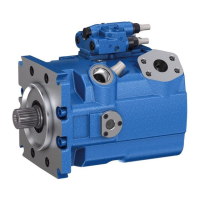

23 Axial piston variable pump | A1VO Series 10

Installation instructions

1) Because complete air bleeding and filling are not possible inthis

position, the pump should beair bled and filled inahorizontal

position before installation.

Installation instructions

General

The axial piston unit must befilled with hydraulic fluid and

air bled during commissioning and operation. This must

also beobserved following alonger standstill astheaxial

piston unit may empty viathehydraulic lines.

Particularly with the "drive shaft up/down" installation

position, filling and air bleeding must be carried out

completely as there is, for example, adanger ofdry

running.

The leakage in the pump housing must be discharged tothe

reservoir via the highest available tank port (L

1

, L

2

).

For combinations ofmultiple units, the leakage fluid must

be drained off at each pump.

If ashared drain line isused for several units, make sure

that therespective case pressure ineach unit isnot

exceeded. The shared drain line must bedimensioned

toensure that themaximum permissible case pressure

ofall connected units isnot exceeded inany operating

conditions, particularly atcold start. If this isnot possible,

separate drain line must belaid, ifnecessary.

To achieve favorable noise values, decouple all connecting

lines using elastic elements and avoid above-reservoir

installation.

Inall operating conditions, the suction lines and the drain

lines must flow into the reservoir below the minimum fluid

level. The permissible suction heighth

S

results from the

total pressure loss. However, it must not behigher than

h

Smax

=

800 mm. The minimum suction pressure

atportSmust also not fall below 0.8bar abs. during

operation and during acold start.

When designing the reservoir, ensure adequate distance

between the suction line and the case drain line. This

prevents theheated return flow from being drawn directly

back into thesuction line.

Notice

Incertain installation positions, an influence

ontheadjustment orcontrol can beexpected. Gravity,

dead weight and case pressure can cause minor

characteristic shifts and changes inactuating time.

For key, see page 24.

Installation position

See thefollowing examples 1 to11.

Further installation positions are available upon request.

Recommended installation position: 1 and 2

Below-reservoir installation (standard)

Below-reservoir installation means that theaxial piston unit

isinstalled outside ofthereservoir below theminimum

fluid level.

Installation position Air bleed Filling

1

S

F

SB

h

h

L

F, L

1

L

1

2

S

L

2

SB

h

t min

h

min

F

F, L

2

L

2

3

S

L

1

SB

h

t min

h

min

F

F, L

1

or L

2

L

1

or L

2

4

1)

L

2

SB

h

t min

h

min

F, L

1

or L

2

L

1

or L

2

Loading...

Loading...