RE 92650/2020-03-03, Bosch Rexroth AG

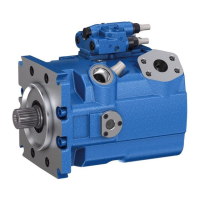

25 Axial piston variable pump | A1VO Series 10

Project planning notes

Project planning notes

▶ The A1VO axial piston variable pump isdesigned tobe

used inopen circuit.

▶ The project planning, assembly and commissioning

oftheaxial piston unit require theinvolvement

ofqualified skilled persons.

▶ Before using theaxial piston unit, please read

thecorresponding instruction manual completely and

thoroughly. If necessary, this can berequested from

BoschRexroth.

▶ Before finalizing your design, please request abinding

installation drawing.

▶ The specified data and notes contained herein must

beobserved.

▶ Depending ontheoperating conditions oftheaxial

piston unit (working pressure, fluid temperature),

thecharacteristic curve may shift.

▶ The characteristic curve may also shift duetothe dither

frequencyorcontrol electronics.

▶ Preservation: Our axial piston units are supplied

asstandard with preservative protection foramaximum

of12 months. If longer preservation isrequired

(maximum 24 months), please specify this inplain text

when placing your order. The preservation periods apply

under optimal storage conditions, which can befound

indatasheet90312orinthe instruction manual.

▶ Not all versions oftheproduct are approved foruse

inasafety function according toISO13849. Please

consult theproper contact atBoschRexroth ifyou

require reliability parameters (e.g. MTTF

d

)

forfunctionalsafety.

▶ Depending onthe type ofcontrol used, electromagnetic

effects can beproduced when using solenoids. Use

ofthe recommended direct current (DC) onthe

electromagnet does not produce any electromagnetic

interference (EMI) nor isthe electromagnet influenced

byEMI. Potential electromagnetic interference (EMI)

exists ifthe solenoid isenergized with amodulated

direct current (e.g. PWM signal). The machine

manufacturer should conduct appropriate tests and take

appropriate measures toensure that other components

oroperators (e.g. with apacemaker) are notaffected

bythis potentiality.

▶ Pressure controllers are notsafeguards against pressure

overload. Be sure toadd apressure relief valve tothe

hydraulic system.

▶ For drives that are operated foralong period with

constant rotational speed, thenatural frequency

ofthehydraulic system can bestimulated

bytheexcitation frequency ofthepump

(rotationalspeed frequency ×9). This can beprevented

with suitably designed hydraulic lines.

▶ Please note thedetails regarding thetightening torques

ofport threads and other threaded joints inthe

instruction manual.

▶ Working ports:

– The ports and fastening threads are designed forthe

specified maximum pressure. The machine orsystem

manufacturer must ensure that theconnecting

elements and lines correspond tothe specified

application conditions (pressure, flow, hydraulic

fluid, temperature) with thenecessary safety factors.

– The working ports and function ports are only

intended toaccommodate hydraulic lines.

Loading...

Loading...