MAINTENANCE

GENERAL INFORMATION

Regular maintenance is the key to long equipment life and safe operation. Maintenance

requirements have been reduced to an absolute minimum. However, it is very important that

these maintenance functions be performed as described below.

WARNING! Avoid serious injury. Lower the stump grinder to the ground, set the park-

ing brake, stop the skid steer engine and remove the key before leaving the

operator's seat. If unit must be left raised for maintenance block the unit

securely to prevent accidental release of the lifting mechanism. Disconnect

the hydraulic couplers.

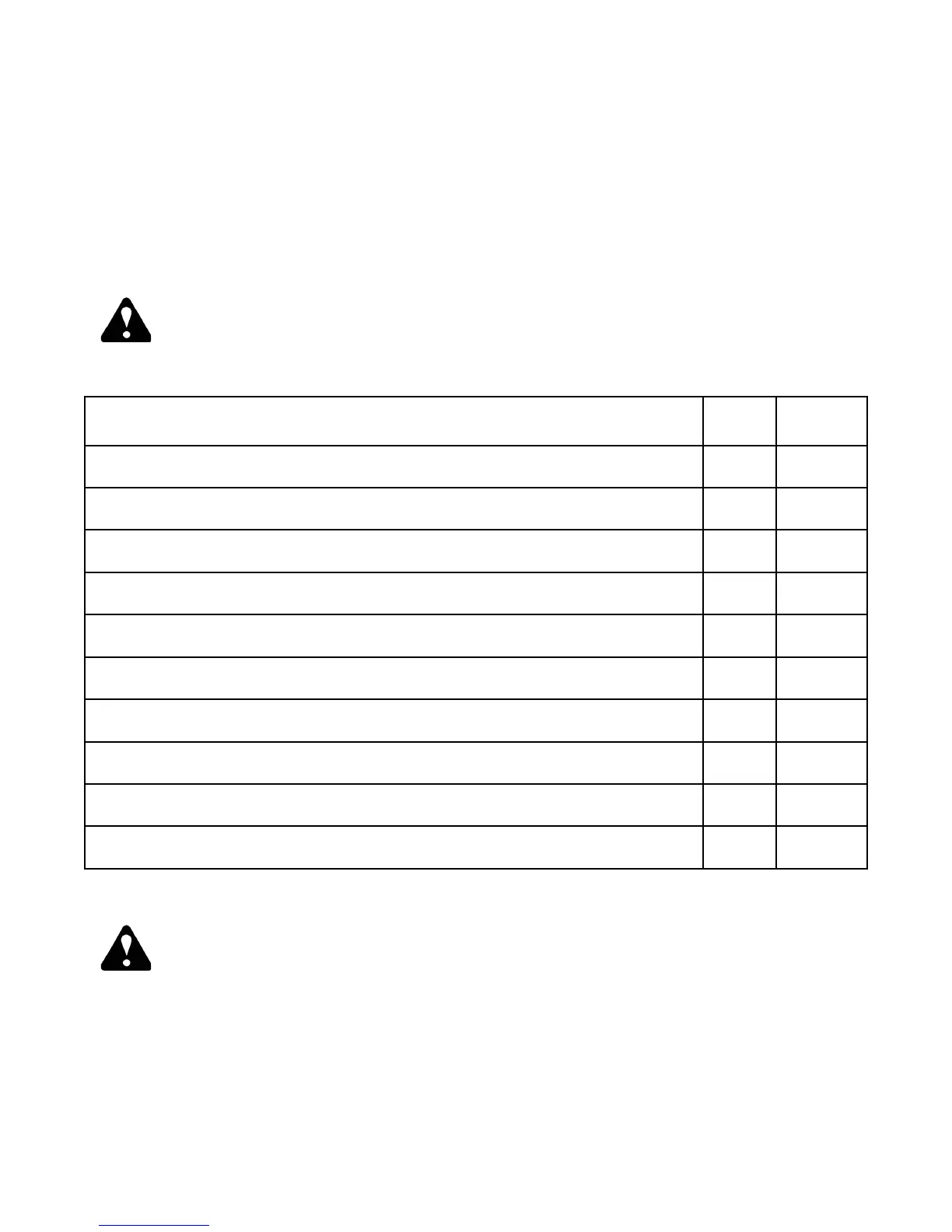

Procedure Daily Every 40

Hours

Check skid steer loader hydraulic system to ensure an adequate level of hydraulic oil.

Check Gearbox castle nut and torque to 250-350 ft. lbs (339-475 N

.

m).

Check mounting hardware on teeth and torque to 150- 180 ft. lbs (203-244 N

.

m).

Check all other hardware and tighten if necessary. (See Bolt Torque Specications)

Check hydraulic system for hydraulic oil leaks.

Check Gearbox power shaft for foreign material wrapped around the shaft and remove

if necessary.

Check teeth for damage and replace as needed.

Check all Safety Guards and Devices are installed correctly.

Check for missing or illegible Safety / Warning Decals.

Check oil level in gearbox and add if necessary. (See Lubrication Section)

WARNING! Escapinguidunderpressurecanhavesufcientforcetopenetratethe

skin causing serious personal injury. Fluid escaping from a very small

hole can be almost invisible. Use a piece of cardboard or wood, rather that

hands to search for suspected leaks.

Keep unprotected body parts, such as face, eyes, and arms as far away as

possiblefromasuspectedleak.Fleshinjectedwithhydraulicuidmay

develop gangrene or other permanent disabilities.

Ifinjuredbyinjecteduid,seeadoctoratonce.Ifyourdoctorisnotfamil-

iar with this type of injury, ask him to research it immediately to determine

proper treatment.

9727 7-29-14-2

Loading...

Loading...