The Rexroth IndraDrive M HMD01 is a power section drive controller designed for use in industrial electric drive and control systems. This operating instruction manual, DOK-INDRV*-HMD01******-IT01-EN-P, Edition 01, provides comprehensive information on its installation, operation, and maintenance.

Function Description

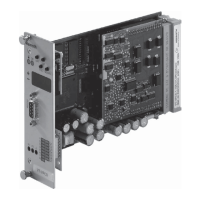

The HMD01 power section is a key component of the Rexroth IndraDrive M system, designed to control connected motors. It operates in conjunction with listed DC power supply units, such as the HMV series, which provide the necessary input current. The drive controller manages motor power connections, motor temperature monitoring, and motor holding brakes. It features two inverter outputs, which are coded to prevent accidental interchanging of cables, ensuring correct connections for X5.1 and X5.2 motor connections. The device also includes connections for a 24V supply, DC bus, equipment grounding conductor, and shield connections for control lines and motor cables.

Important Technical Specifications

The HMD01 series includes models such as HMD01.1N-W0012, HMD01.1N-W0020, and HMD01.1N-W0036, with varying effective peak currents. Key specifications include:

- UL Listing: UL 508 C, CSA C22.2 No. 14-10, UL files E 134201.

- Pollution Degree (UL): 2.

- Ambient Temperature (UL): Nominal data: 40 °C; Reduced nominal data: 55 °C.

- Mass: Ranges from 5.50 kg (HMD01.1N-W0012) to 7.50 kg (HMD01.1N-W0036).

- Dimensions (UL): Height: 440 mm; Depth: 262 mm; Width: 50 mm (HMD01.1N-W0012, HMD01.1N-W0020) or 75 mm (HMD01.1N-W0036).

- Minimum Spacing: Top: 80 mm; Horizontal: 0 mm; Bottom: 100 mm.

- Rated Control Voltage Input (UL): 24 V ± 20%.

- Rated Power Consumption Control Voltage Input (UL): 17 W (HMD01.1N-W0012, HMD01.1N-W0020) or 11 W (HMD01.1N-W0036).

- Short Circuit Current Rating (SCCR): 42000 A rms.

- Rated Input Voltage, Power (UL): DC 254-750 V.

- Rated Input Current (UL): Ranges from 17.0 A (HMD01.1N-W0012) to 49.0 A (HMD01.1N-W0036).

- Output Voltage (UL): 3 x AC 0-530 V.

- Output Current (UL): Ranges from 6.9 A (HMD01.1N-W0012) to 20.0 A (HMD01.1N-W0036).

- Field Wiring Material: Cu; 60/75 °C; 1.

- Output Frequency Range (UL): 0-800 Hz.

- Power Dissipation (continuous current and DC bus power): Ranges from 2 x 95 W (HMD01.1N-W0012) to 2 x 205 W (HMD01.1N-W0036).

- Degree of Protection: IP 20.

- Connection Cable (Motor): Solid wire: 0.5-1.5 mm²; Stranded wire: 0.5-1.5 mm² (AWG 20-16).

- Current Carrying Capacity (X6.3, X6.4): 1.5 A per axis.

- Time Constant of Load (X6): 50 ms.

- Switching Frequency (X6): 0.5 Hz.

- DC Bus Connection Current Carrying Capacity: With contact bars -072: 220 A; Additionally with contact bars -042 and end piece: 245 A.

- DC Bus Line Cross Section: Min. 10 mm², but not smaller than supply feeder cross section.

- DC Bus Line Dielectric Strength: ≥ 750 V (e.g., strand type - H07).

- Maximum Allowed Inductance (DC Bus): 100 μH (2 twisted single strands, 75 m long).

Usage Features

The HMD01 drive controllers are designed for industrial applications, adhering to IEC 60204-1 and NFPA 79 standards. They are products of category C3 (with limited availability) according to IEC 61800-3, requiring suitable line filters to maintain this category.

Installation:

- Safety: The device must be operated only by qualified personnel, with all safety instructions read and understood. It requires a permanently installed equipment grounding conductor.

- EMC Measures: Optimal EMC installation involves spatial separation of interference-free, interference-susceptible, and strongly interference-susceptible areas within the control cabinet. Signal, mains, and motor lines should be routed separately with a minimum distance of 10 cm, or with separating sheets. Cable shields must be connected to ground over a large surface area at both ends for digital signals, and at one end for analog signals.

- Cooling: Proper cooling is critical. Devices with high power dissipation should be placed in the top line of the control cabinet, near the outlet air aperture. Air guides are recommended between lines to protect against warm air and dripping liquids. Cooling units should be positioned to prevent condensation water from dripping onto devices.

- Connections: All connections, including motor, 24V supply, DC bus, and grounding, must be made according to the wiring diagrams and technical specifications provided in the manual. Special attention is given to the coding of motor connectors X5.1 and X5.2 to prevent incorrect connections.

Operation:

- Dangerous Movements: The system's monitoring functions are generally sufficient to prevent malfunctions, but additional installation-side monitoring and higher-level, fail-safe measures are necessary for personal safety, especially concerning dangerous movements. Emergency stopping switches must be readily accessible and verified before commissioning.

- Hot Surfaces: Metallic surfaces, such as heat sinks, can reach temperatures above 60 °C (140 °F) during or after operation. A cooling-down period of at least 15 minutes (up to 140 minutes for motors) is required before touching.

- Electrical Safety: Before accessing electrical parts with voltages above 50 V, the power supply must be disconnected, and capacitors must be allowed to discharge for at least 30 minutes. Voltage must be checked to ensure it has fallen below 50 V before touching.

Maintenance Features

- Battery Safety: Batteries contain active chemicals and require careful handling. They should not be reactivated, recharged, thrown into open flames, or dismantled. Only specified battery types should be used. Used batteries must be disposed of separately according to national regulations.

- Troubleshooting: The manual provides documentation for troubleshooting, including parameter descriptions and guides for various firmware versions.

- Service and Support: Bosch Rexroth AG offers worldwide service and support, including a 24/7 helpdesk. When contacting support, users should provide a detailed description of the malfunction, type plate information (type codes and serial numbers), and contact data.

- Environmental Protection and Disposal: Products are designed for re-use and recycling. They do not contain hazardous substances that would be released during normal use. Most components, particularly metals, can be recycled. Packaging materials are also recyclable. Products can be returned to Bosch Rexroth AG for disposal, provided they are free of oil, grease, or foreign materials. Electronic modules and plastic parts containing flame retardants require special separation processes for recycling.

Loading...

Loading...